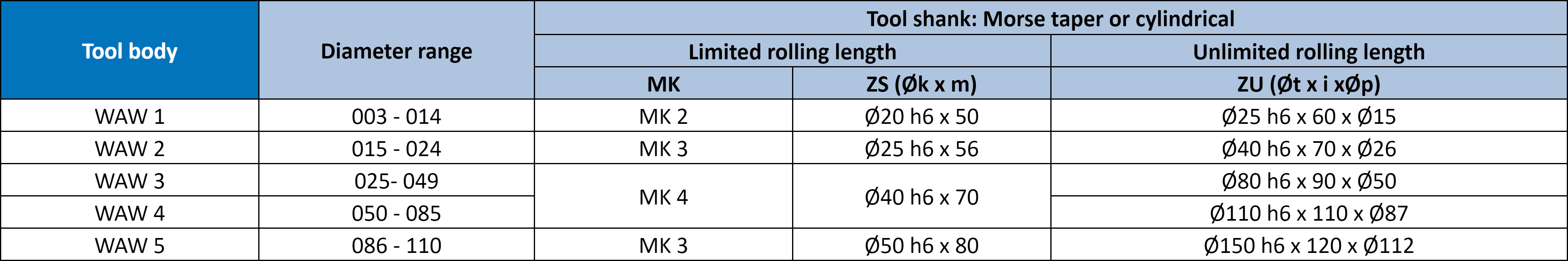

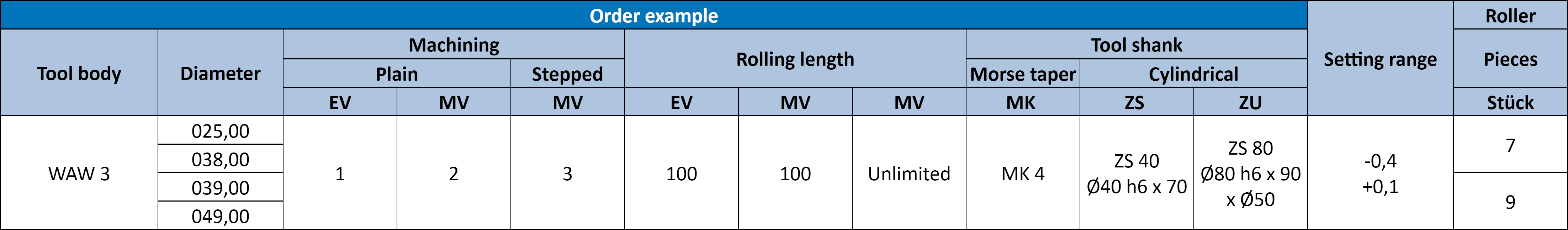

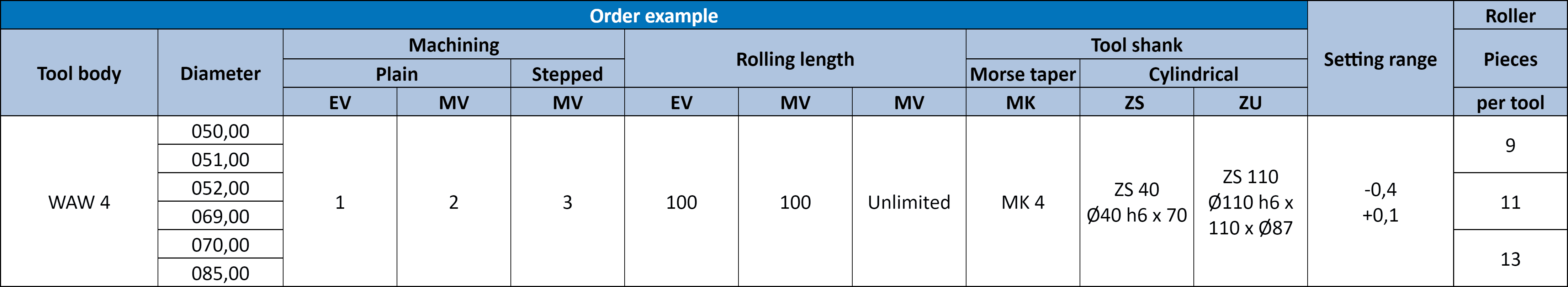

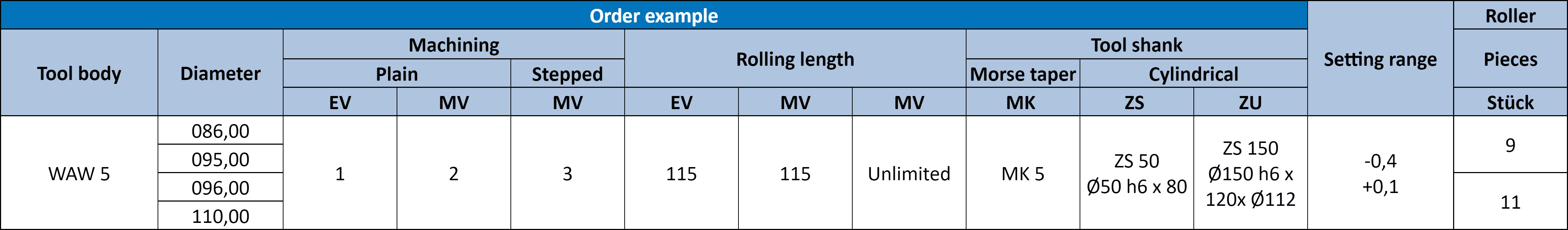

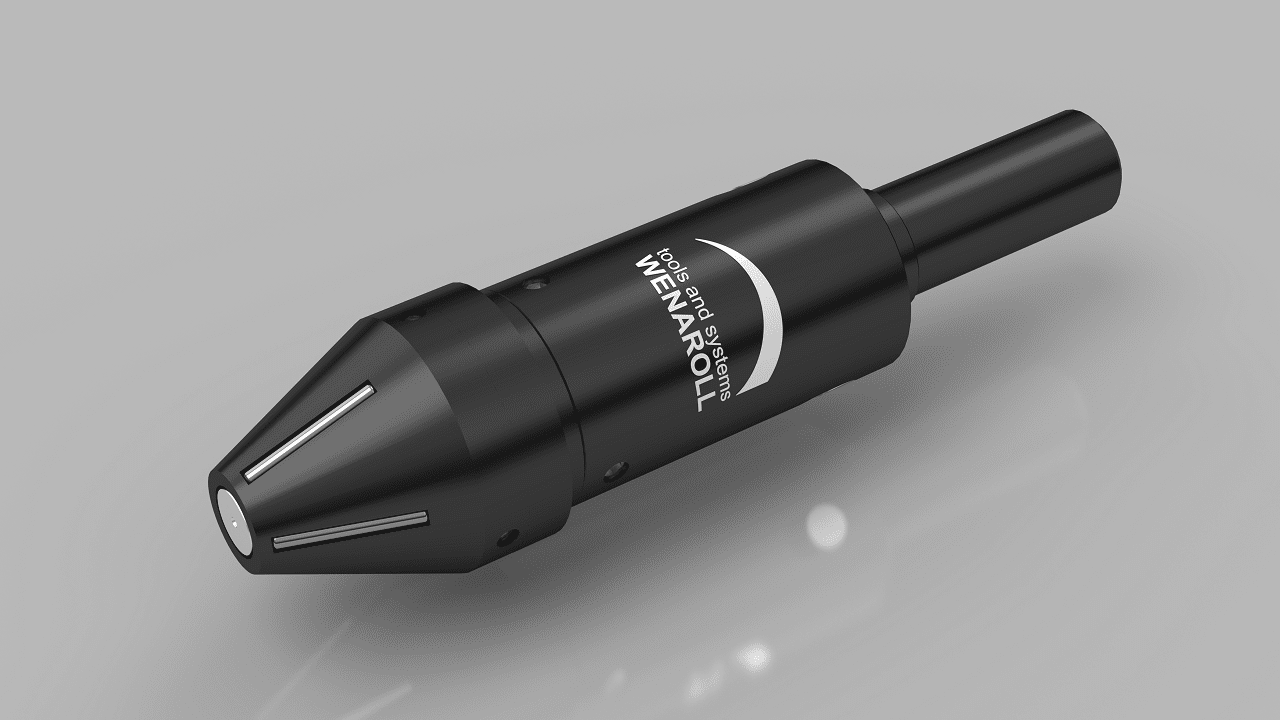

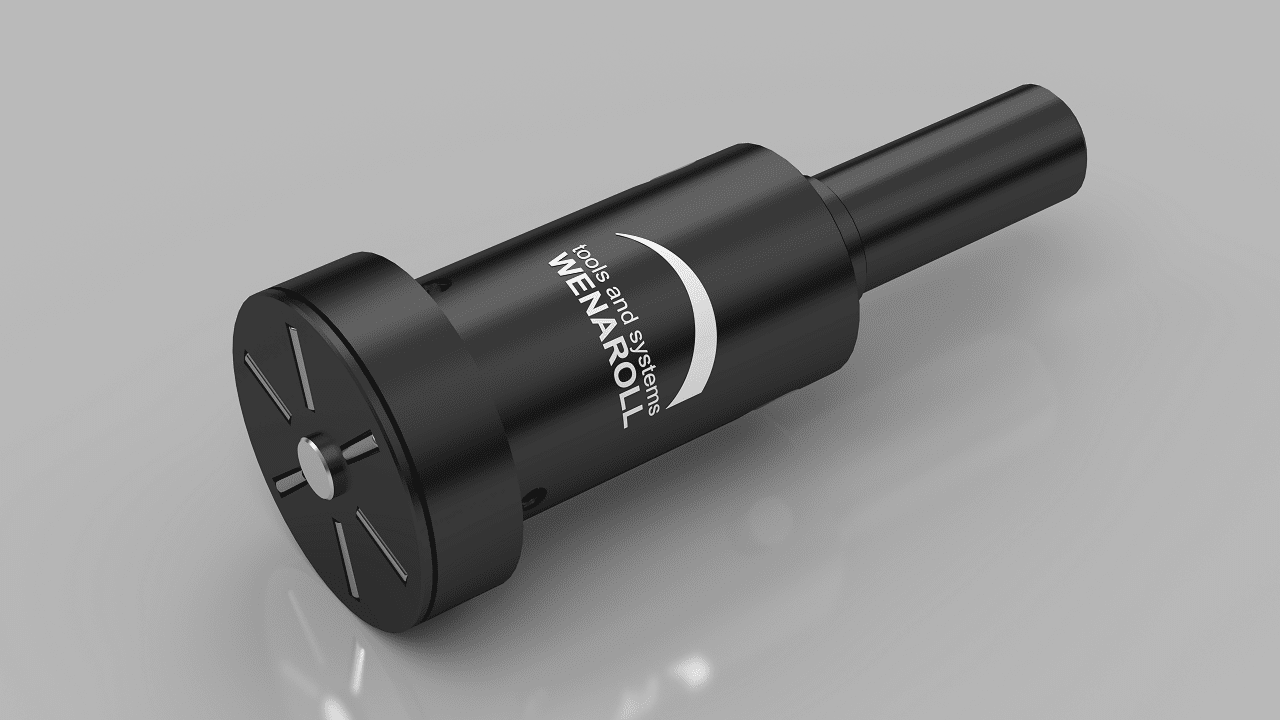

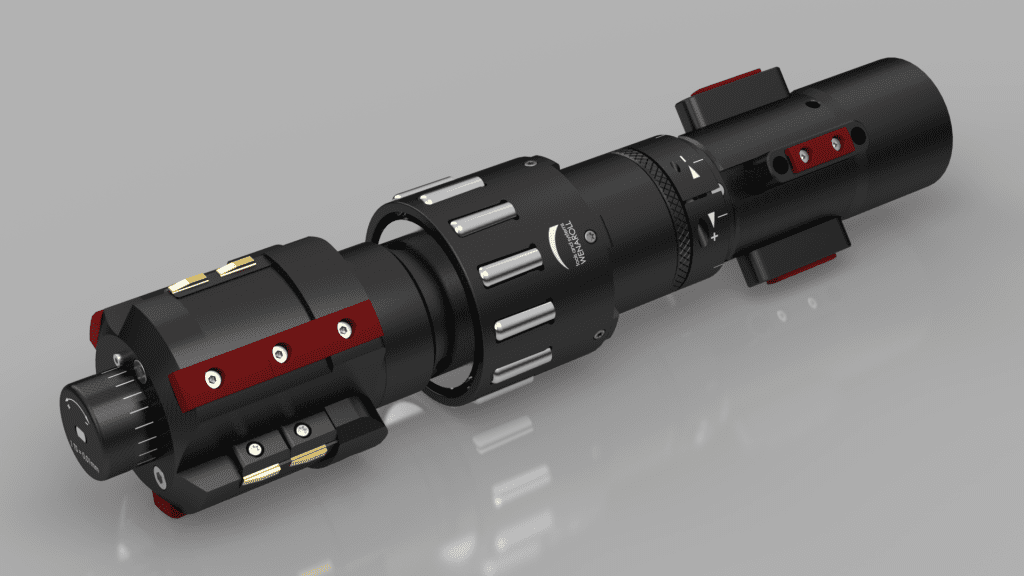

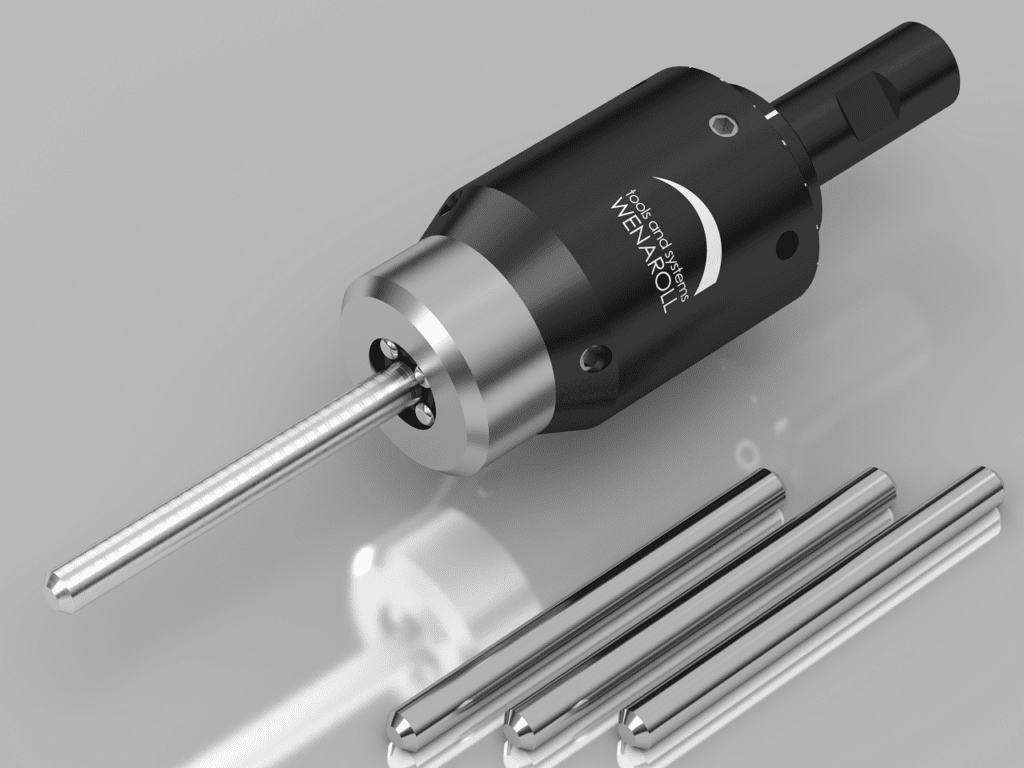

