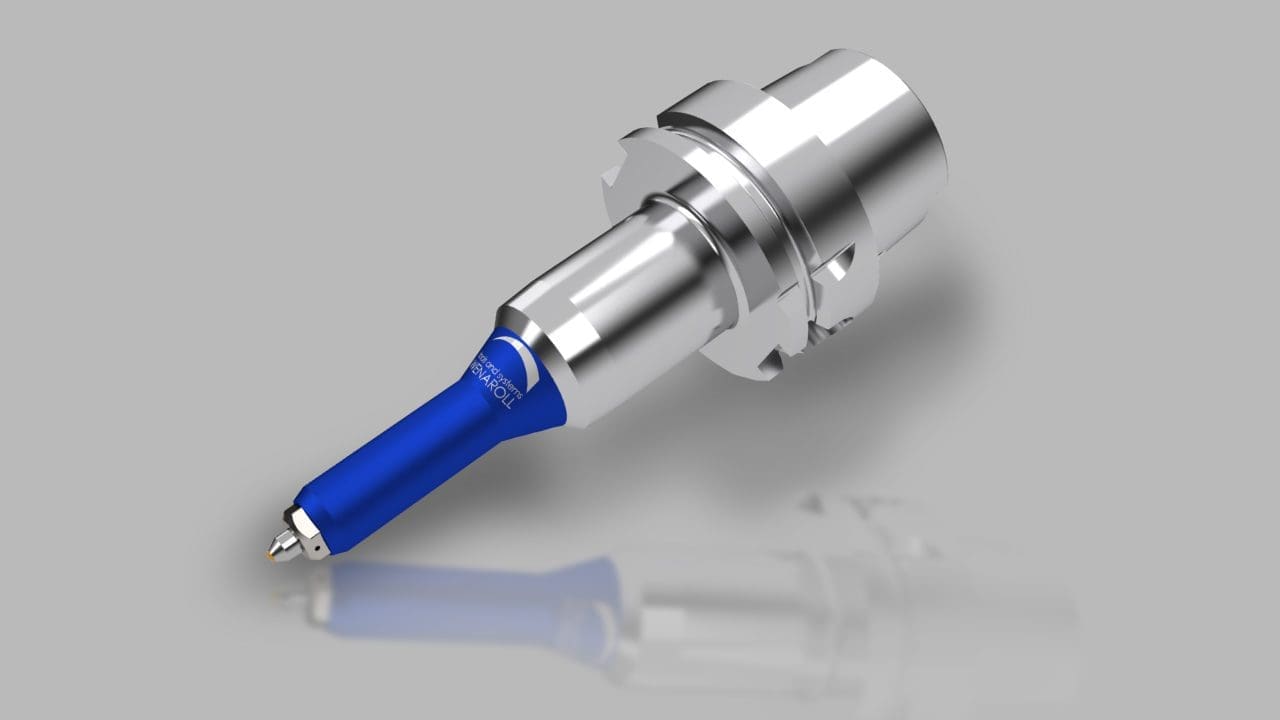

Type WIW Ø 4 – Ø 350 mm

- Surfaces with a roughness of Rz < 1 µm are produced quickly

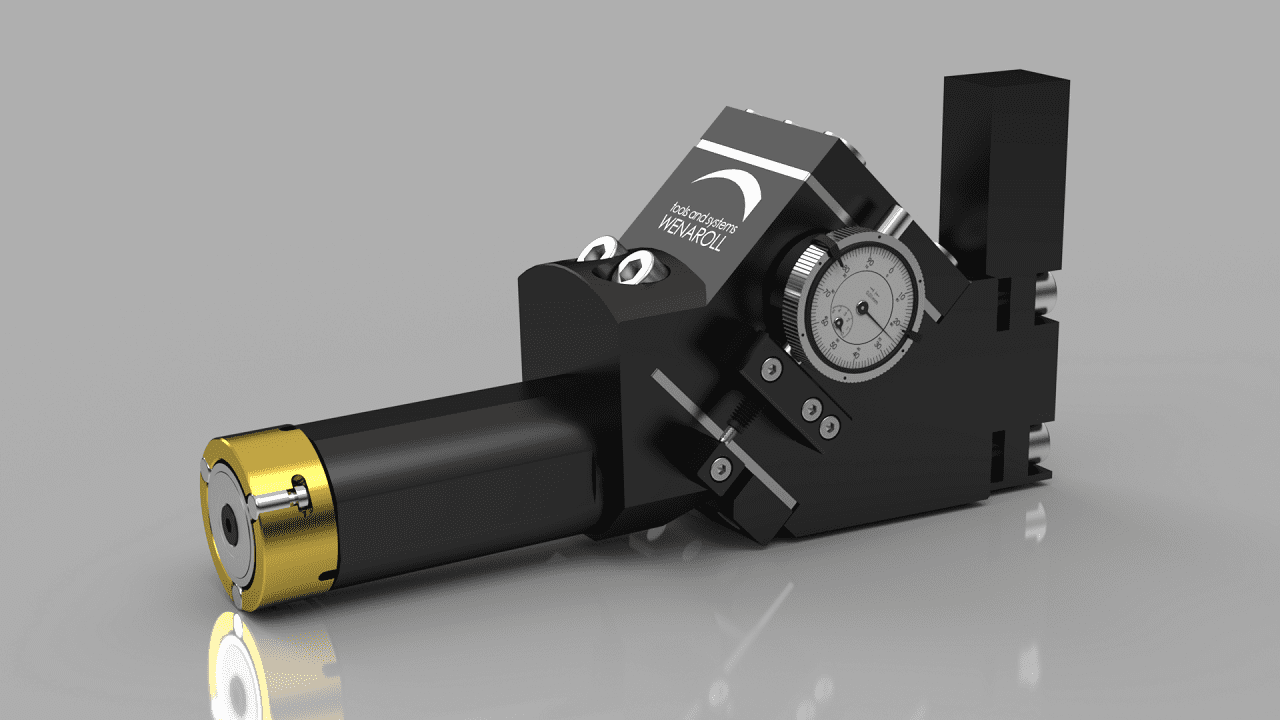

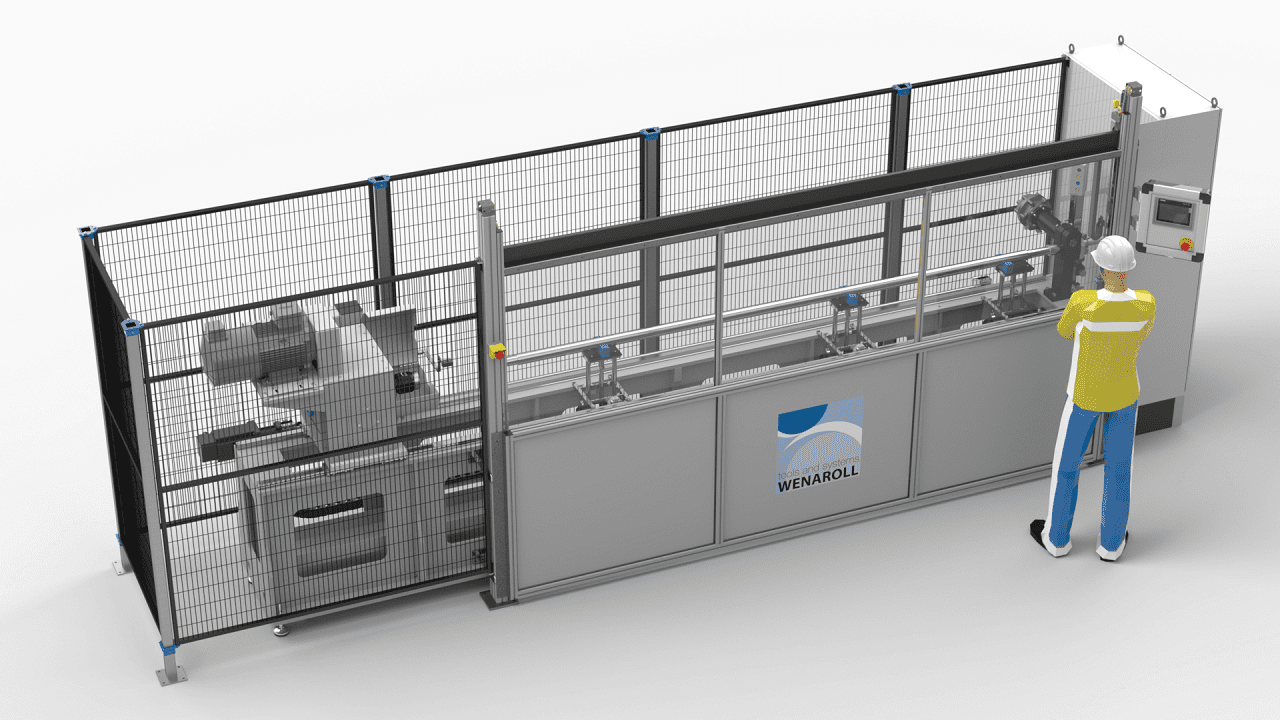

- Can be used on almost every machine

- Long lifetime for wear parts

