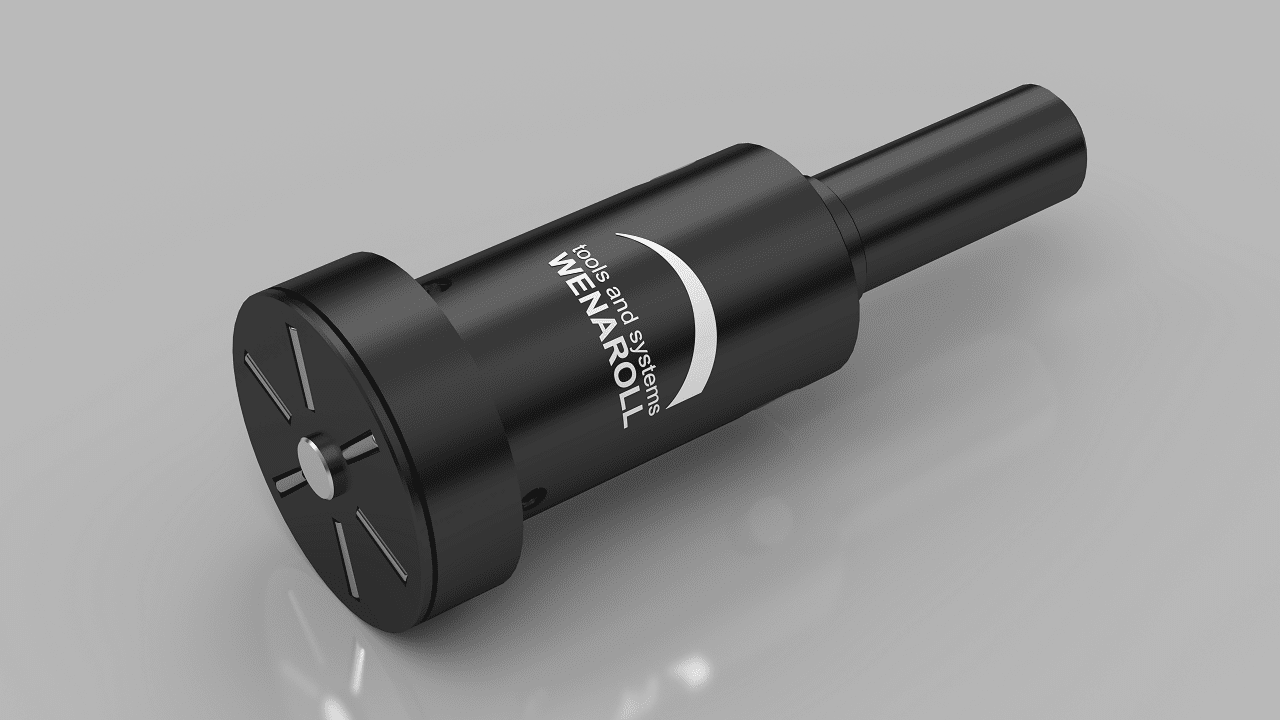

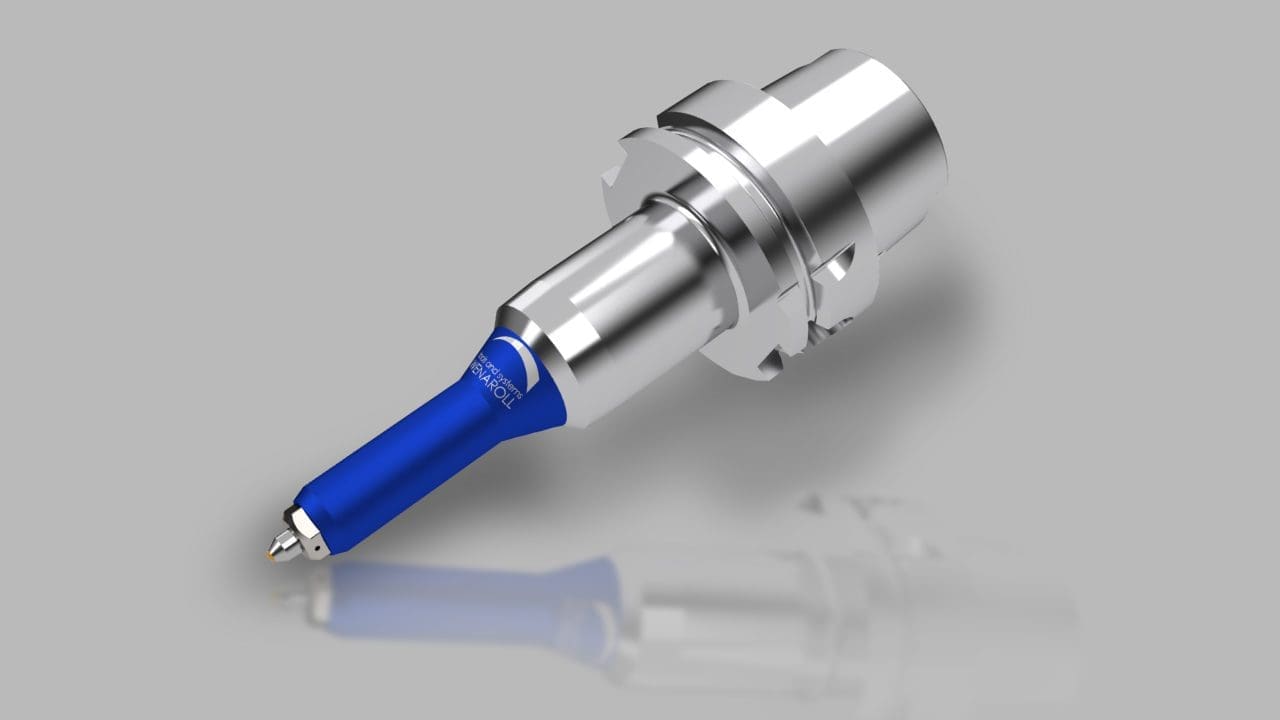

Type WPS

- Up to 90%-time savings compared to honing

- High dimension and form accuracy

- High chip removal capabilities

- Easy handling

- Few wear parts

For further details please contact us.