Type WAW Ø3 – Ø85 mm

- Surfaces with a quality of Rz < 1 µm can be produced quickly

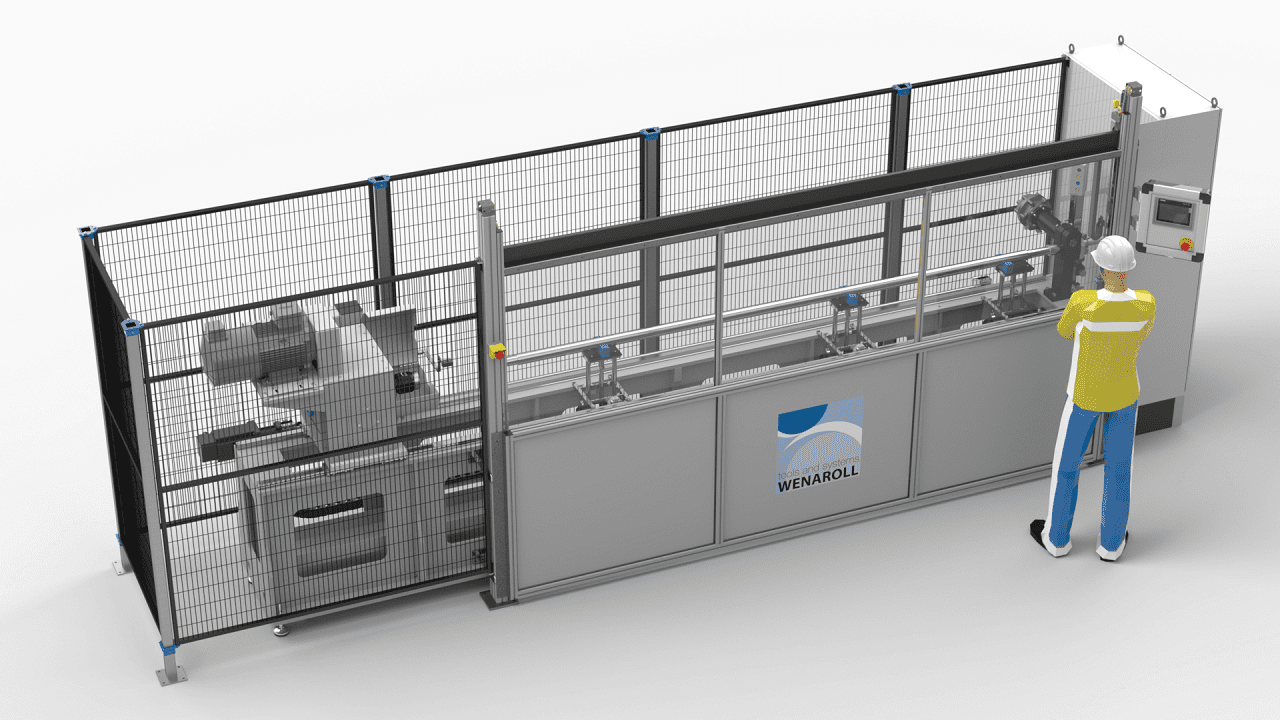

- Can be used on all rotary processing machines

- Long service life of the tool and the spare parts

- Chipless and almost noiseless machining

- Quick replacement of the wearing parts