- Chipless and quiet process

- Wear parts can be exchanged quickly

- Barely any lubricant / cooling required

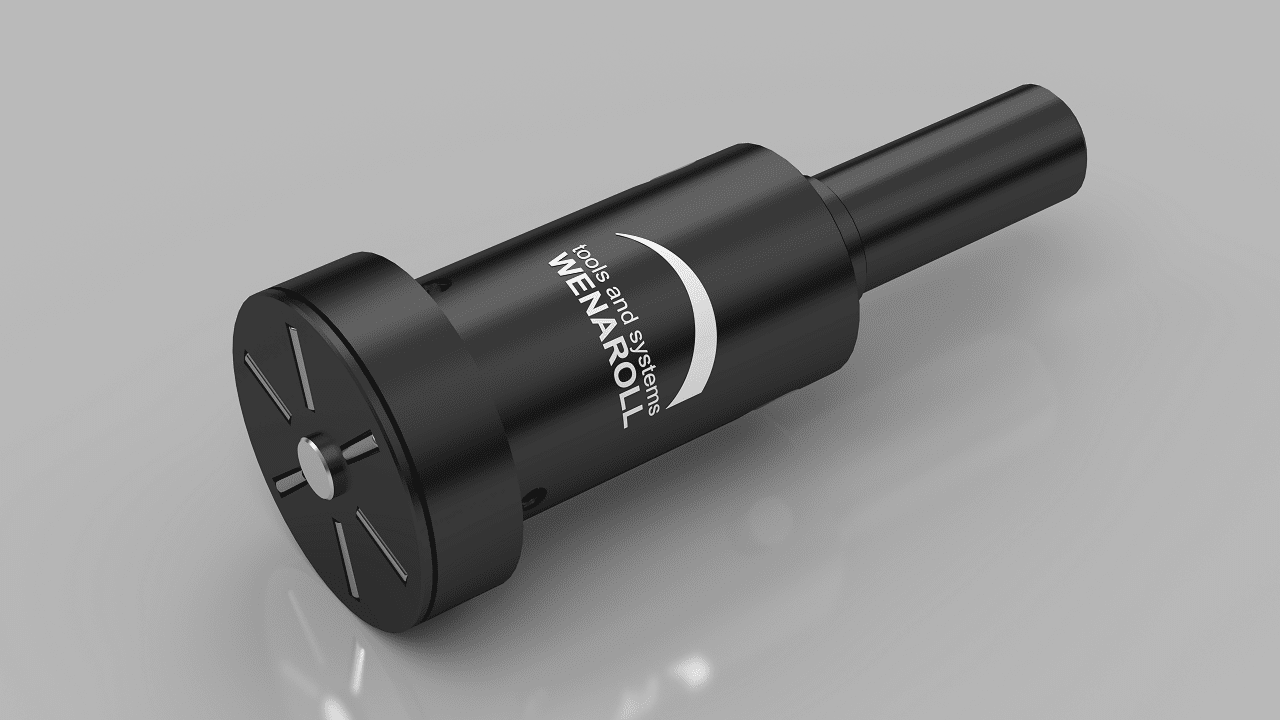

- Quick diameter adjustment

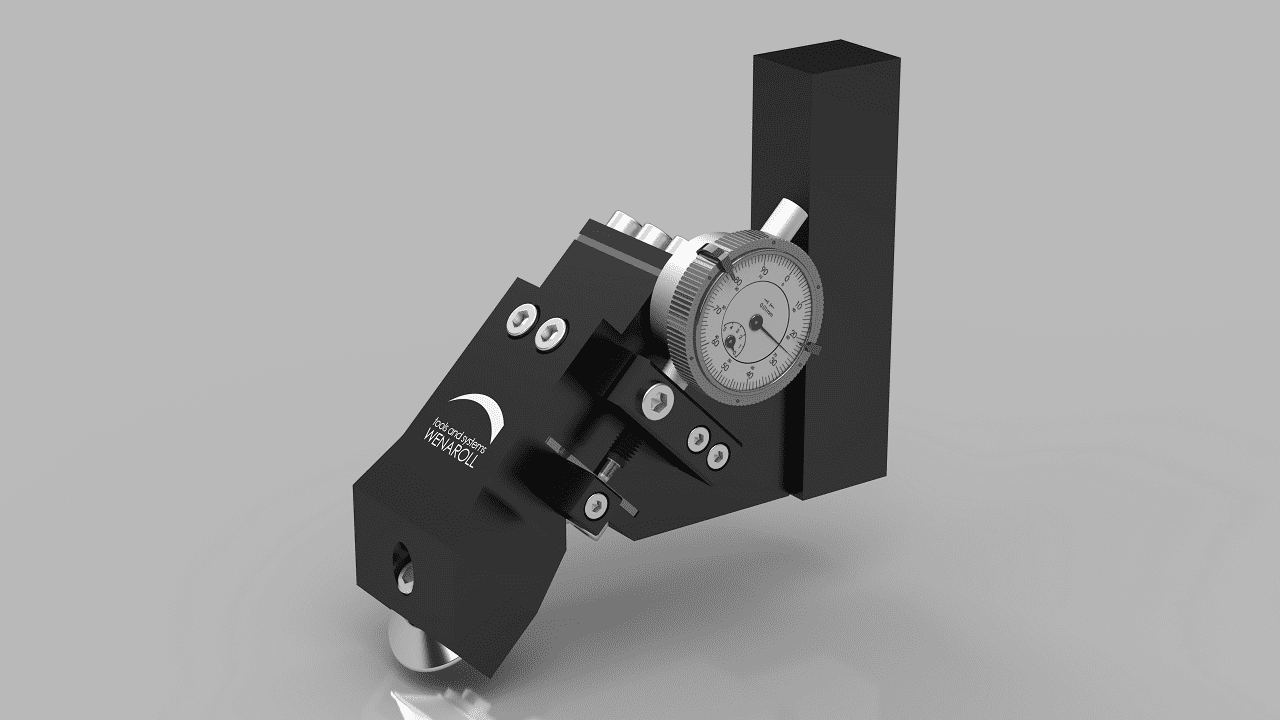

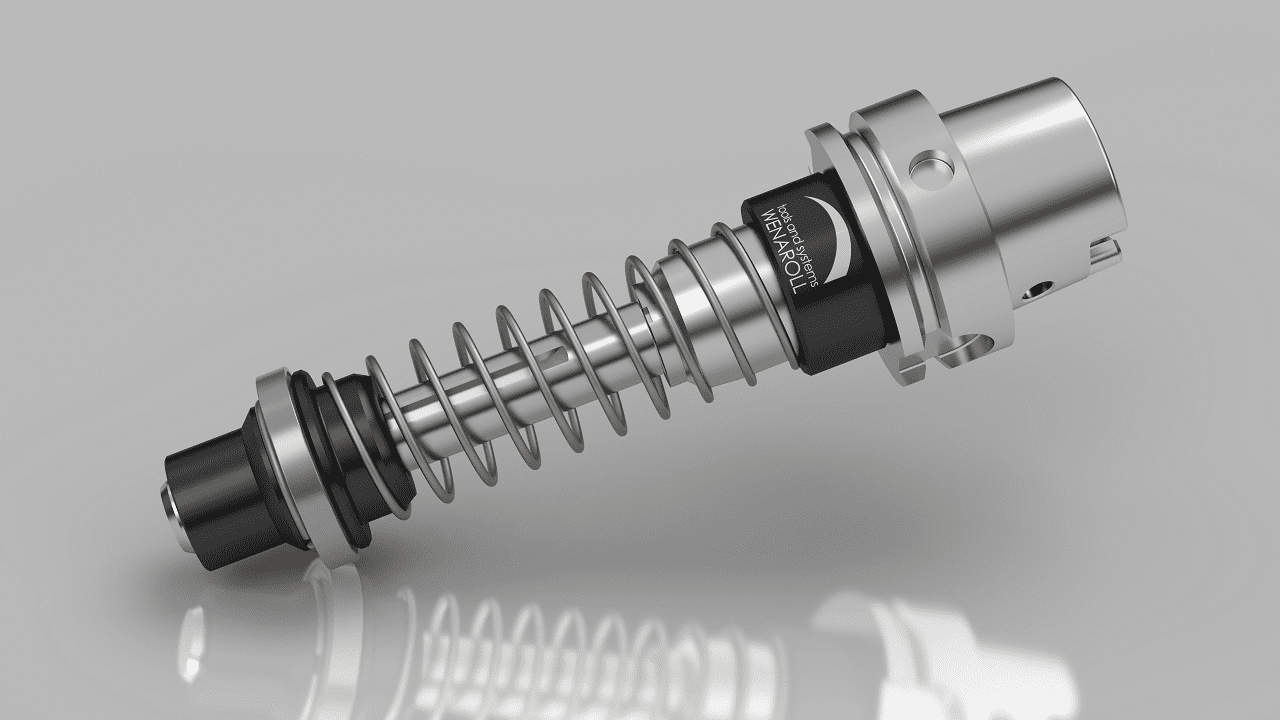

