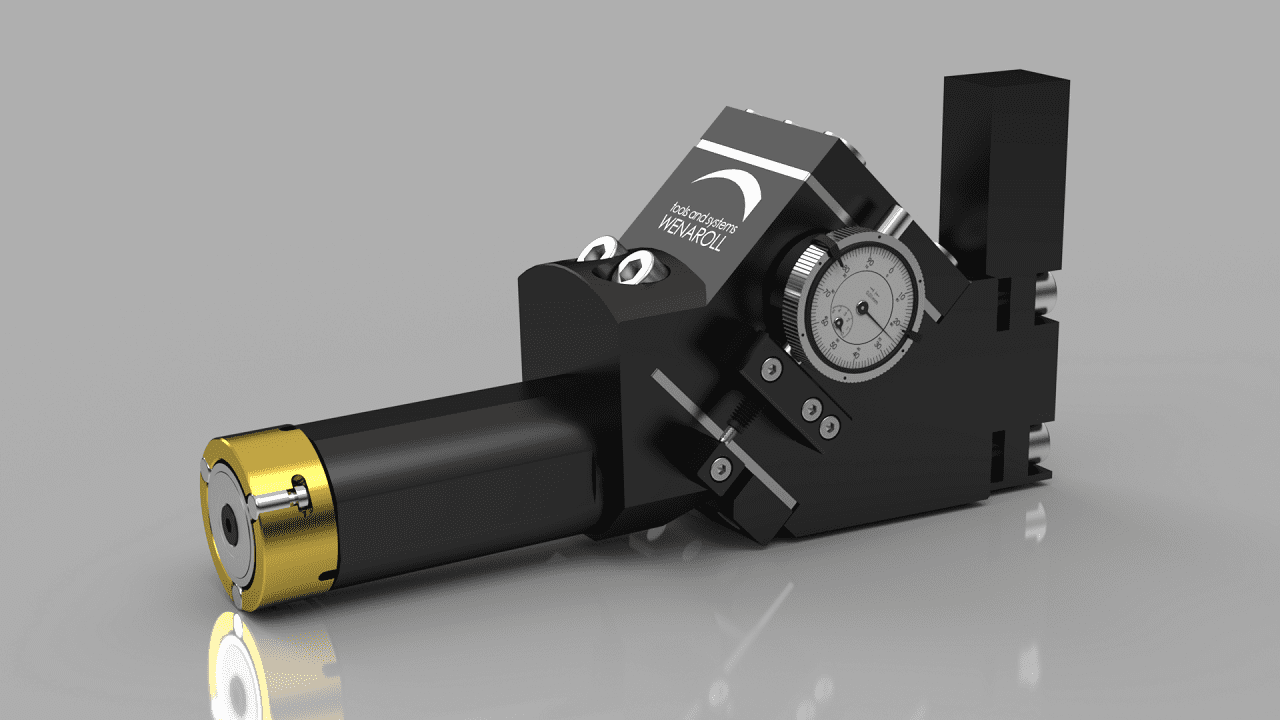

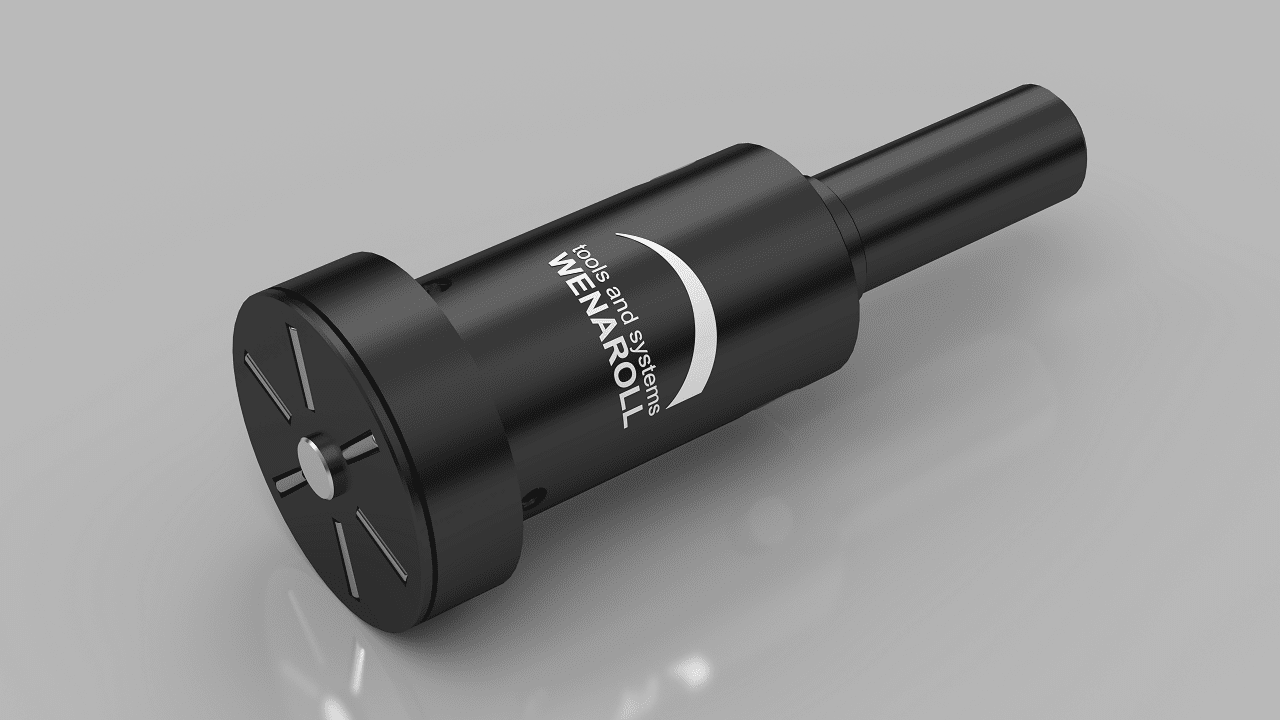

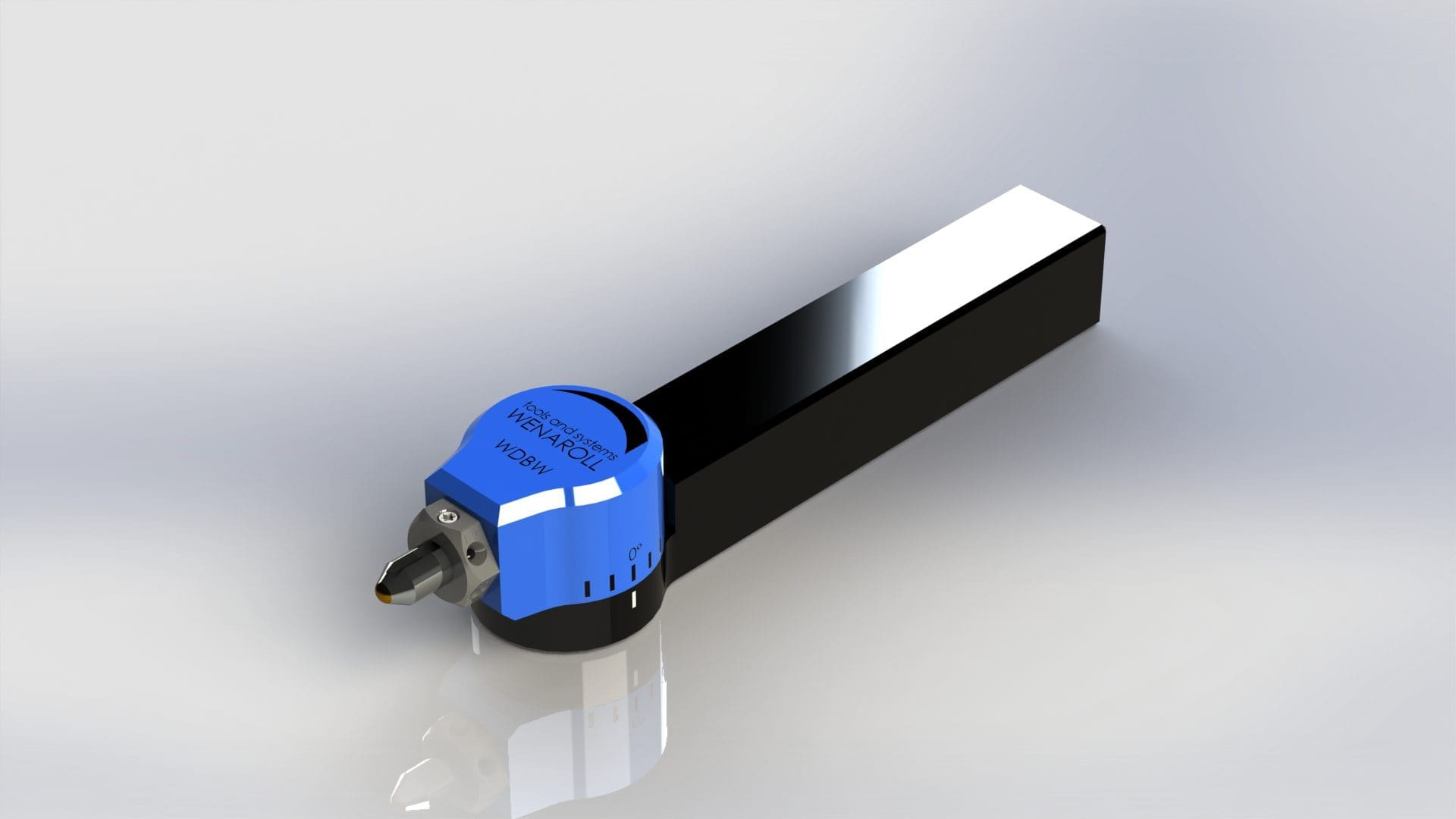

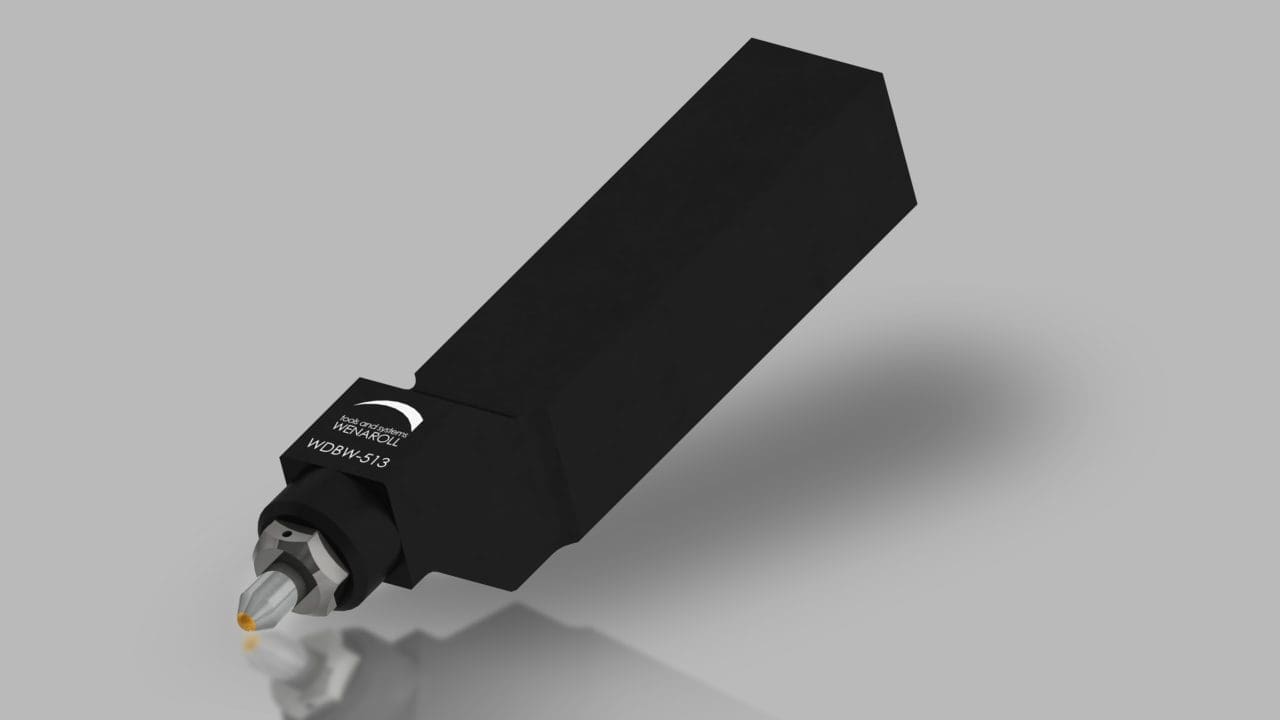

Type WHS

- Surfaces with a quality of Rz < 1 µm can be produced quickly

- Long lifetime for wear parts