Description

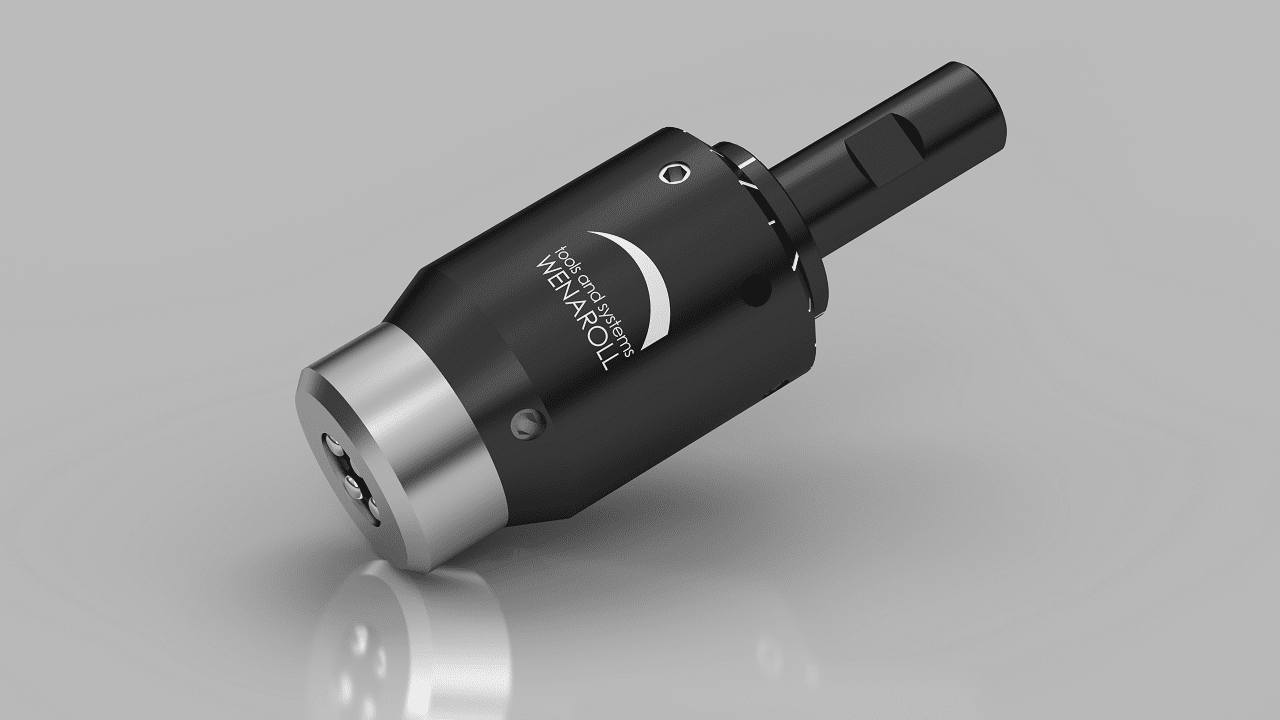

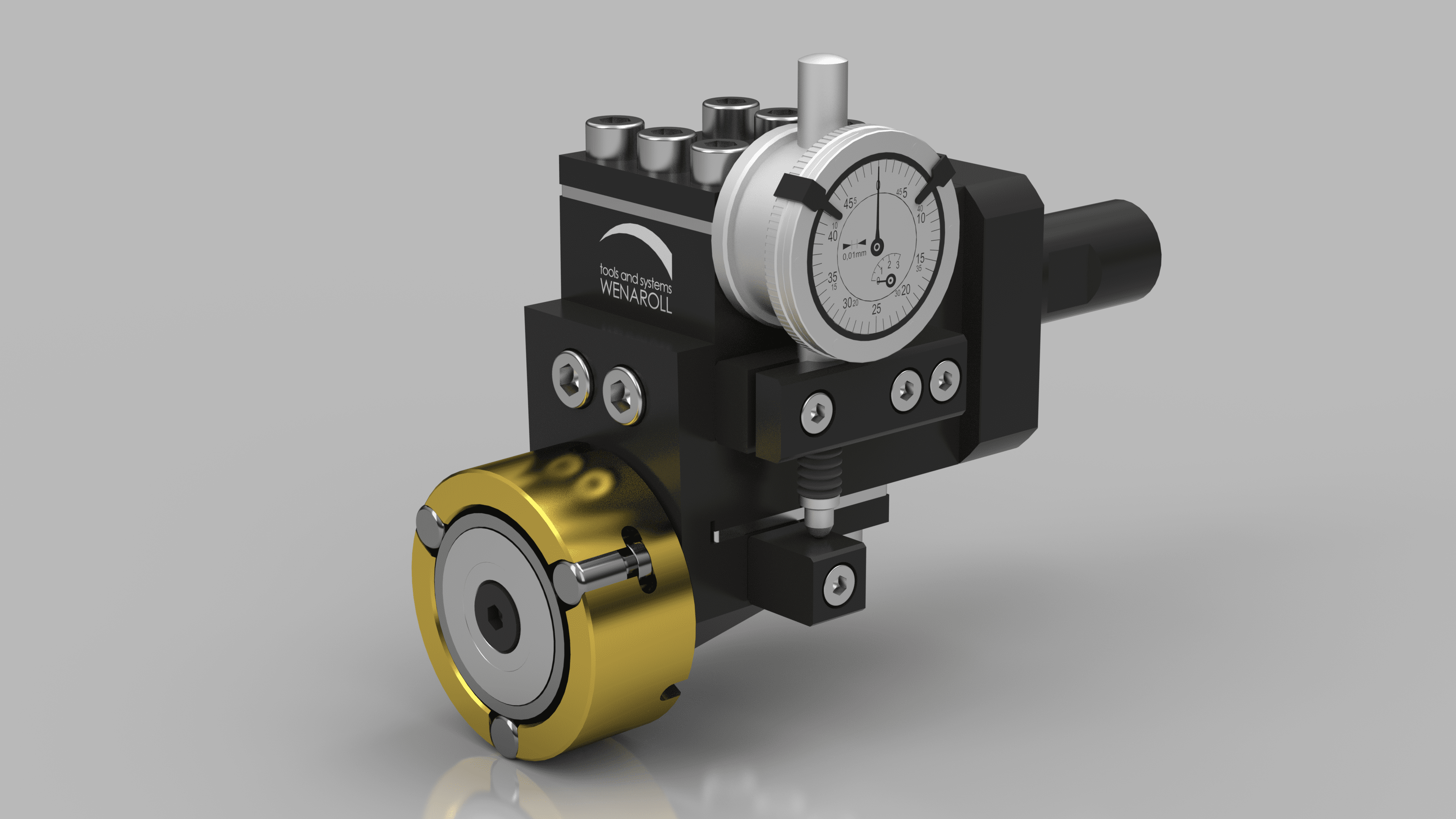

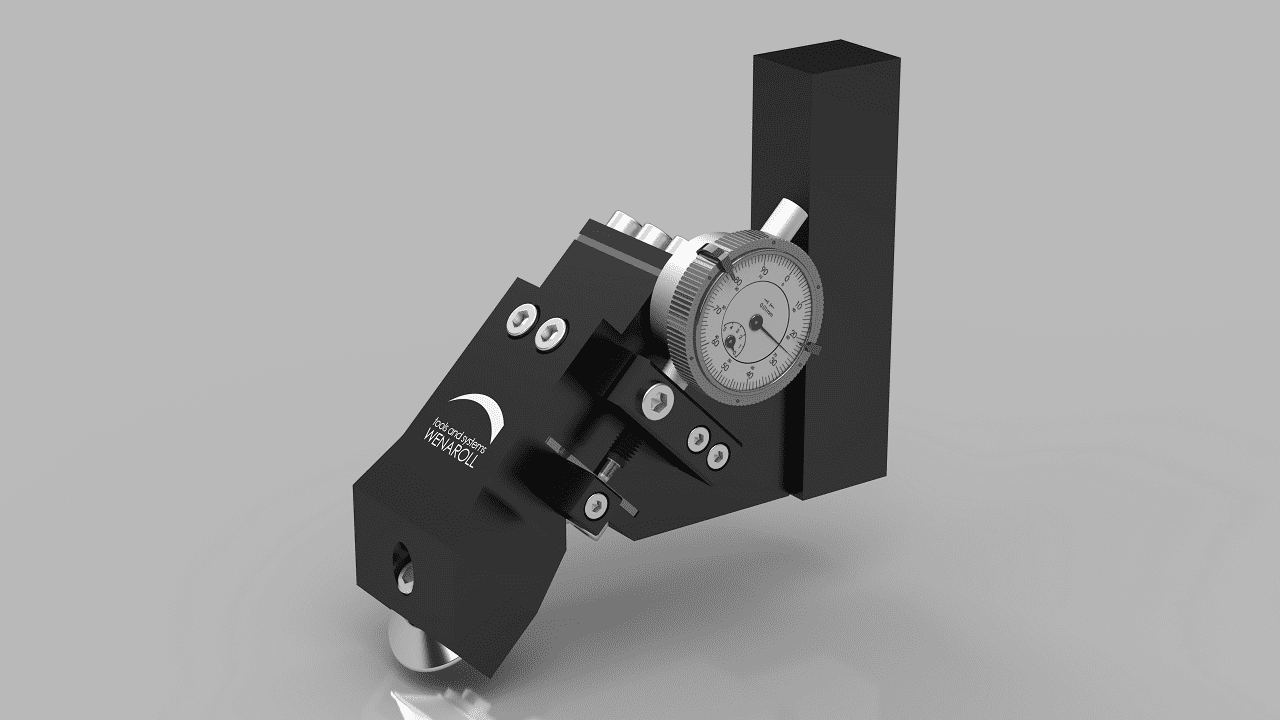