- No surface damage during tool retraction due to spring relief system

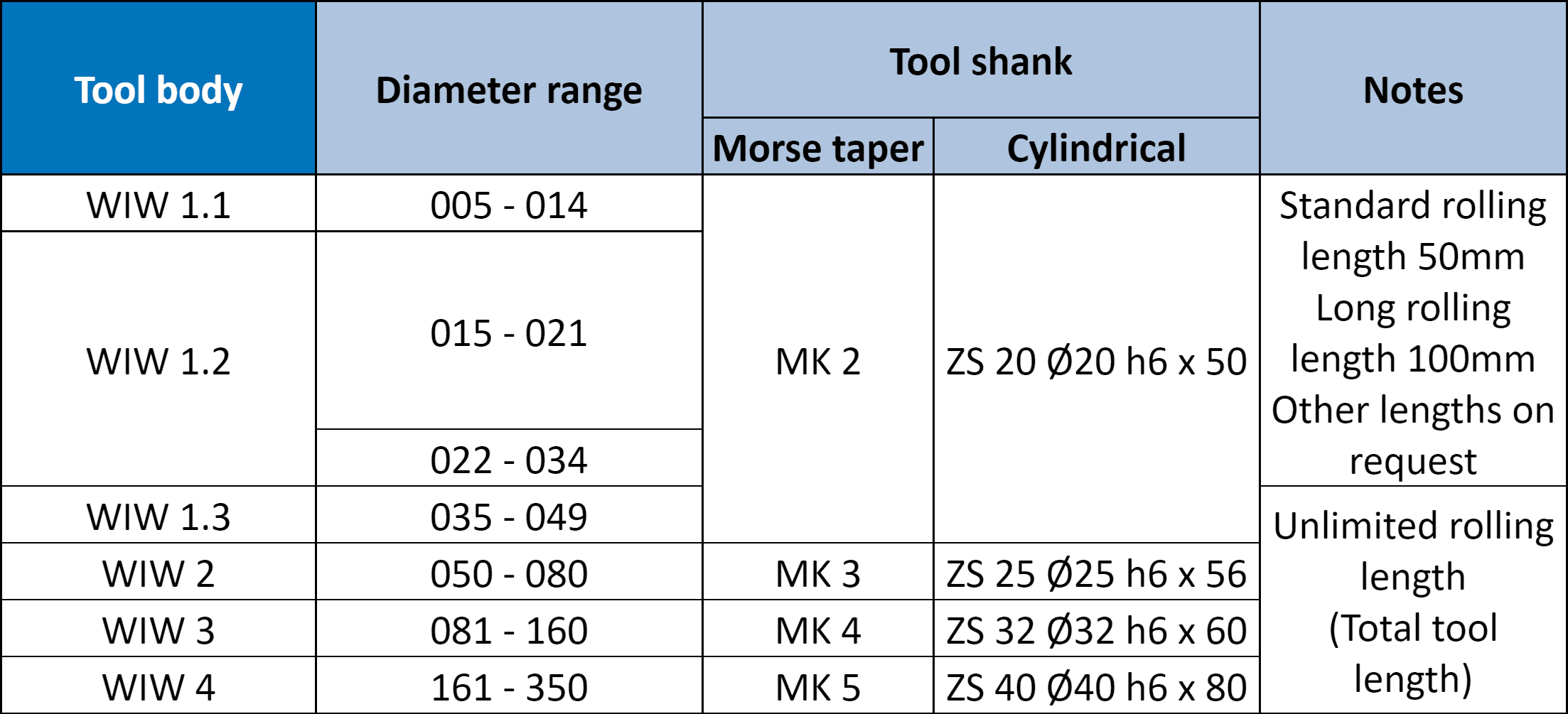

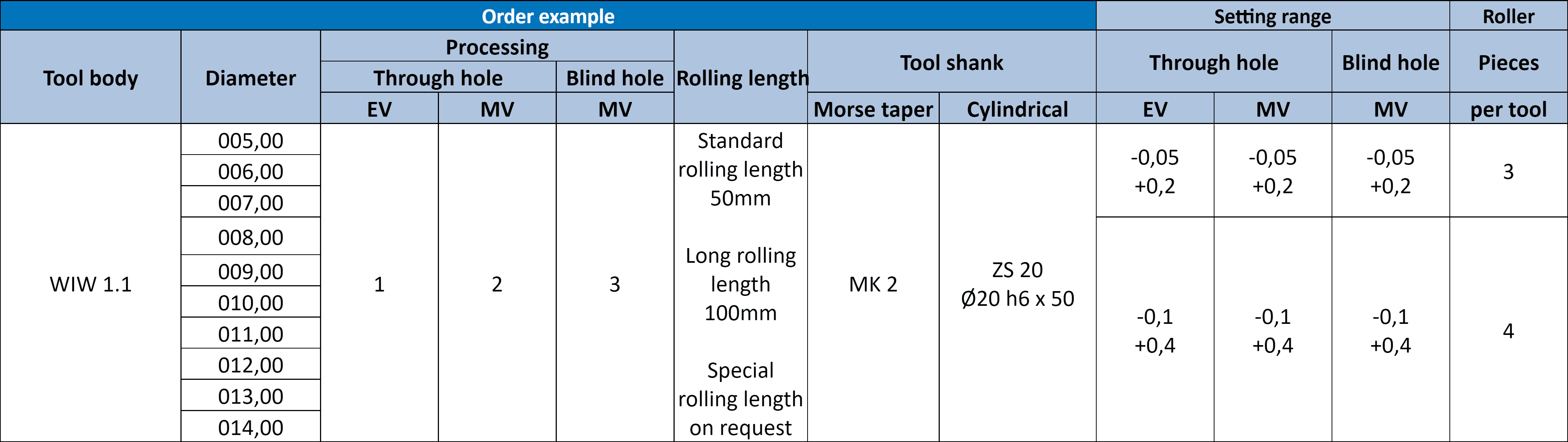

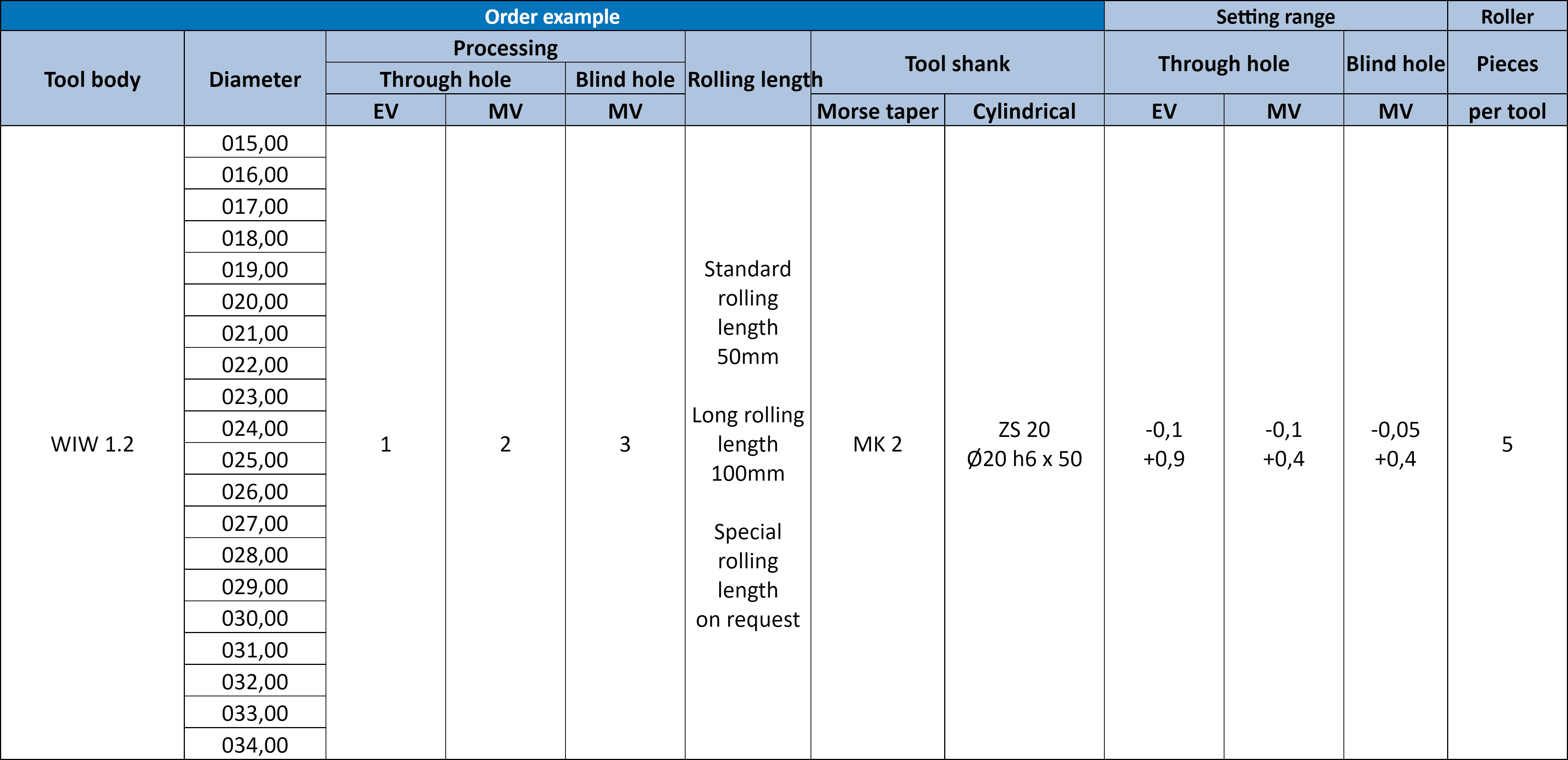

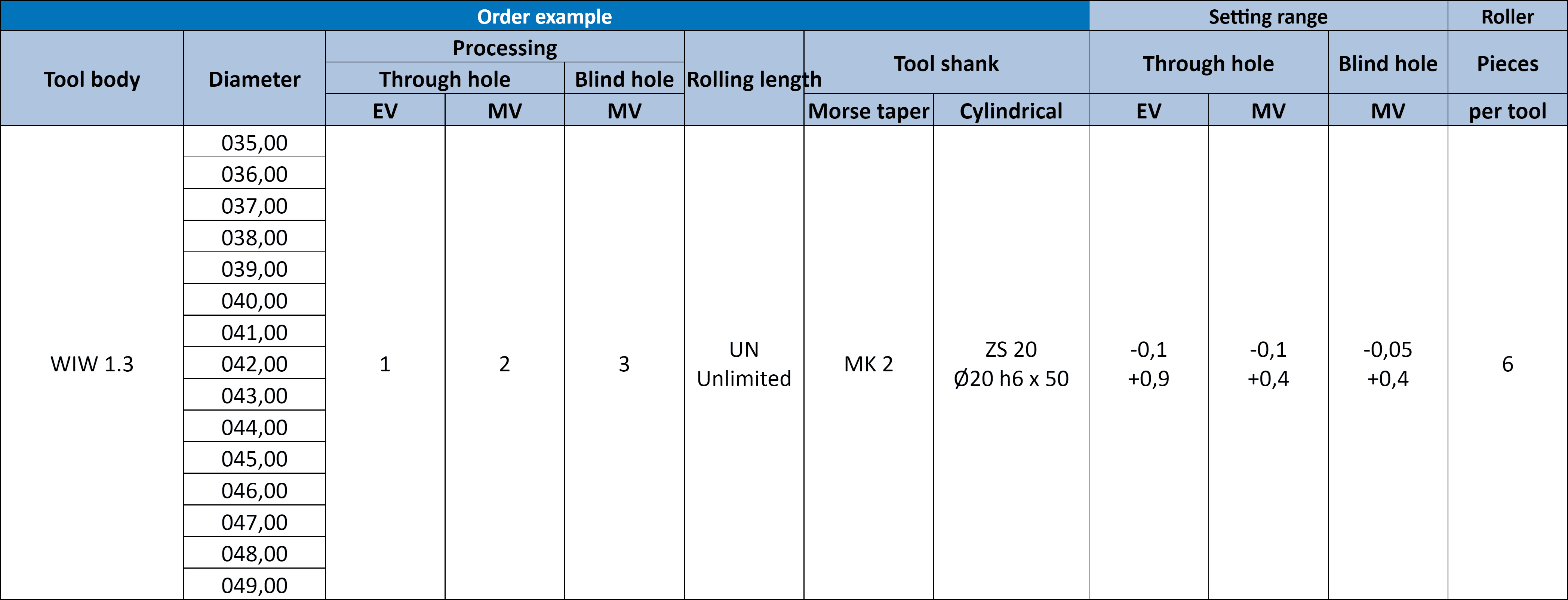

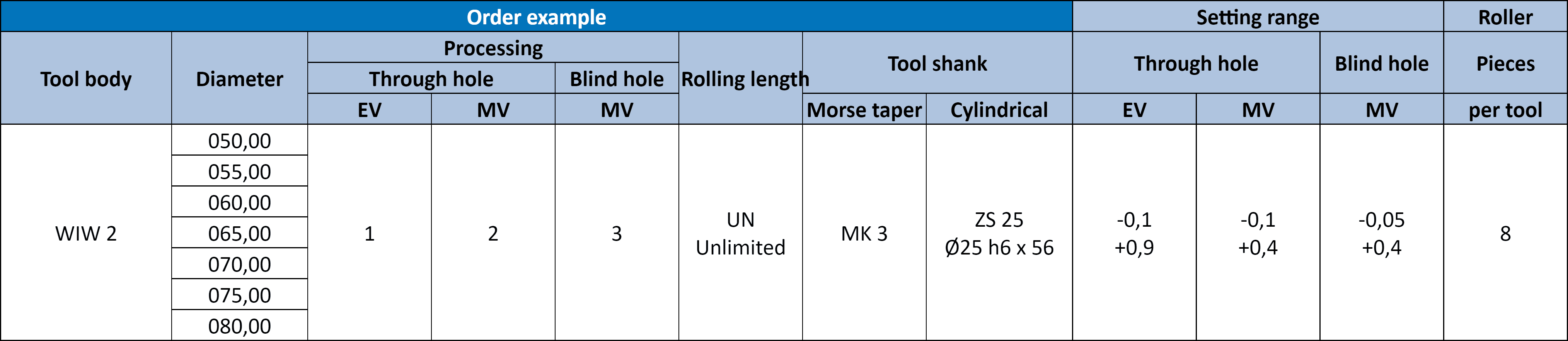

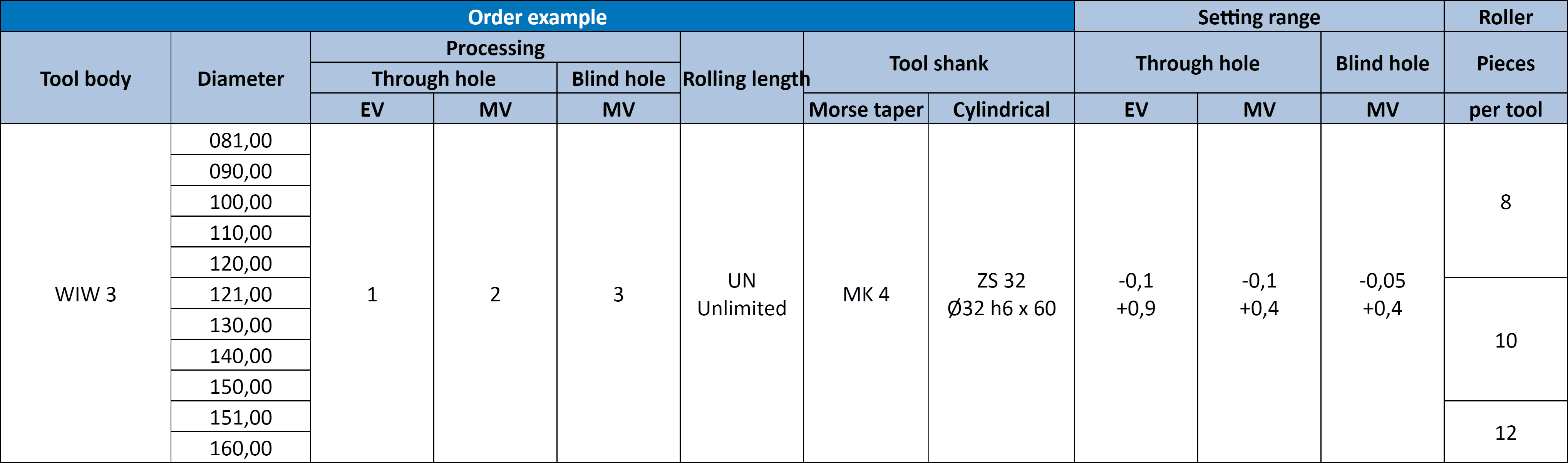