- Requires little cooling and can be operated with any cooling system

- Quickly adjustable

- Spring-released retraction

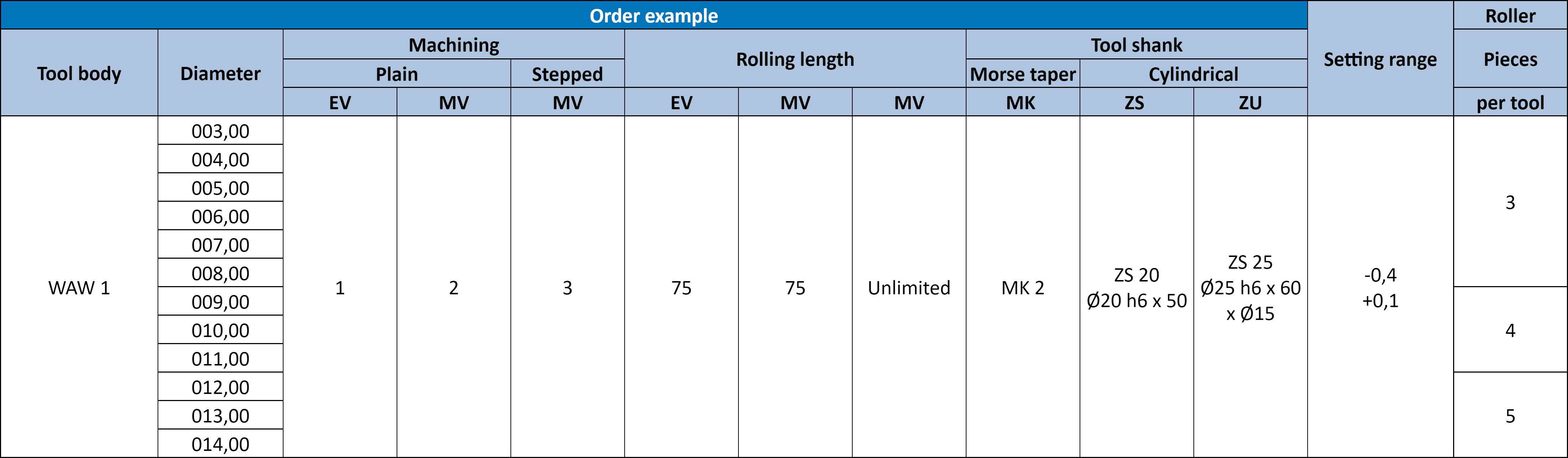

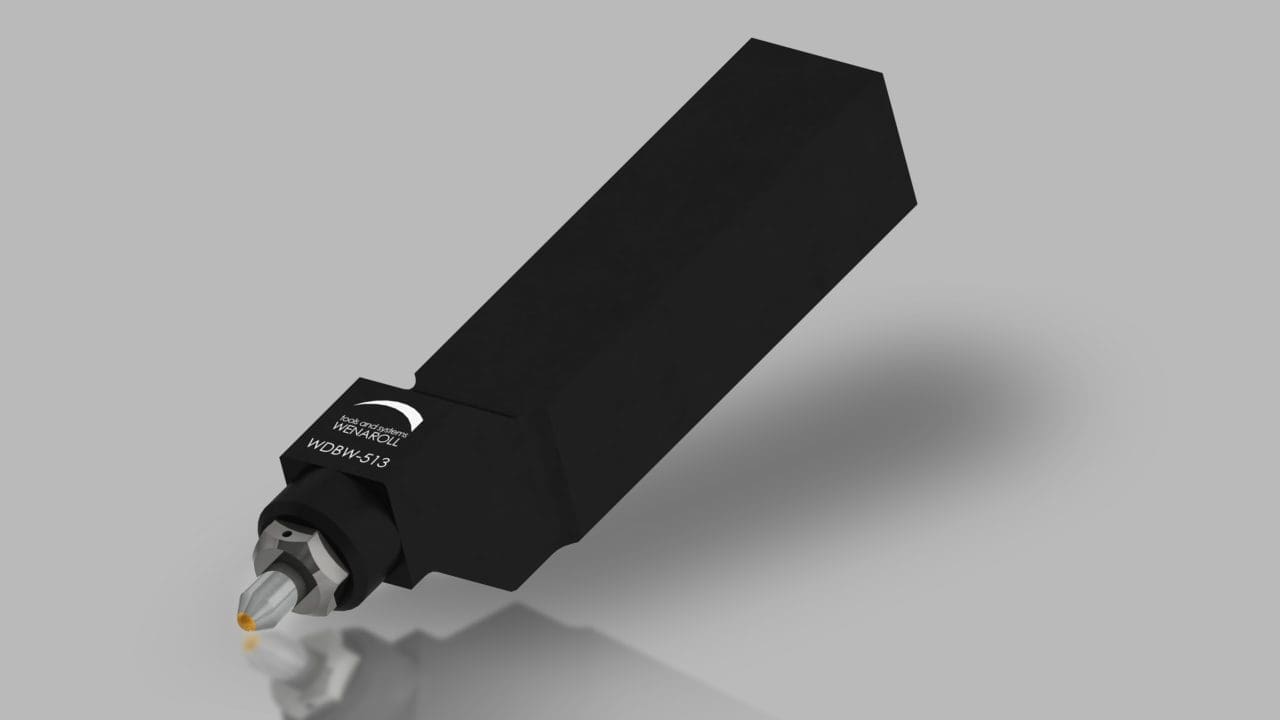

WAW1.-005,00-3-75-ZS20

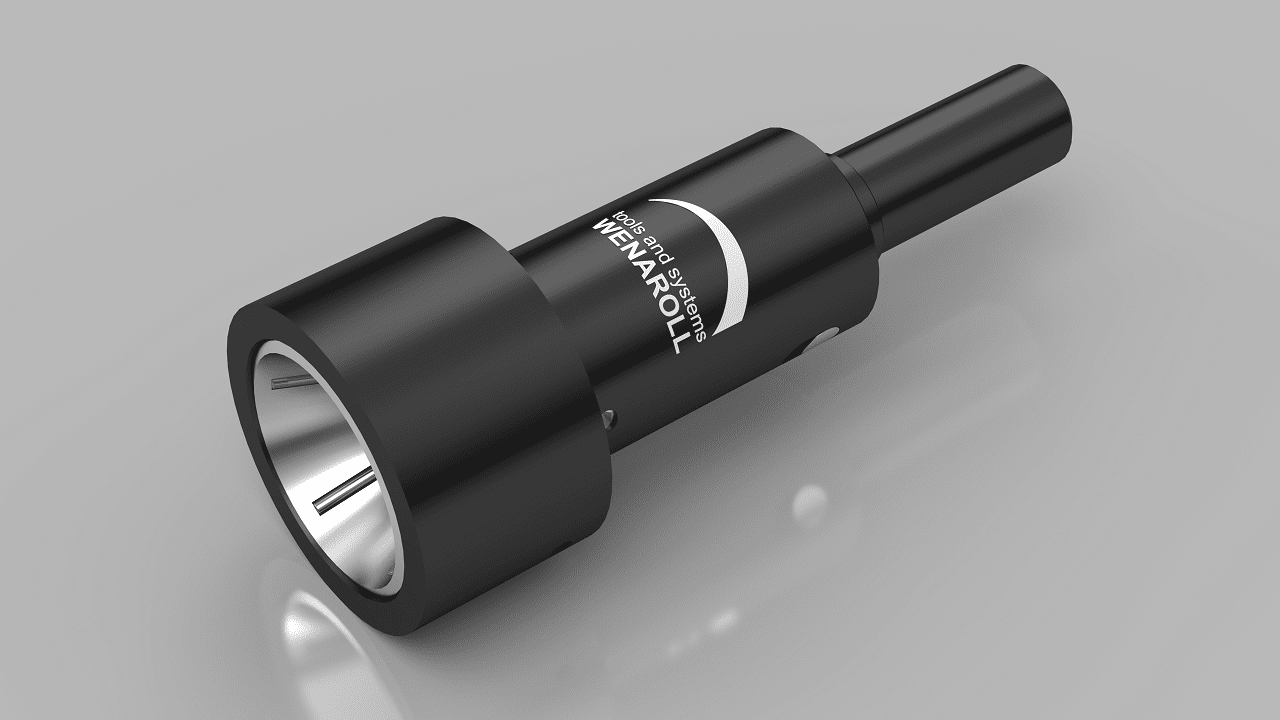

- WIW1.2 | Tool body

- 005,00 | Diameter 5