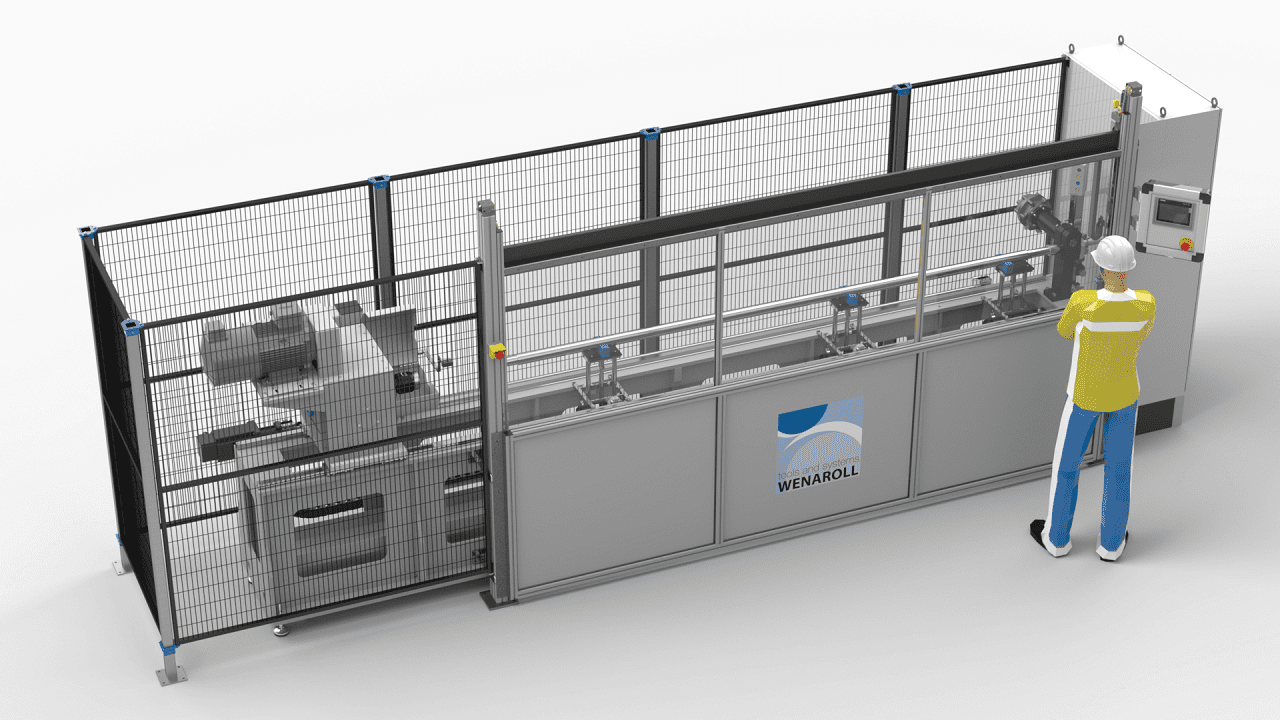

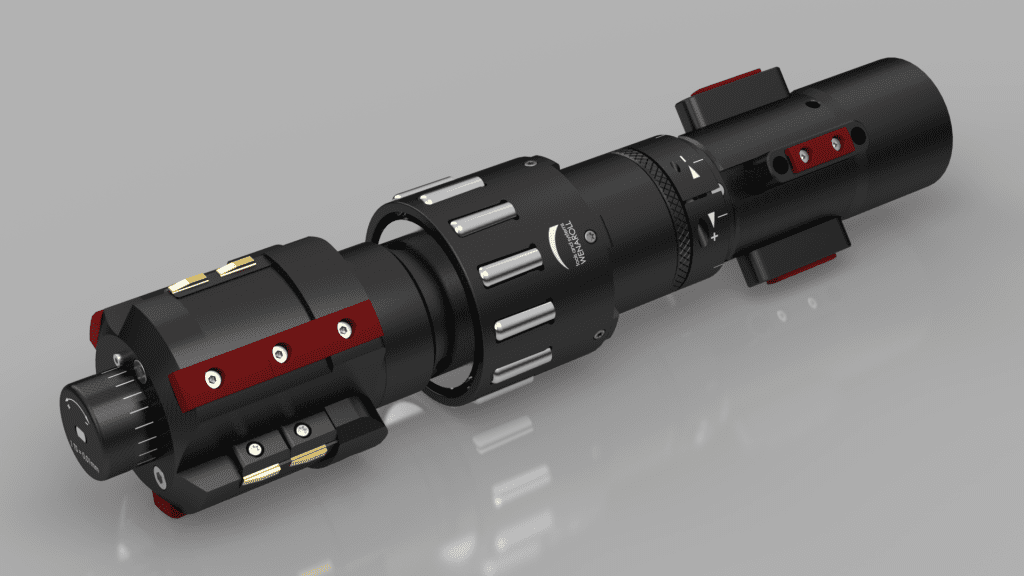

Combined drilling, skiving and roller burnishing tools type WENAROLL Polaris

Choose between two possible tools configurations

• skiving and burnishing (WPS)