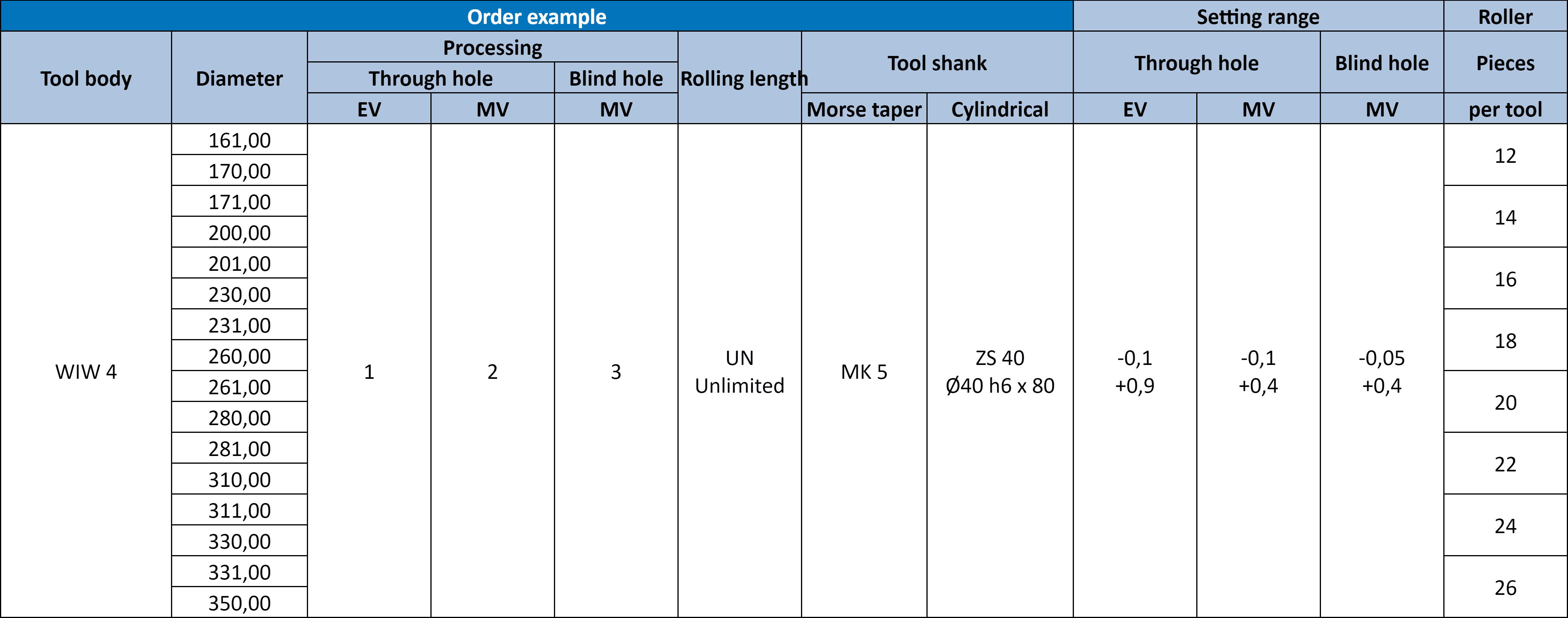

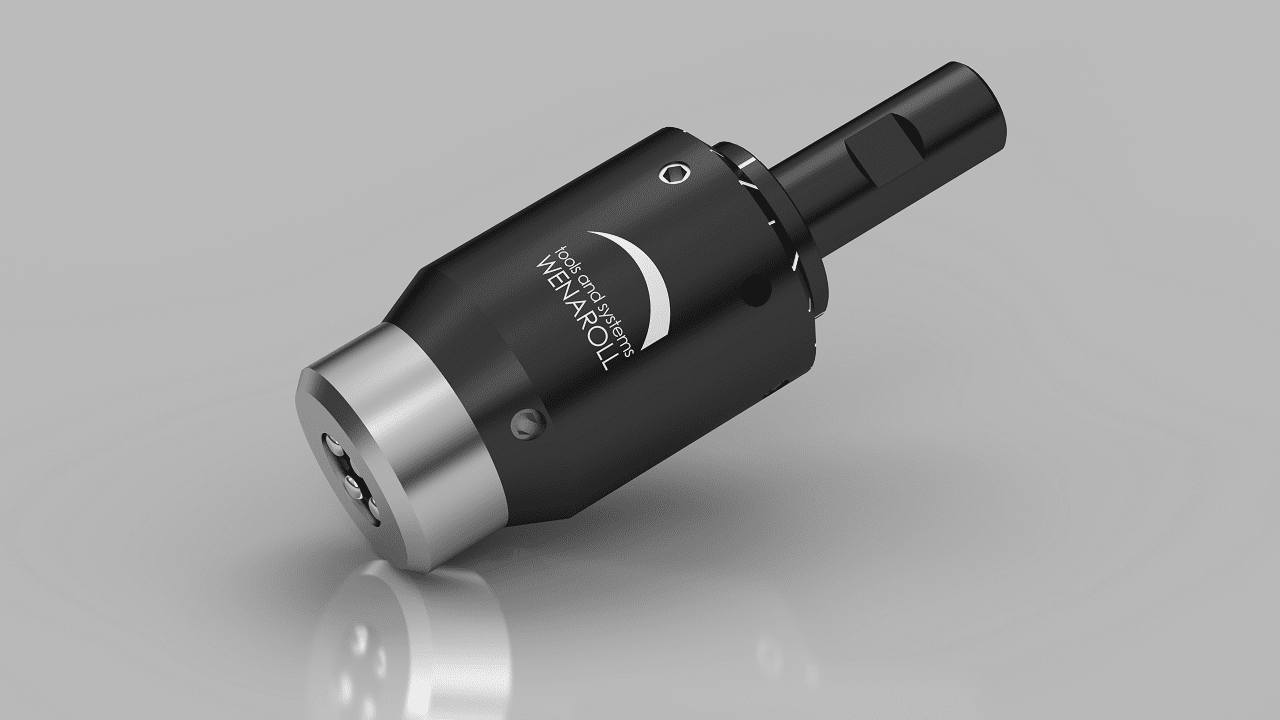

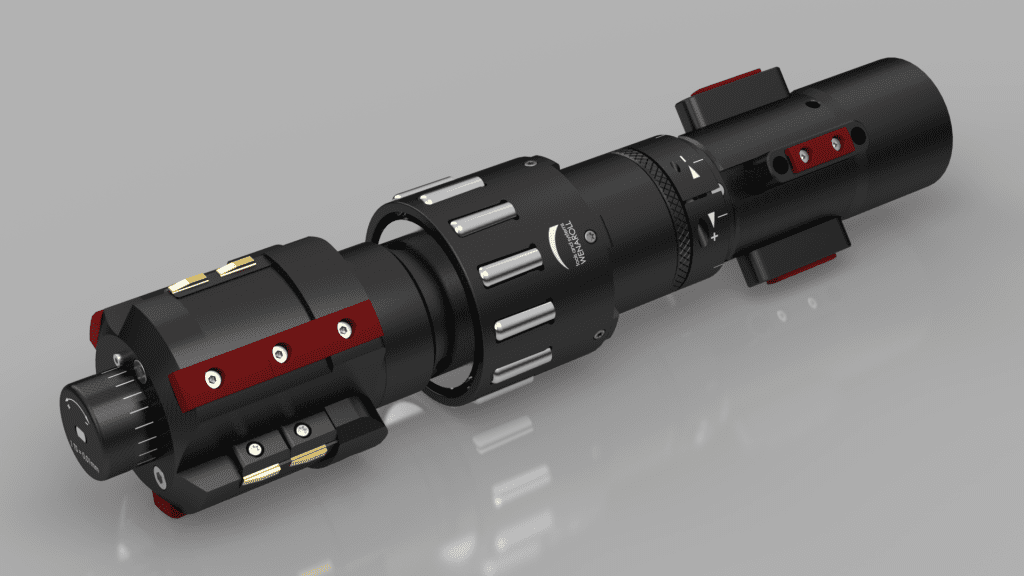

WIW1.2.-025,00-1-100-ZS20

- WIW1.2 | Tool body

- 025,00 | Diameter 25

- 1 | Through hole process with self feeding

- 100 | Max. burnishing depth 100mm