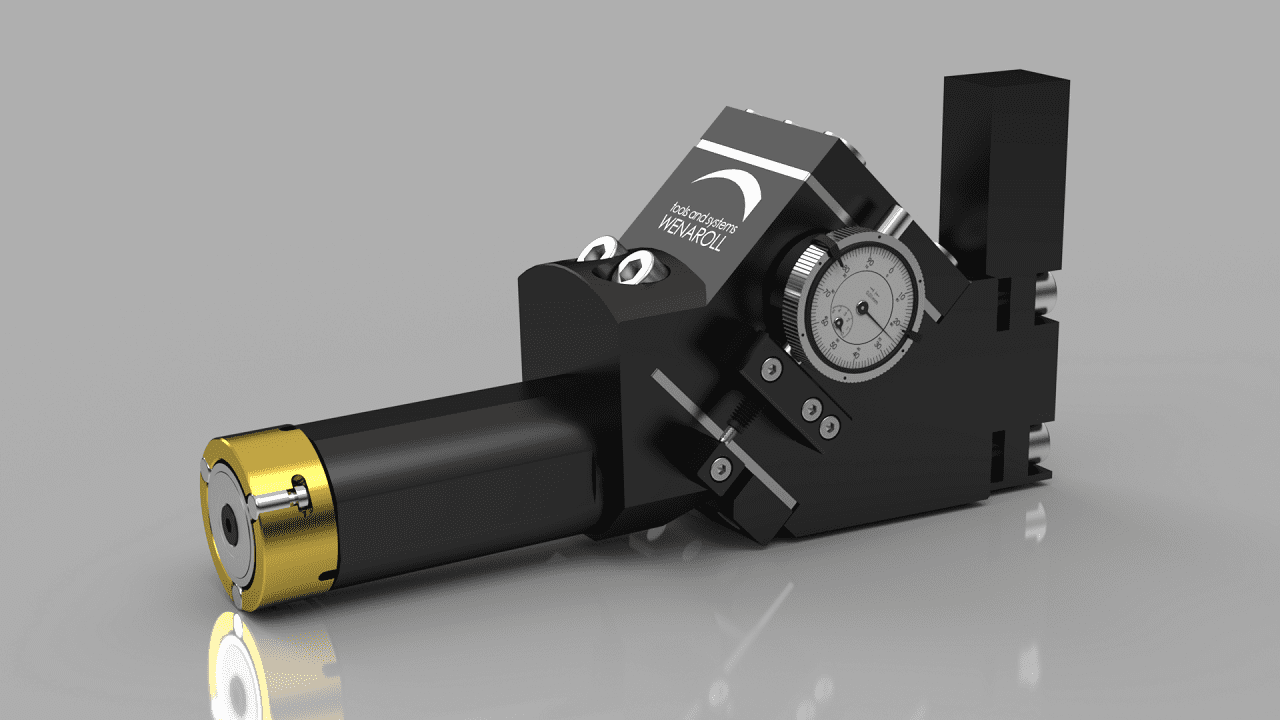

- 3 | Machining of stepped workpieces with machine feeding

- 75 | Max. Rolling length 75mm

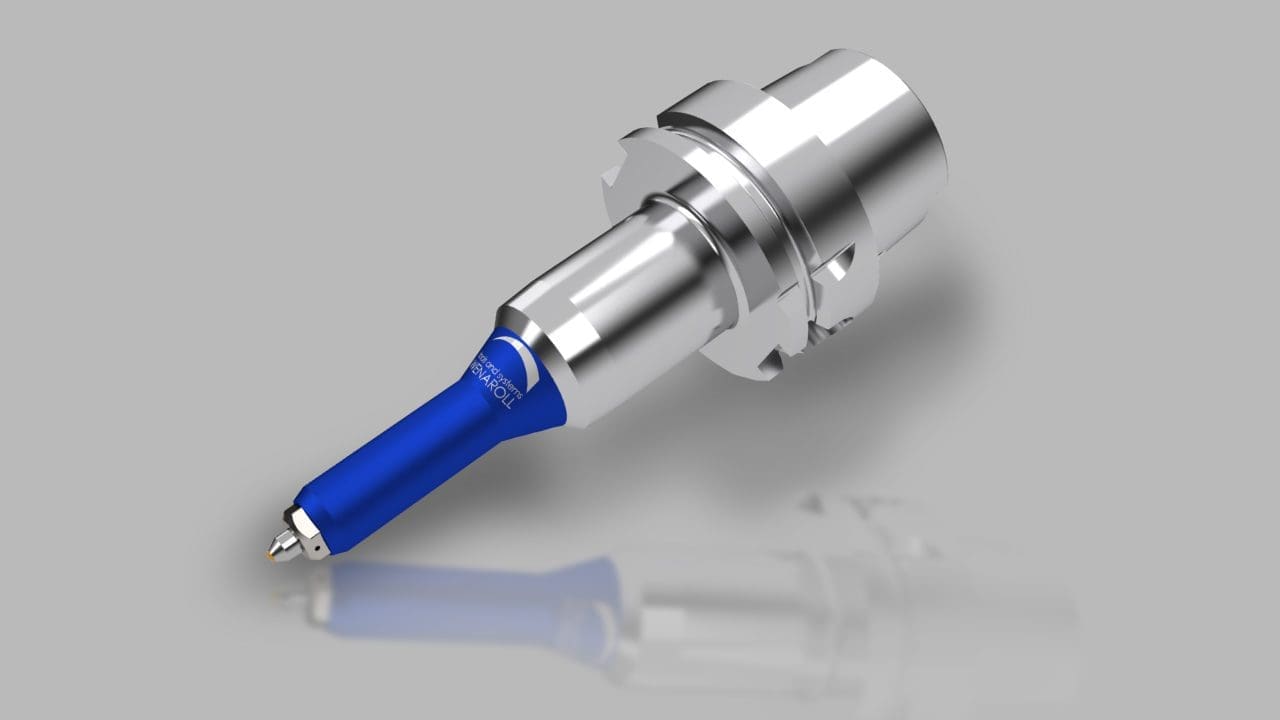

- ZS20 | Cylindrical shank Ø20 h6 x 50

Description

WENAROLL WAW roller burnishing tools for cylindrical shafts produce fits with only one infeed. To meet your precision requirements, the machining diameter of our tools can be adjusted in the µm range. Type WAW tools are offered for both plain and stepped workpieces. Plain workpieces can be machined with self-feeding and machine-feeding. Stepped workpieces can only be machined with machine-feeding.