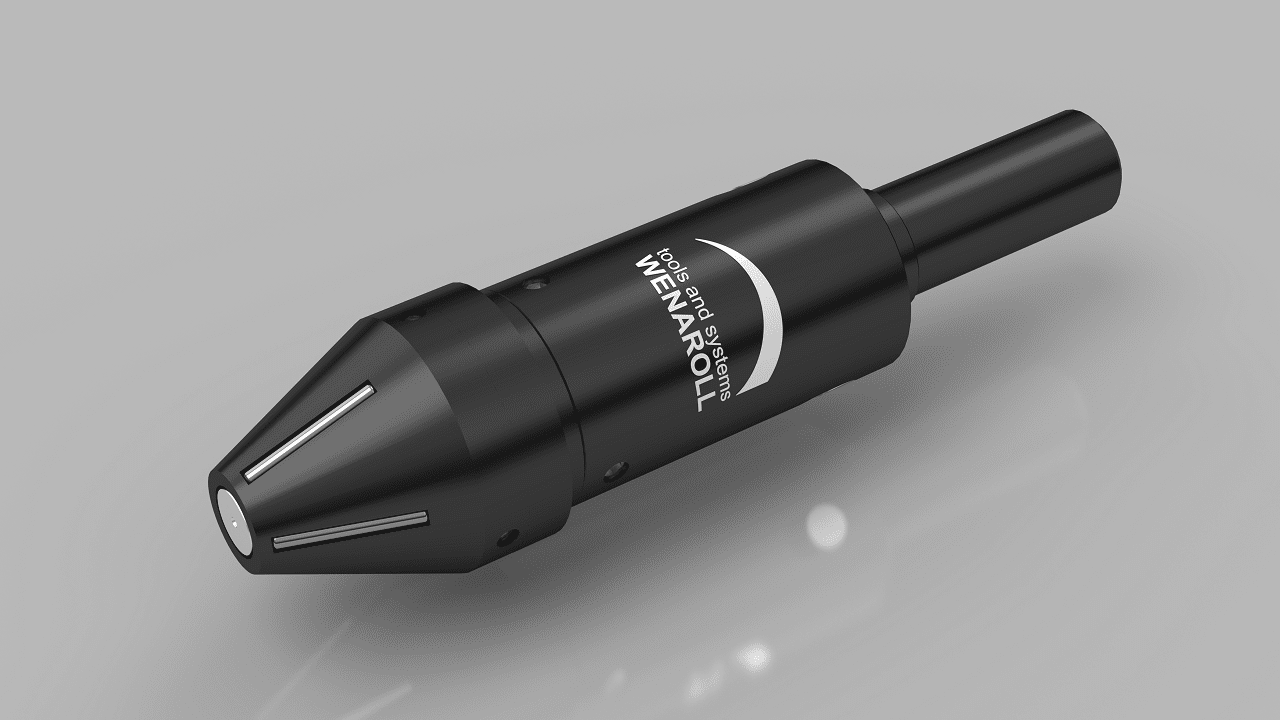

• drilling, skiving, burnishing (WPB)