- ZS20 | Tool shank cylindrical Ø20 h6 x 50

Description

Wenaroll type WIW roller burnishing tools are used for cylindrical drill holes produce a fit with only one operation. During the process either the work piece or the tool can rotate. To satisfy our customers’ needs for precision the tools can be adjusted freely on a micro millimeter scale.

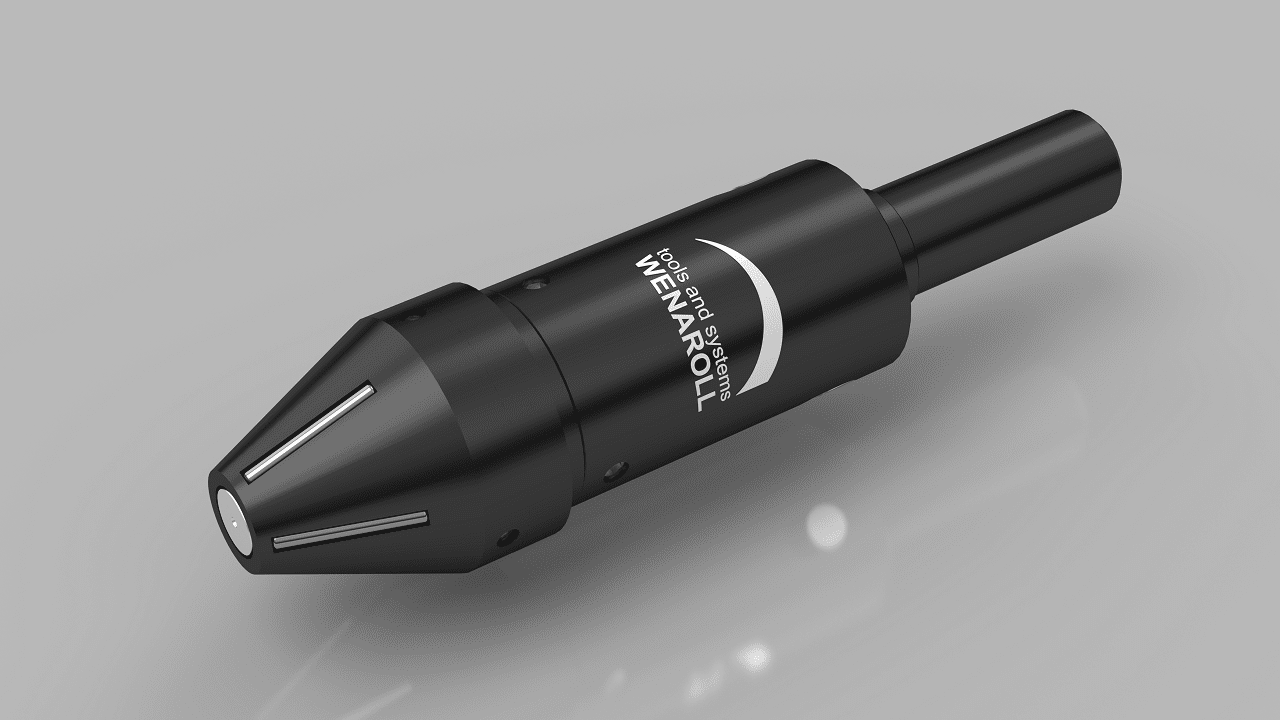

WIW type tools can be ordered for through hole or blind hole applications. Through hole tools can be used either with manual feed or machine feed, blind hole tools are only suitable for machine feed.