- Chipless and quiet process

- Wear parts can be exchanged quickly

- Micro surface structure remains intact

- Brought in residual compressive stress

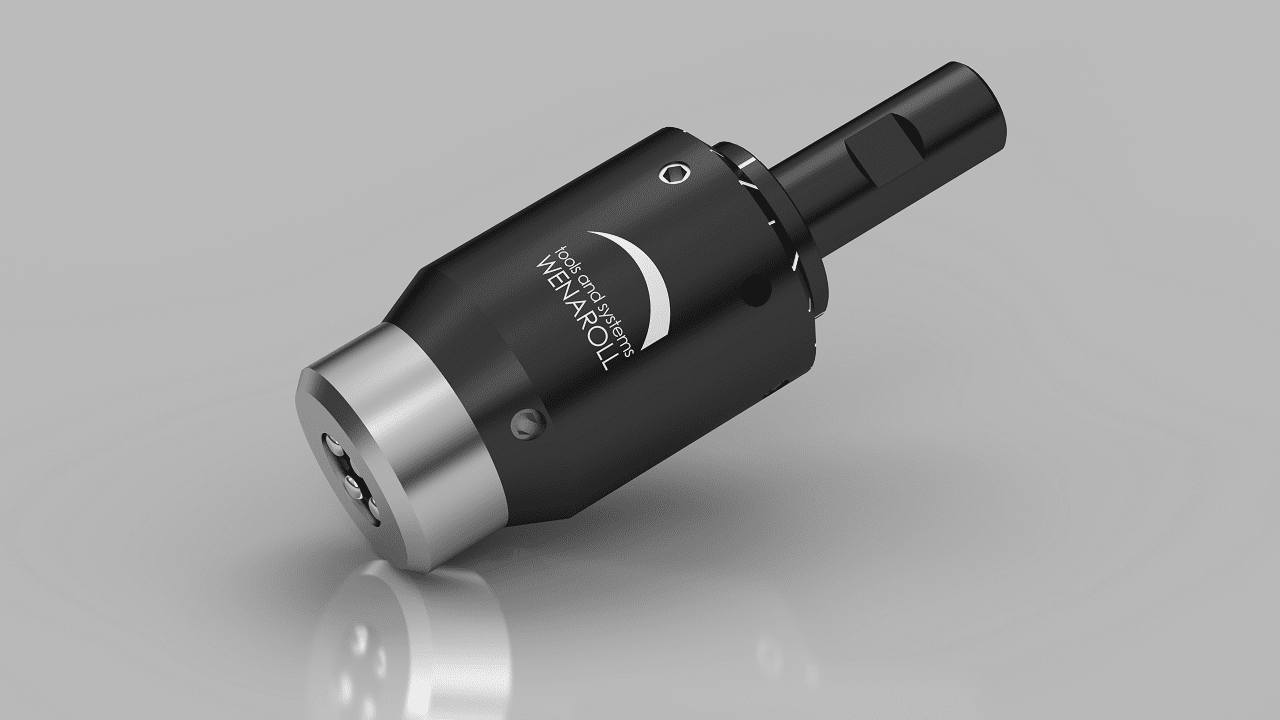

WHS-PT3-20,00-25-HSK63

- WHS-PT3 | Tool body

- 20,00 | Work piece diameter