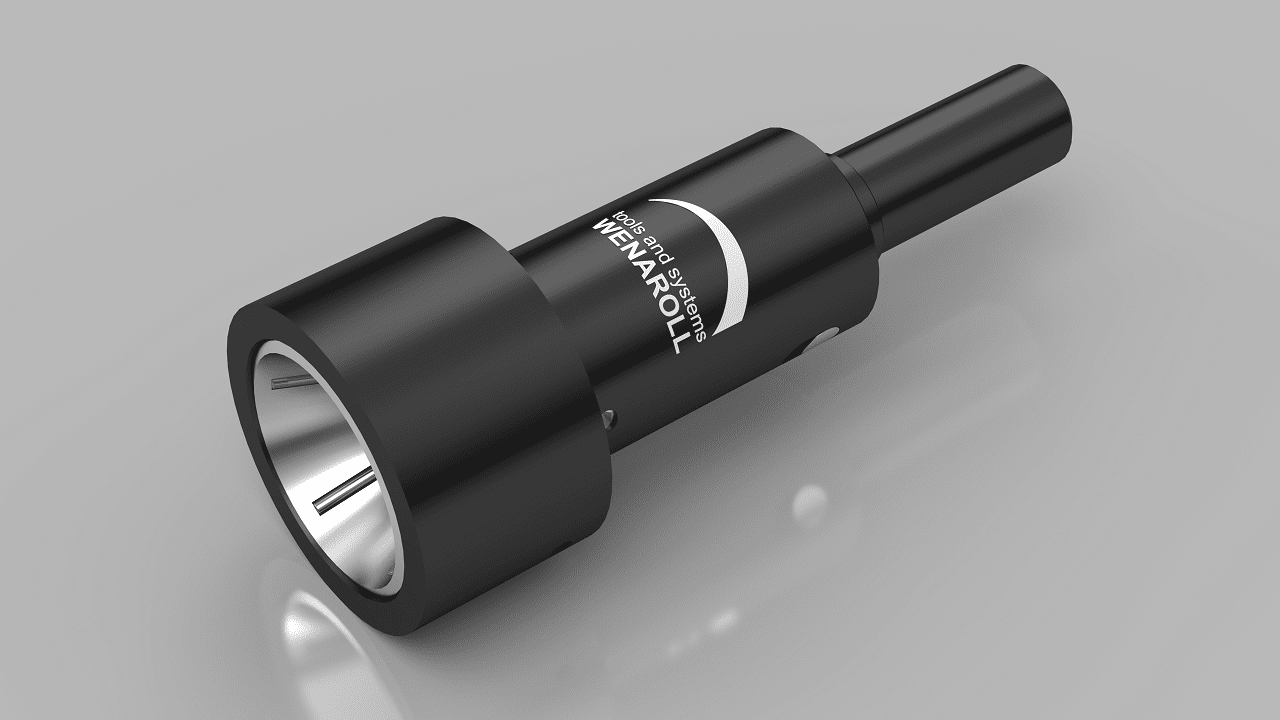

These tools are used for internal finishing of cylinder tubes with a maximum length of up to 12 meters. During the process, you get rid of irregularities in roundness and straightness, that can occur during the manufacturing of these tubes. Furthermore, the tool will produce the required diameter and will provide an optimal surface through the burnishing operation. Wenaroll Polaris tools (WPS) are available starting from diameter 38 mm up to a diameter of 250 mm. Depending on the diameter tubes up to maximum length of 12 meters can be processed. The drilling, skiving and burnishing tools type (WPB) are available starting from diameter 125 mm up to 250 mm, with a maximum length of up to 4 meters.