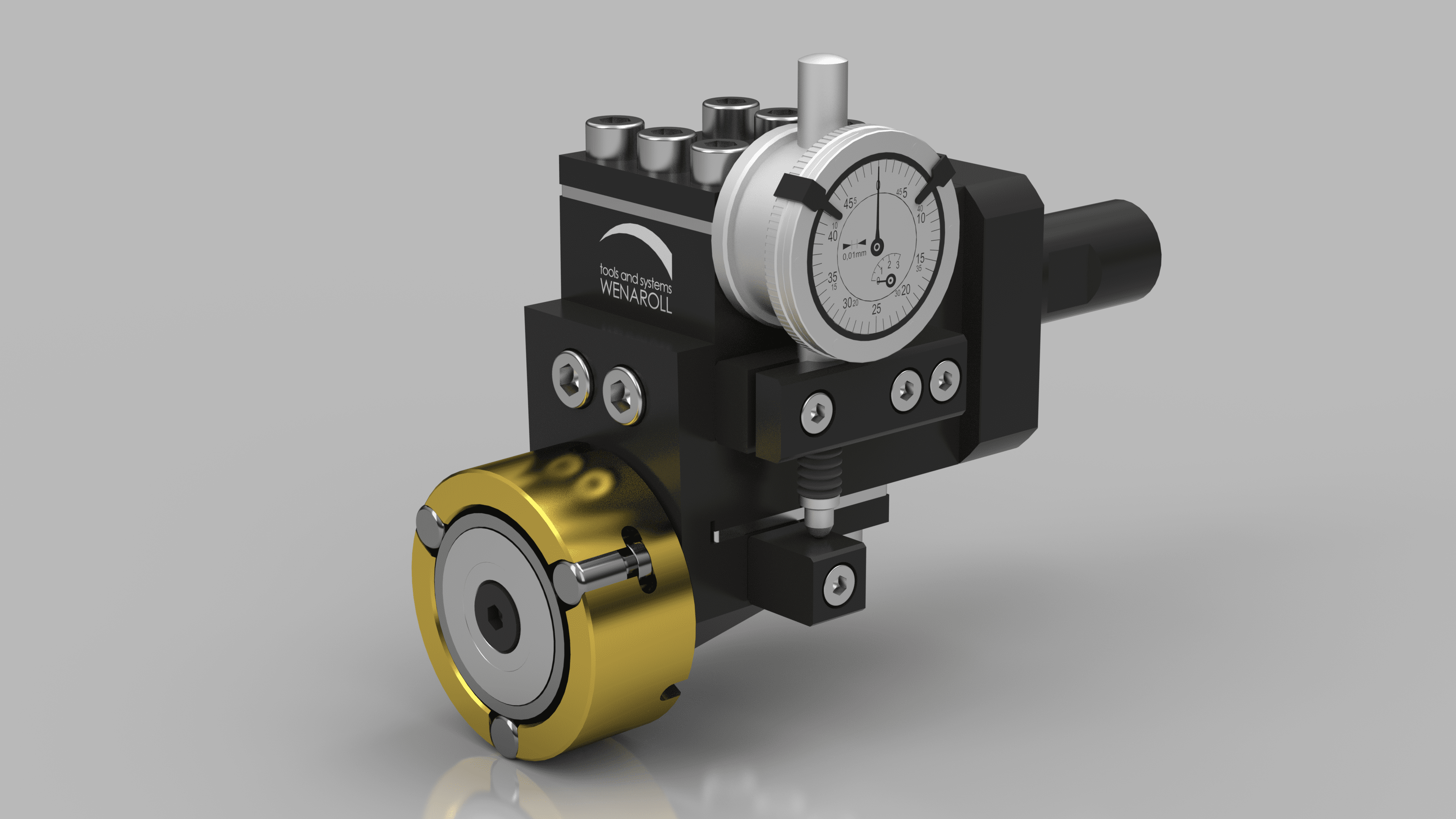

Tool structure

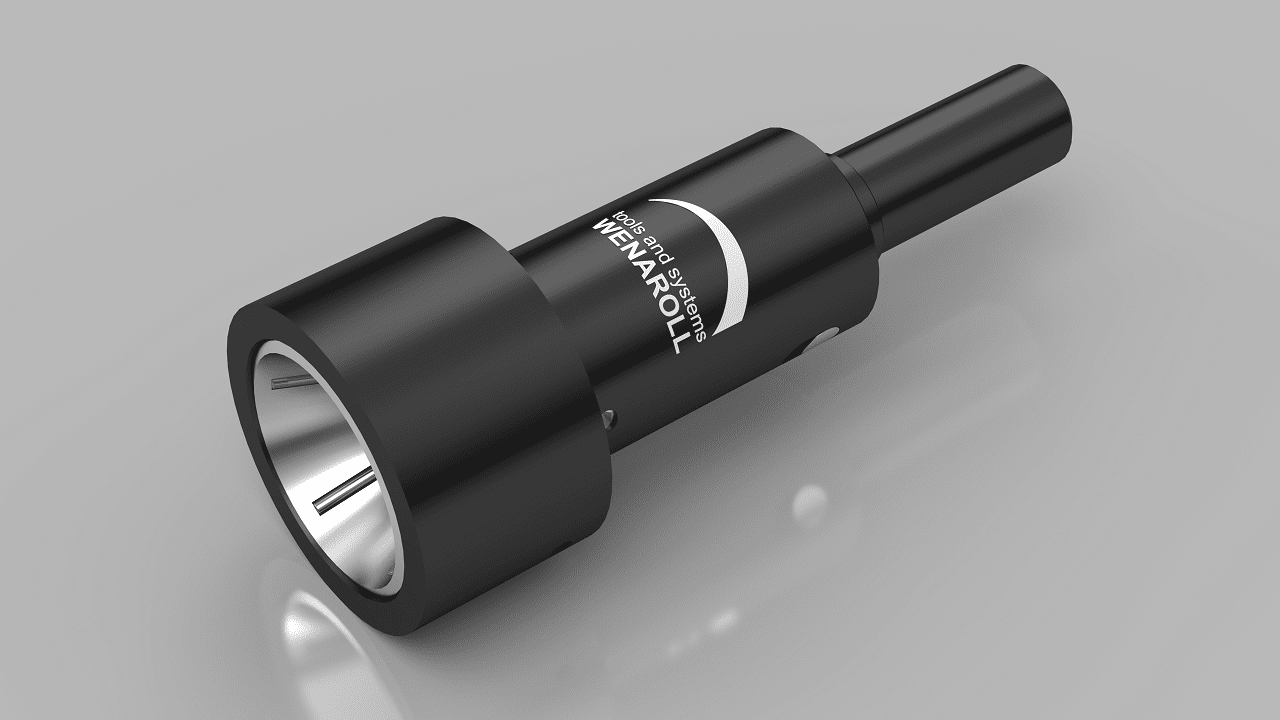

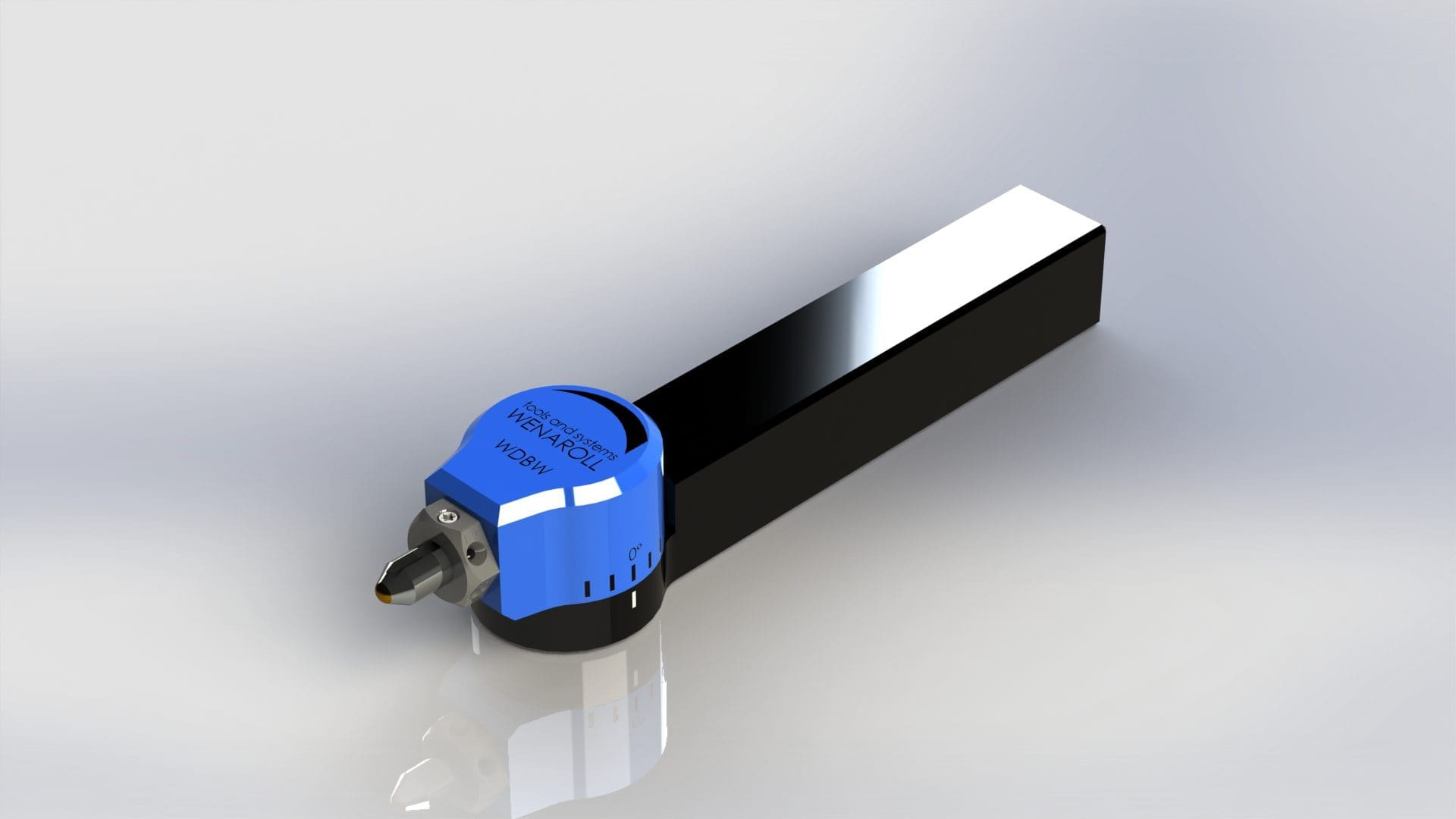

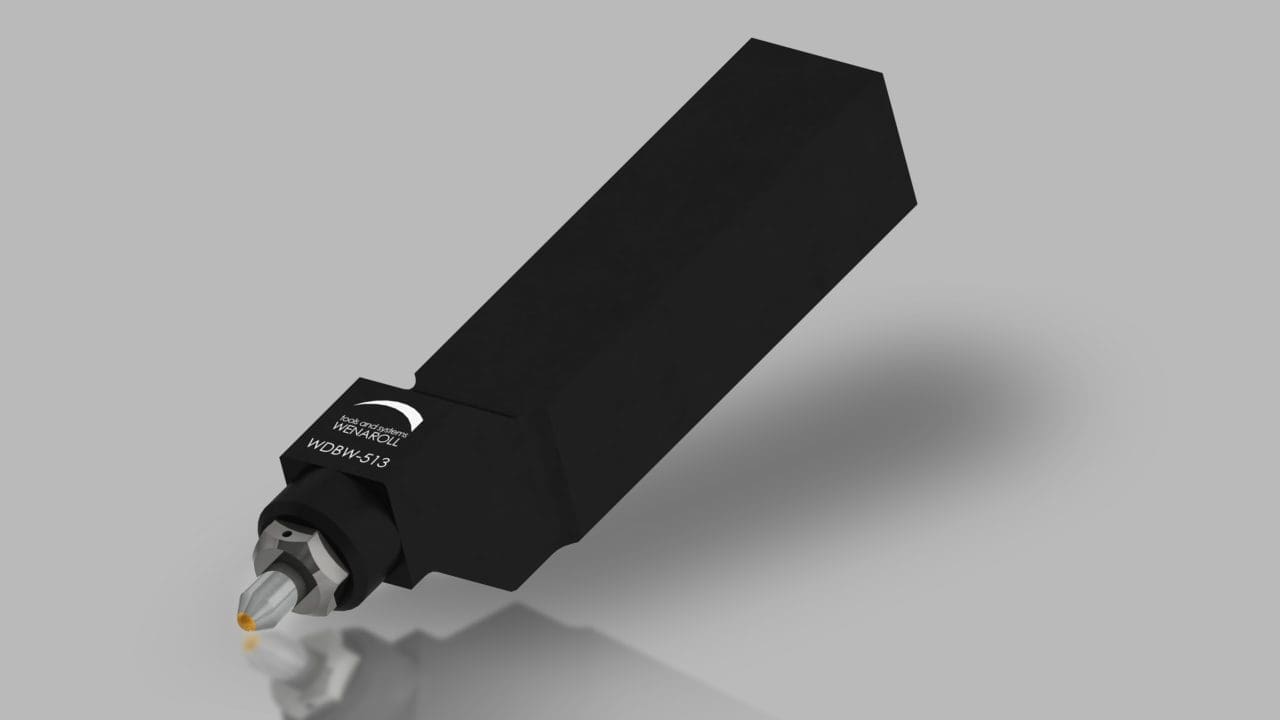

Wenaroll roller burnishing tools type WIW consist of a tool body and a roller burnishing head. The tool body has a mechanism for precise diameter adjustment.

Cage, rollers and cone are wear parts and are easily changeable. The tool shank can be chosen freely by the customer and is available as cylindrical and morse taper by default. If you need any other tool shank, feel free to contact us and we will create a tool according to your needs.

The standard burnishing depth is 50 mm, if this should not suffice you can order the longer version with up to 100 mm. If this still is not enough, please feel free to contact us and we will work on a solution.

Please keep in mind that this only applies to tools with diameters smaller than 35 mm. All tools larger than that are only limited be the length of the tool and can be adapted with a special bar to increase the maximum processing depth. If you have any questions, feel free to contact us.

Process

All metal materials up to a yield strength of 1400 N/mm² and a maximum hardness of 45 HRC can be processed with our tool. During the process either the work piece or the tool can rotate. The tools can be used on conventional or CNC machines.

The circumferential speed of the tools can go up to 250 m/min the feed varies around 0,1 mm/R and 0,3 mm/R per roller.

Data sheet - Technology Guide

All dimensions in mm. EV: Self-feeding | MV: Machine-feeding