- 25 | Processing depth

- HSK63 | Tool shank

Description

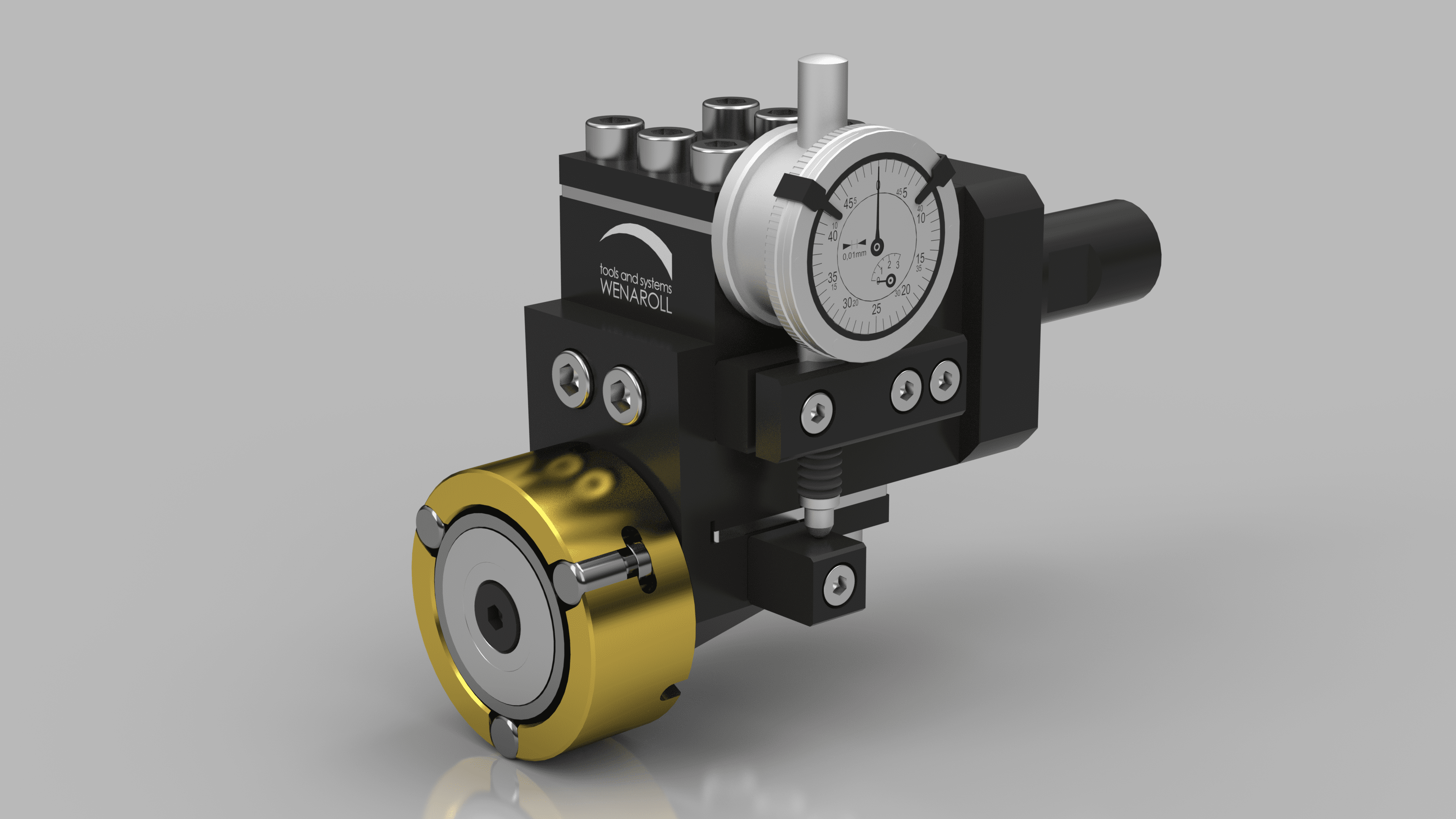

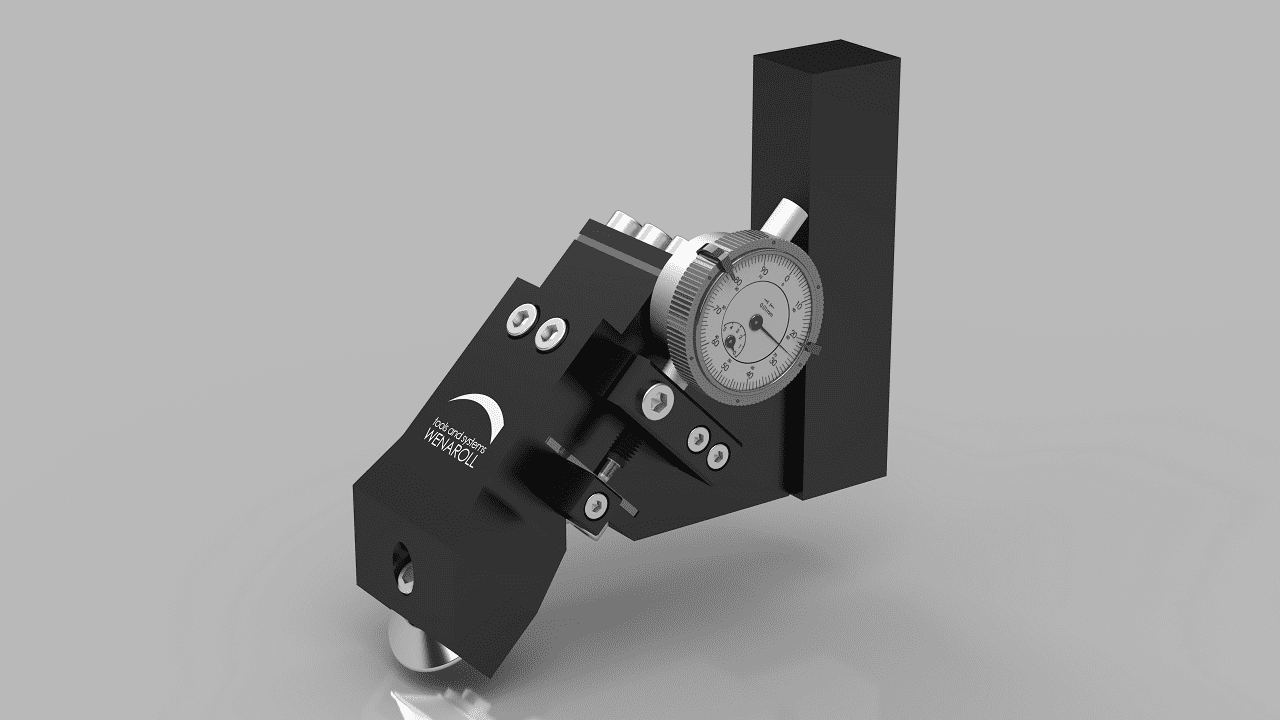

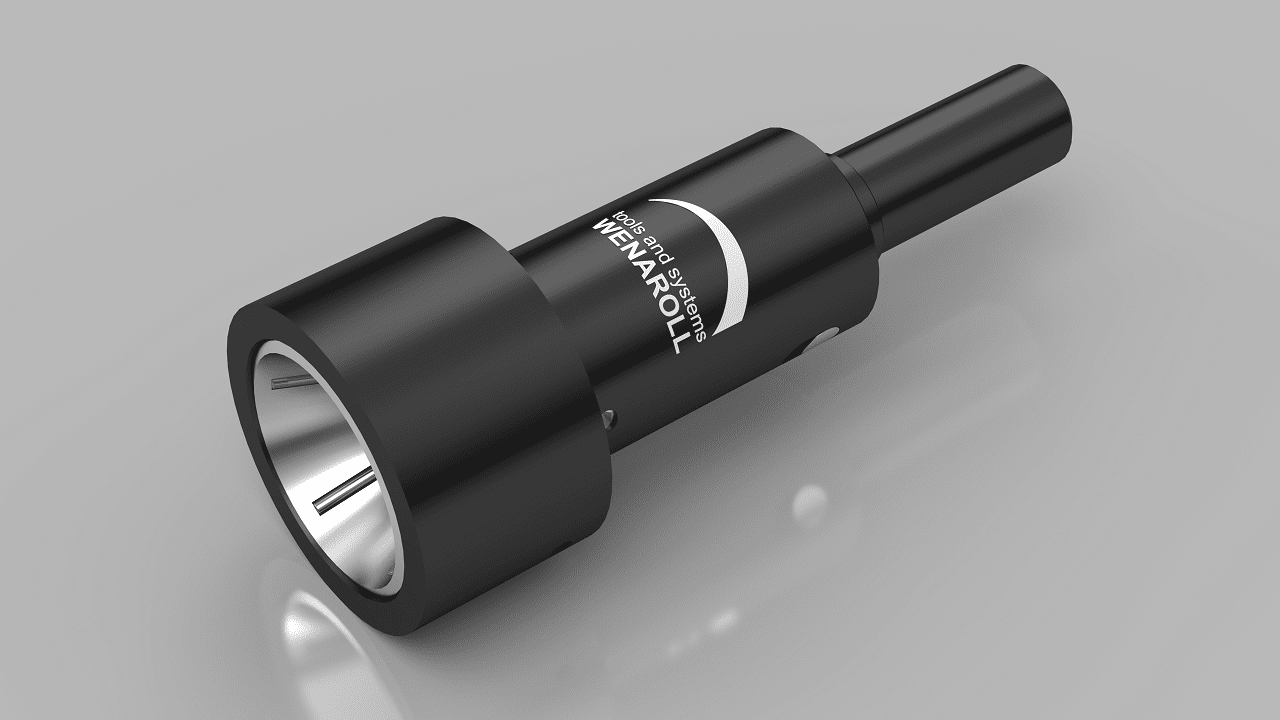

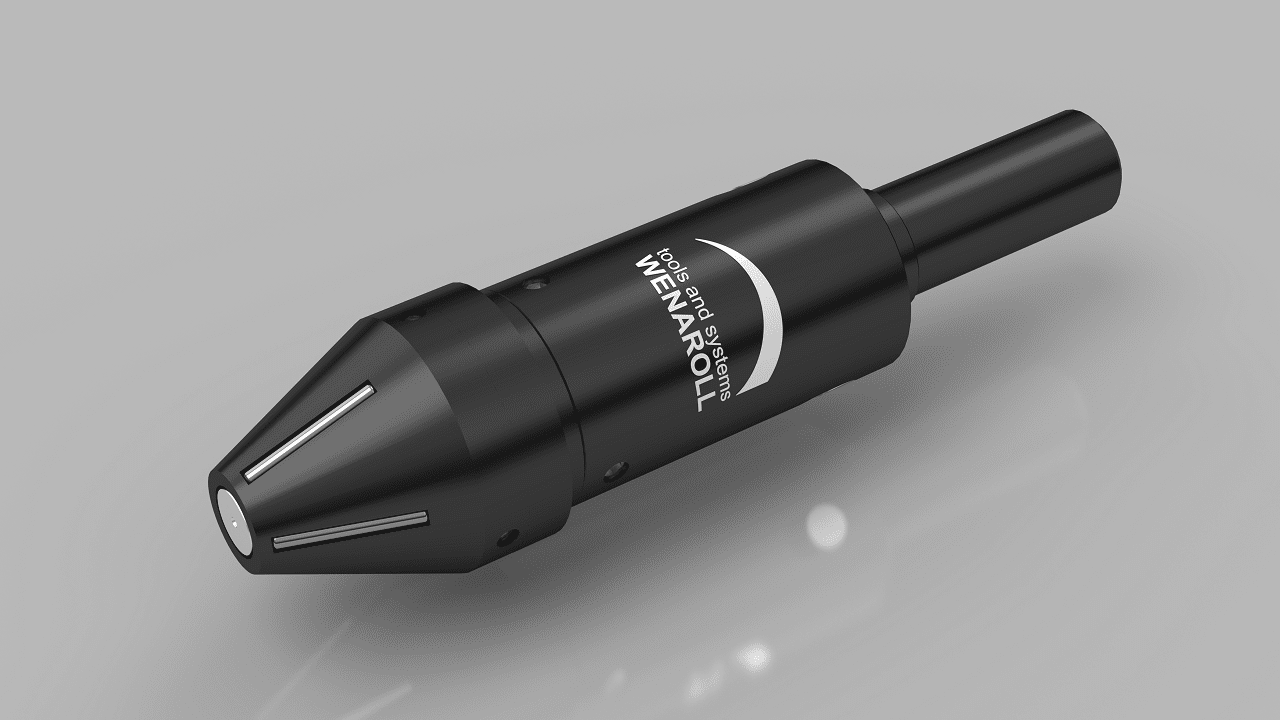

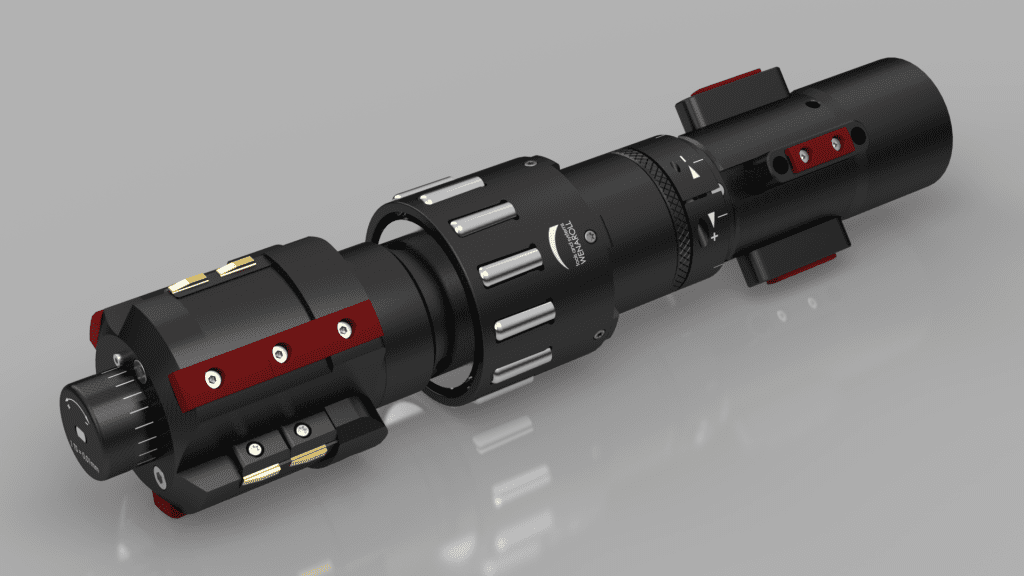