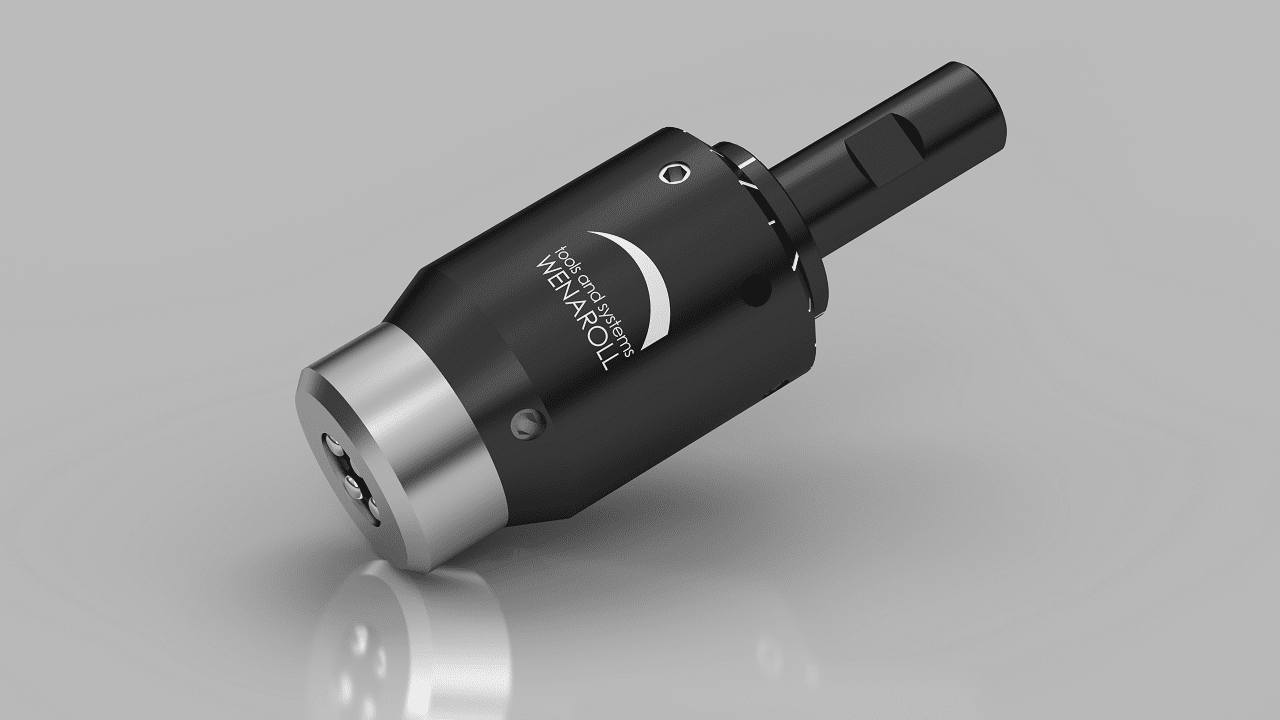

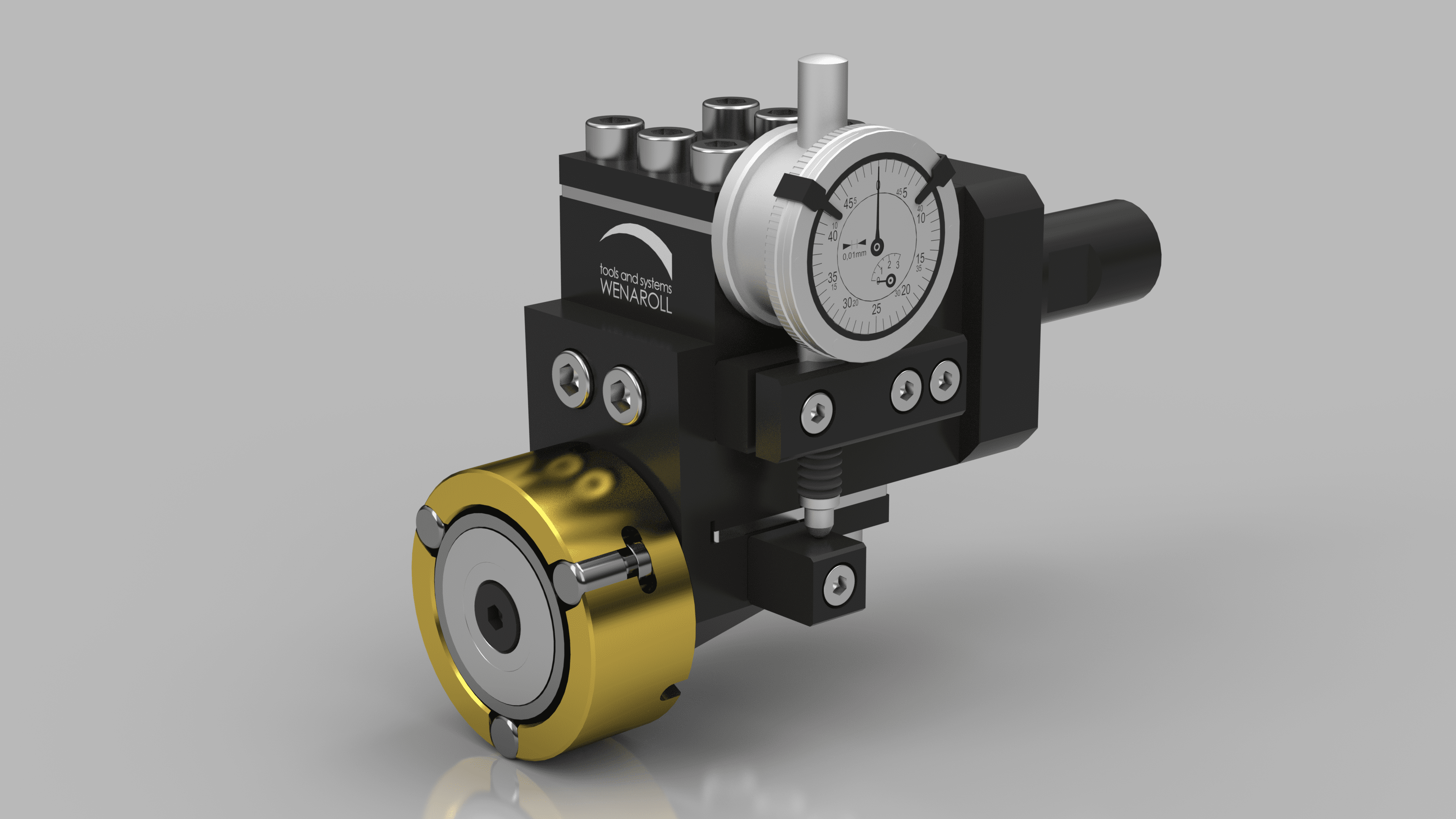

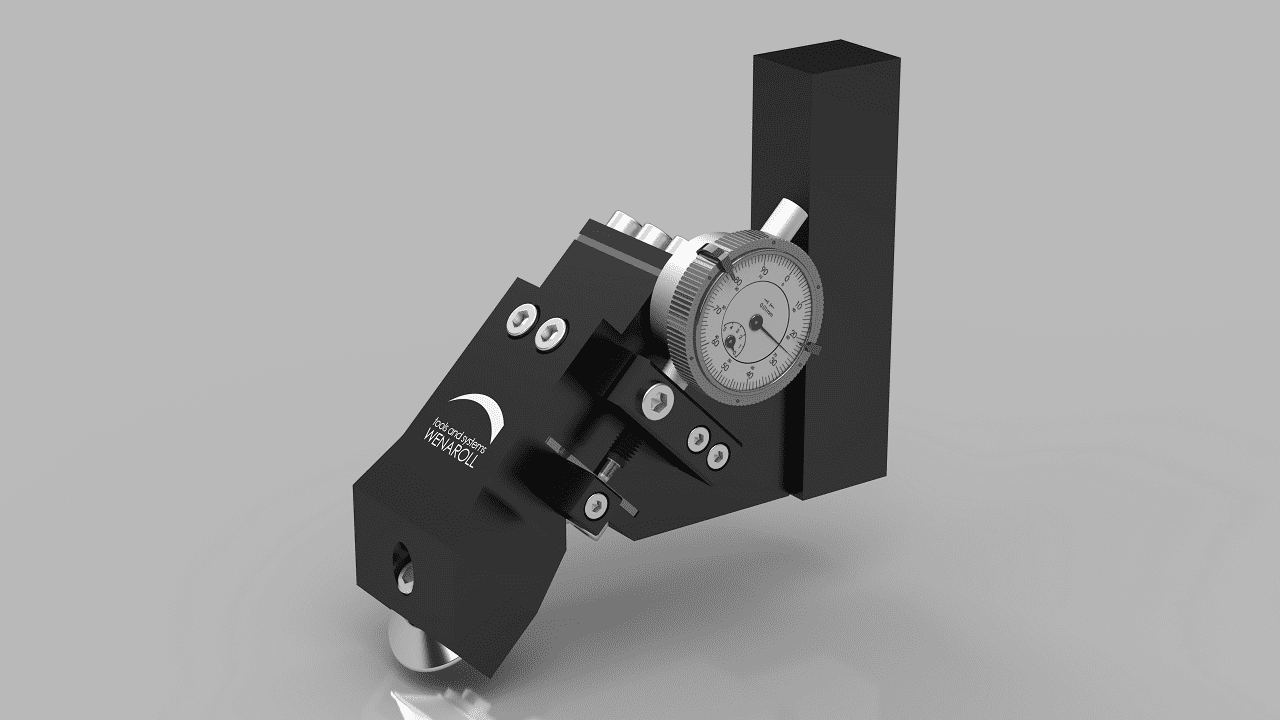

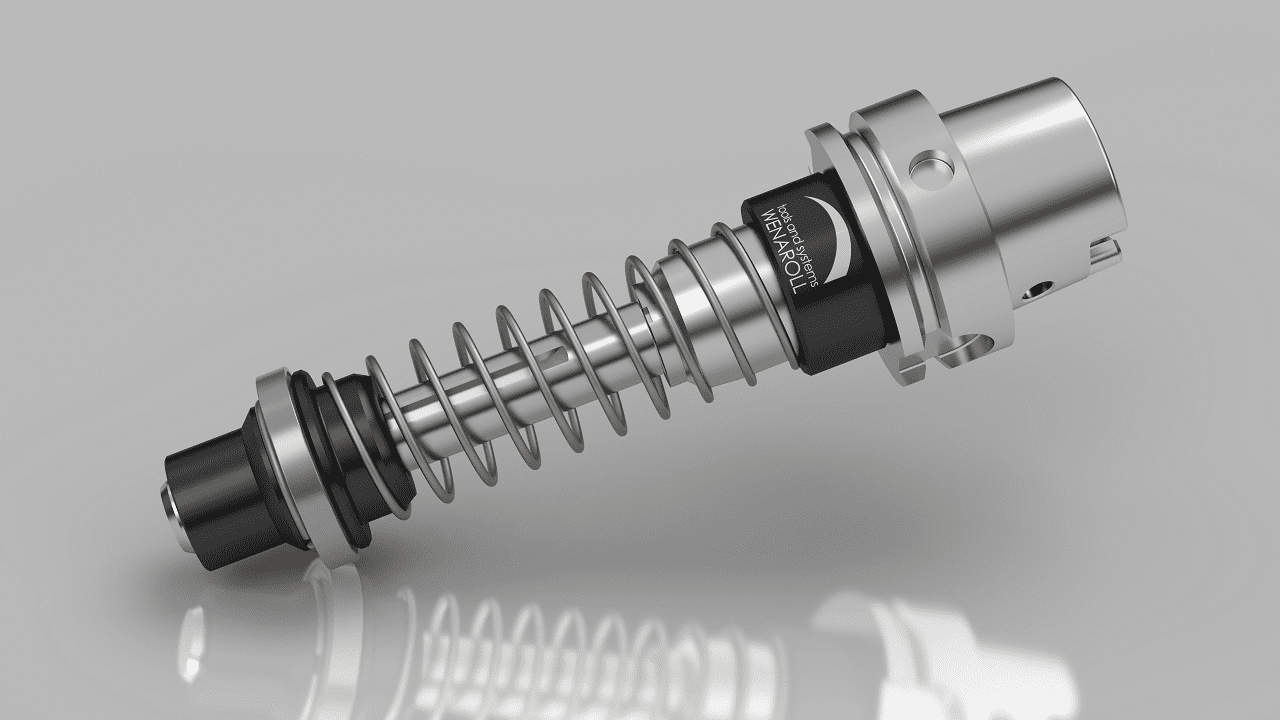

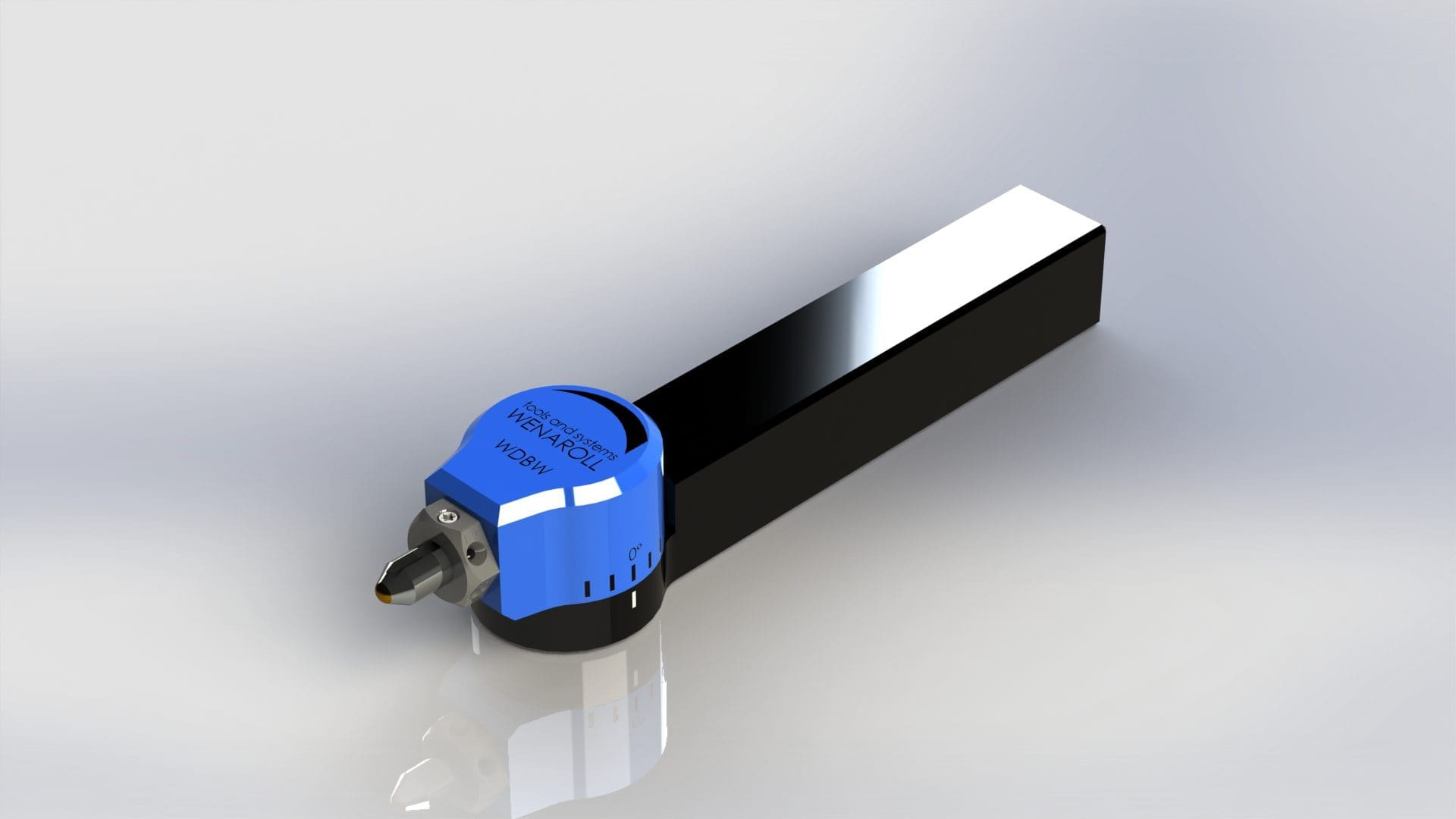

Tool structure

The compact design of our WAW type burnishing tools consists of a tool body and a burnishing head. The mechanism for precise adjustment of the processing diameter is located in the tool body. Cage, rollers and cone are