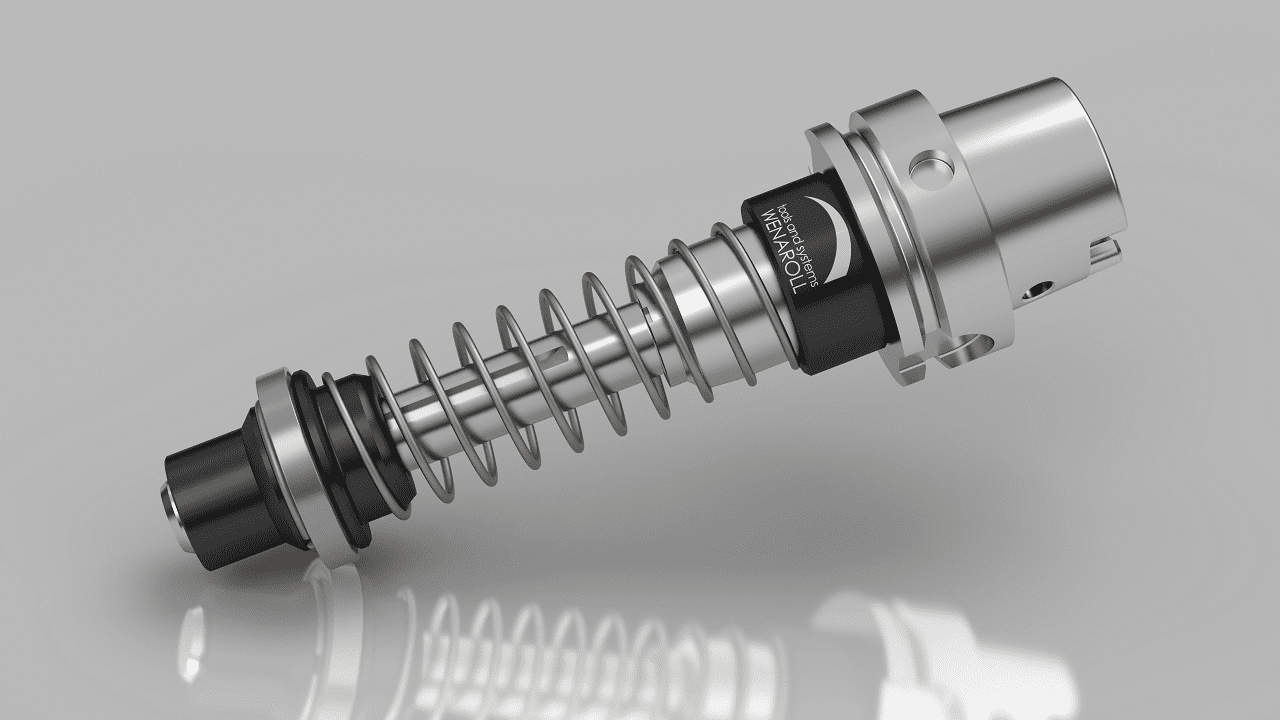

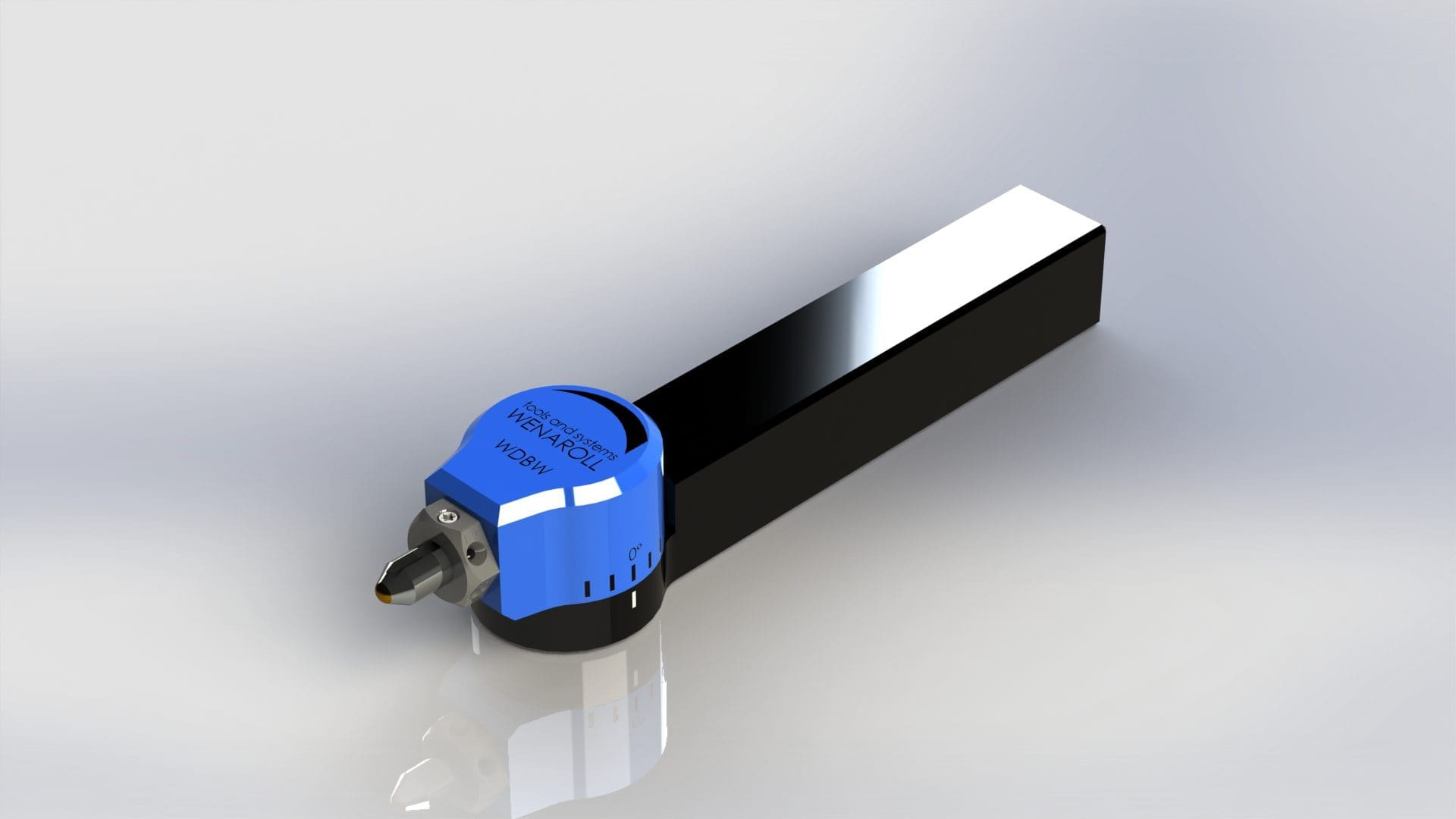

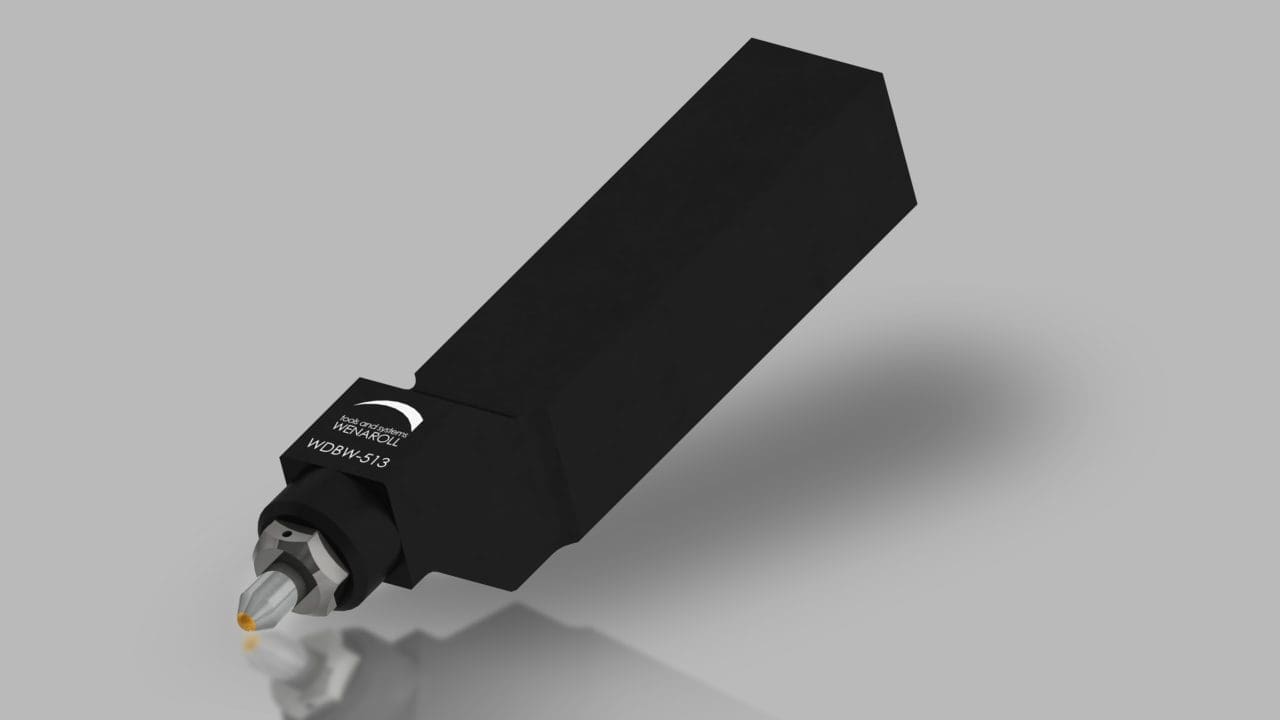

Tool structure

To achieve an optimal surface, the tools are equipped with a rough skiving stage and a finishing stage. All WPB tools will also have a drilling stage, which is used for processing hot rolled tubes that require a large amount of chip removal. Polaris WPS tools can achieve a maximum depth of cut of 2,5 mm, WPB tools can achieve 7 mm in total. For guiding and stability purposes each tool will also feature plastic guiding pads as well as carbide guiding pads (only WPB).