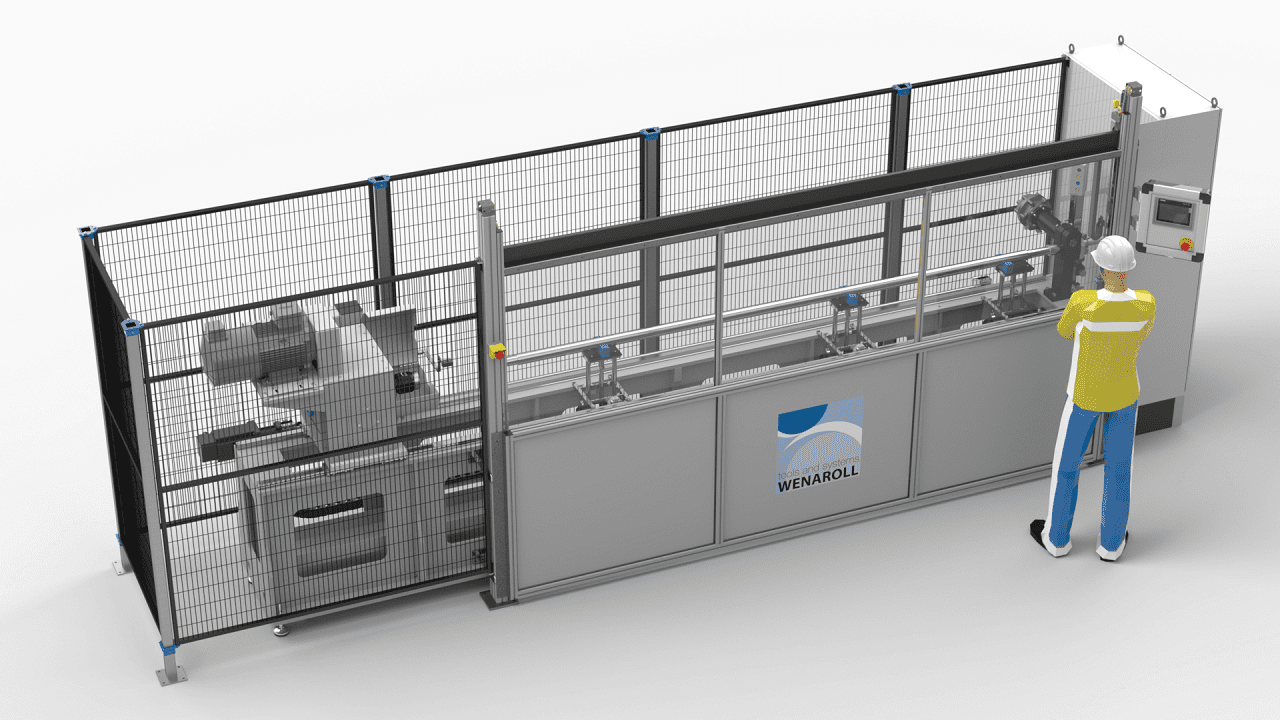

Wenaroll Type WHS hydrostatic Tools are used for precision machining of drill holes. Cooling lubricant is used to force one or more spheres against the work piece surface. The process will smoothen the surface and induce residual compressive stress.

These tools can be used to machine work pieces with a hardness of up to 65 HRC, thus making them much more versatile. The process only requires a sufficient coolant pressure, which can either be supplied directly through the spindle (IKZ), or by an external pump. These tools can be used on manual / CNC lathe or milling machines.

For very small process diameters a pressure of up to 400 bar can be necessary.

For additional information on applications and process requirements please get in touch with us either via E-Mail or phone.