wearing parts and can be replaced without any problems. As interface to the machine, we offer cylindrical tool shanks, Morse tapers or other special designs on request. The machining depth of the tools in the standard version is between 75mm – 115mm, if this is not sufficient, we can offer cylindrical holders with clearance.

Process

All metallic materials with a tensile strength of up to 1400 N/mm² and a maximum hardness of 45 HRC can be machined with our tools. Either the workpiece or the tool can rotate. The tools can be used on conventional CNC machines as well as on machining centers, lathes and milling machines. The circumferential speed of the tools can be up to 250 m/min, the feed rate is between 0.1 mm/rev and 0.3 mm/rev per roller.

Data sheet - Technology Guide

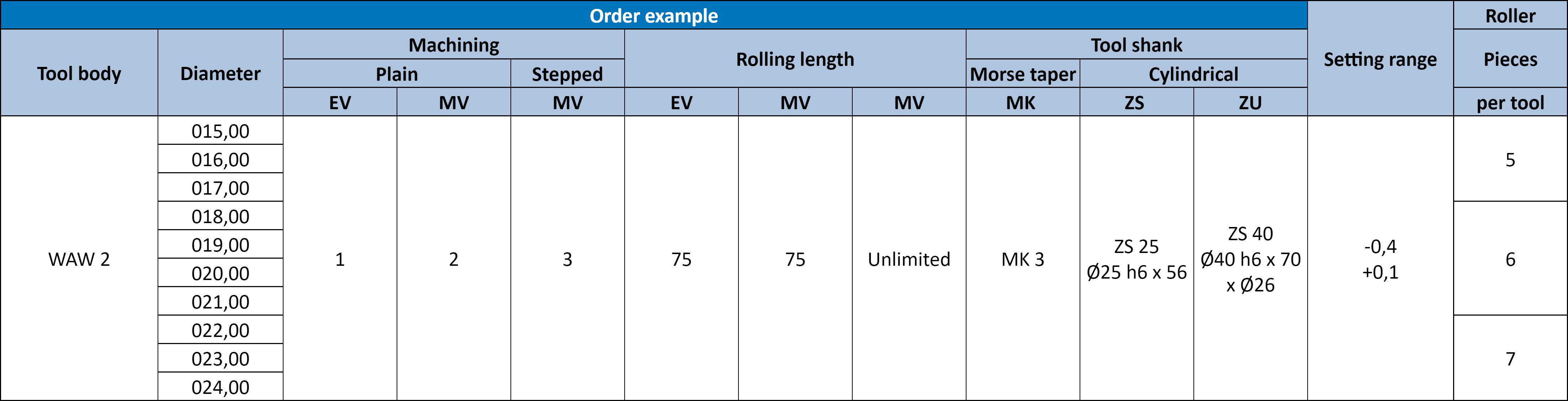

All dimensions in mm. EV: Self-feeding | MV: Machine-feeding