Both tools are equipped with a burnishing stage that will produce the required surface quality after the drilling and skiving operation.

- One tool for multiple operations

- The tool will retract the cutting inserts and the burnishing head during fast traverse to the home position, thus no damage will occur on the finished product

- Environmentally friendly and much quicker process compared to honing

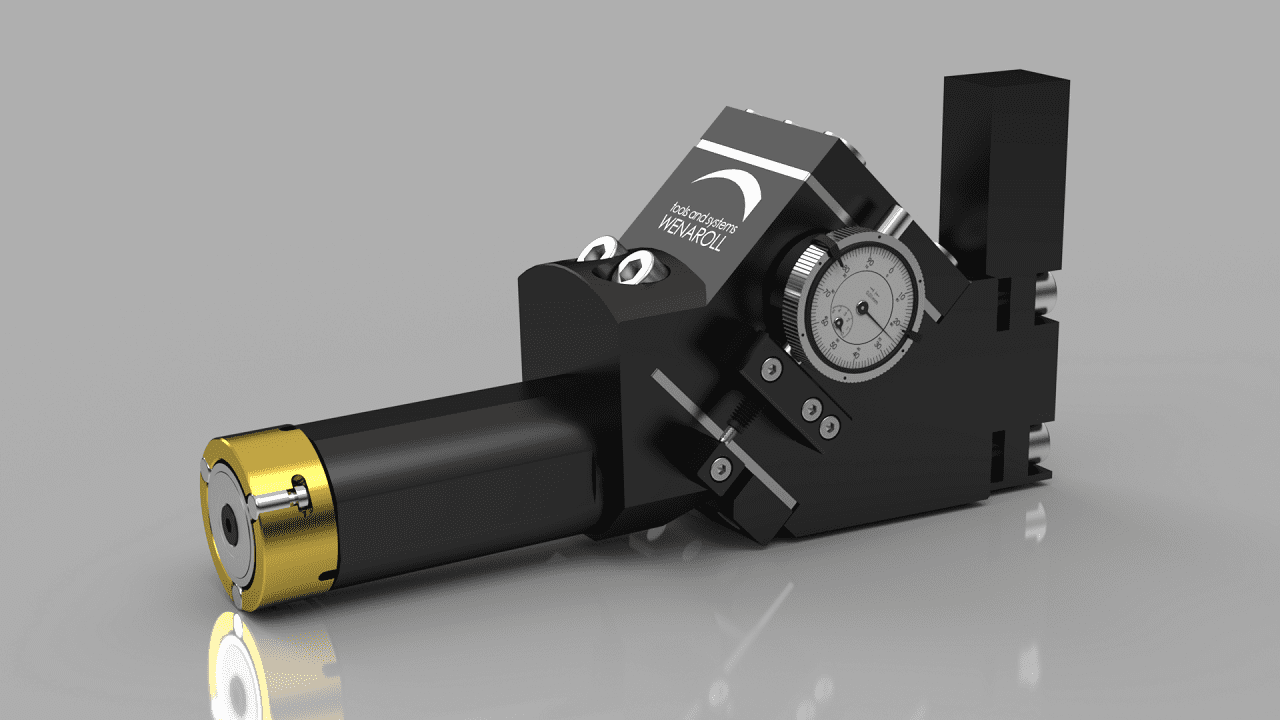

- The tool can be operated (not cooled) with either hydraulic or pneumatic pressure

- The required piston is integrated within the tool