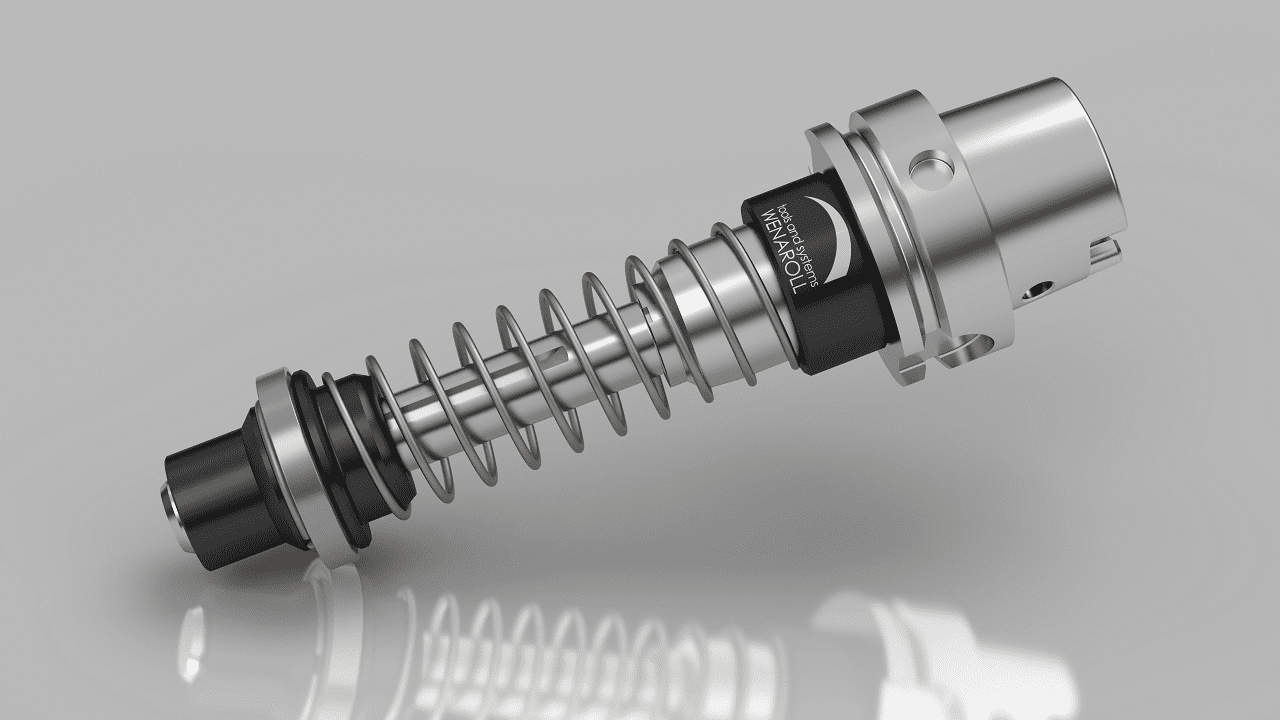

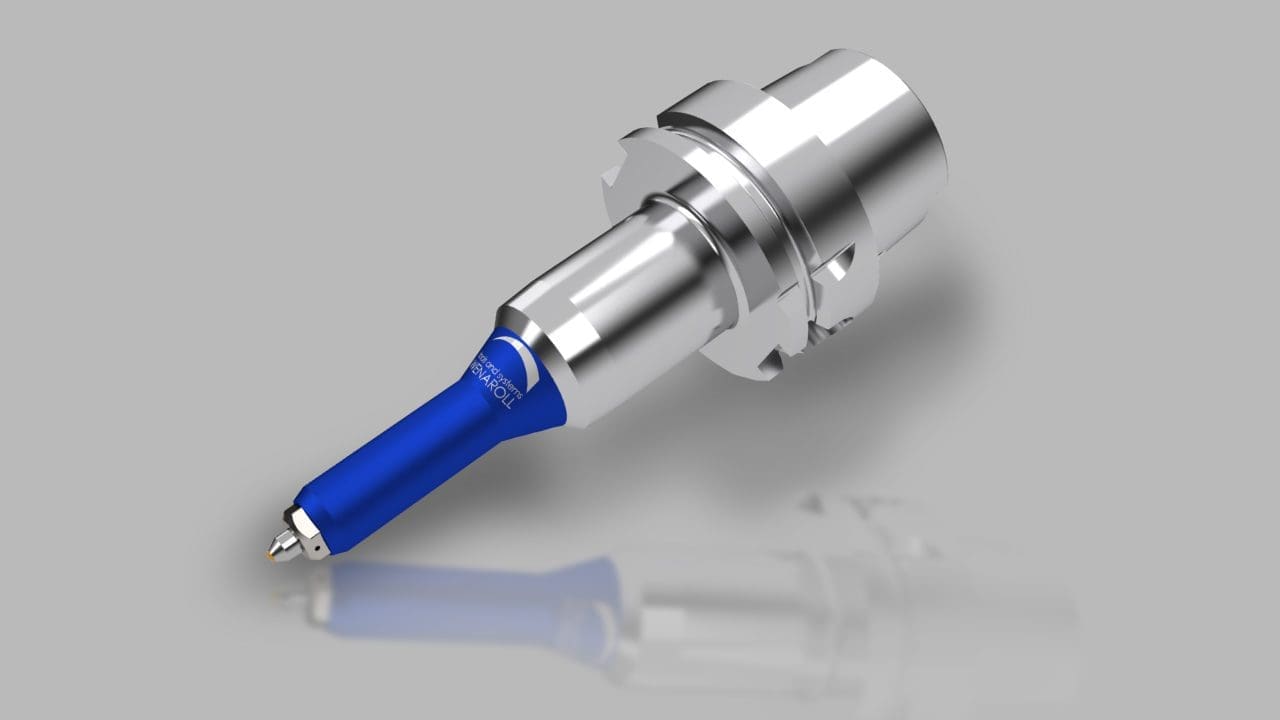

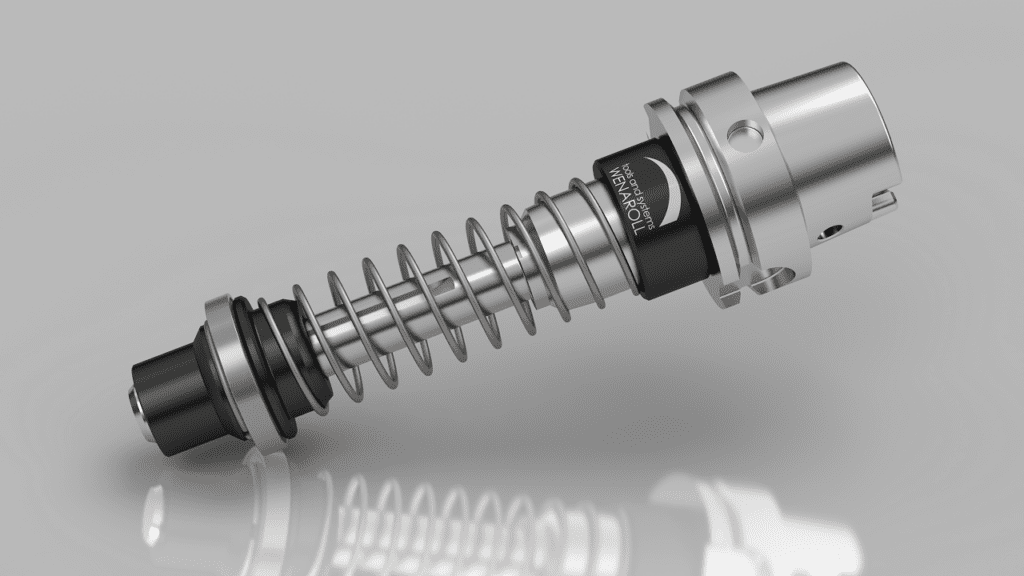

Tool structure

The Wenaroll WHS type tools consist of a carrier shaft for holding the balls and a receptacle that is designed according to your requirements. The coolant is usually supplied through the fixture and the tool can also be connected to an external pump directly to the tool in special cases.

Process

During the process the tool or the work piece has to rotate and pressure needs to be applied to the tool. The rotation and the force of the sphere smoothen and compress the surface.

The movement of the sphere is not mechanically limited, thus allowing the tool to create a uniform result. This is even more interesting if the surface has a pre-machined micro-structure that must be present after the burnishing process.