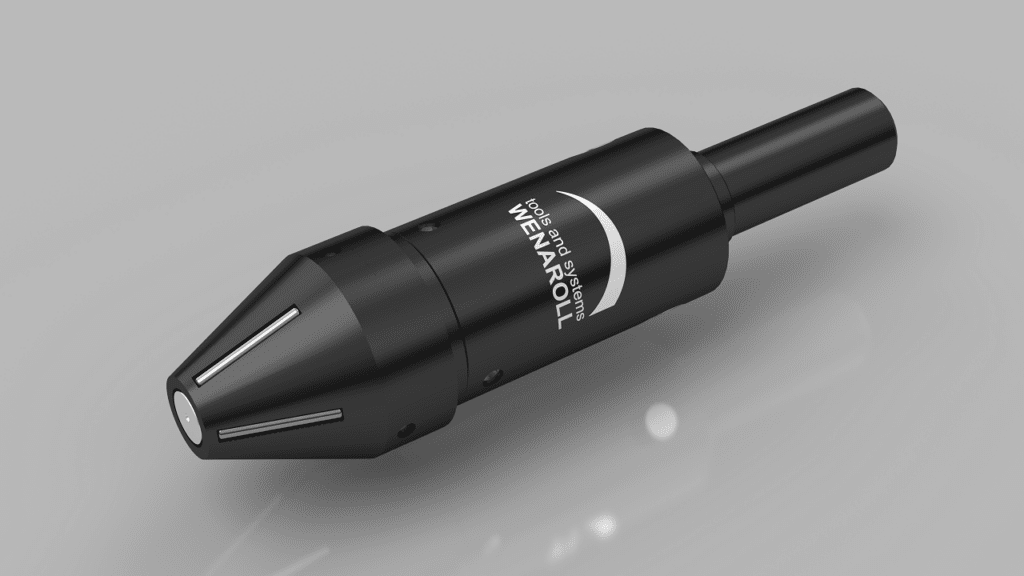

Type WIK

- Surfaces with a quality of Rz < 1 µm can be produced quickly

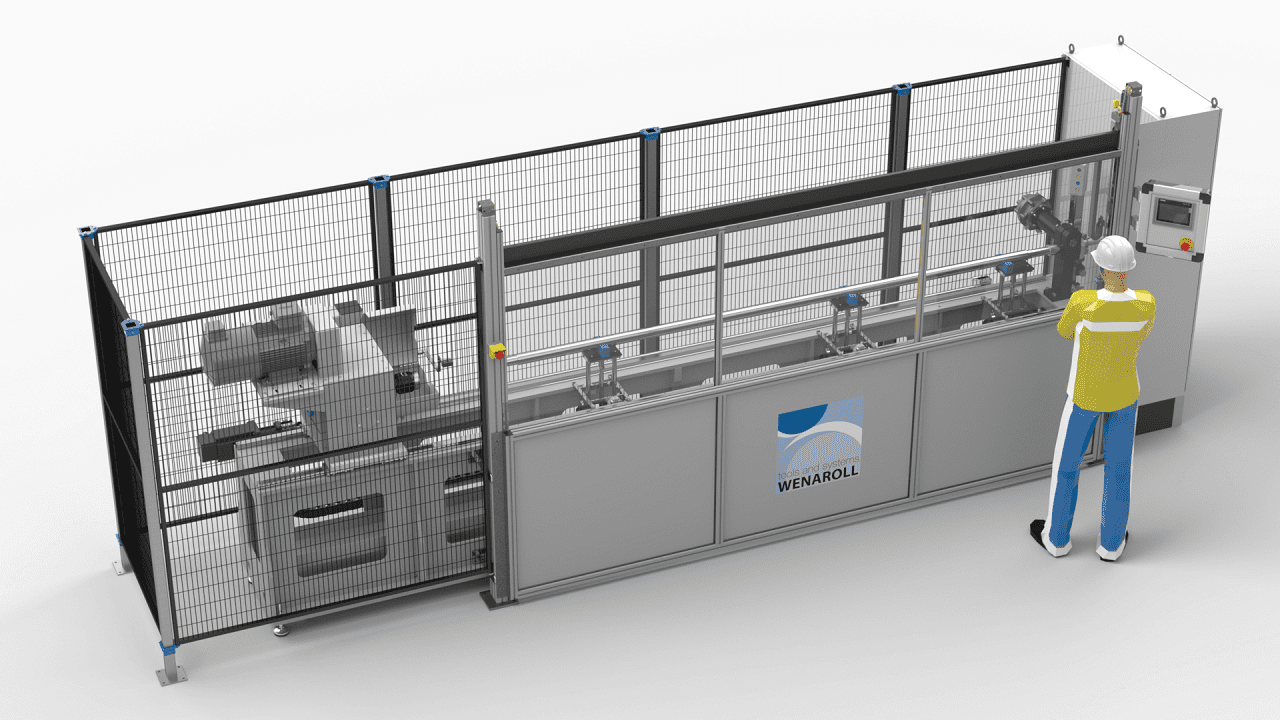

- Can be used on almost every machine that revolves

- Long lifetime for wear parts

- Chipless and quiet process

- Wear parts can be exchanged quickly

- Barely any lubricant / cooling required

- Every tool ist custom-built

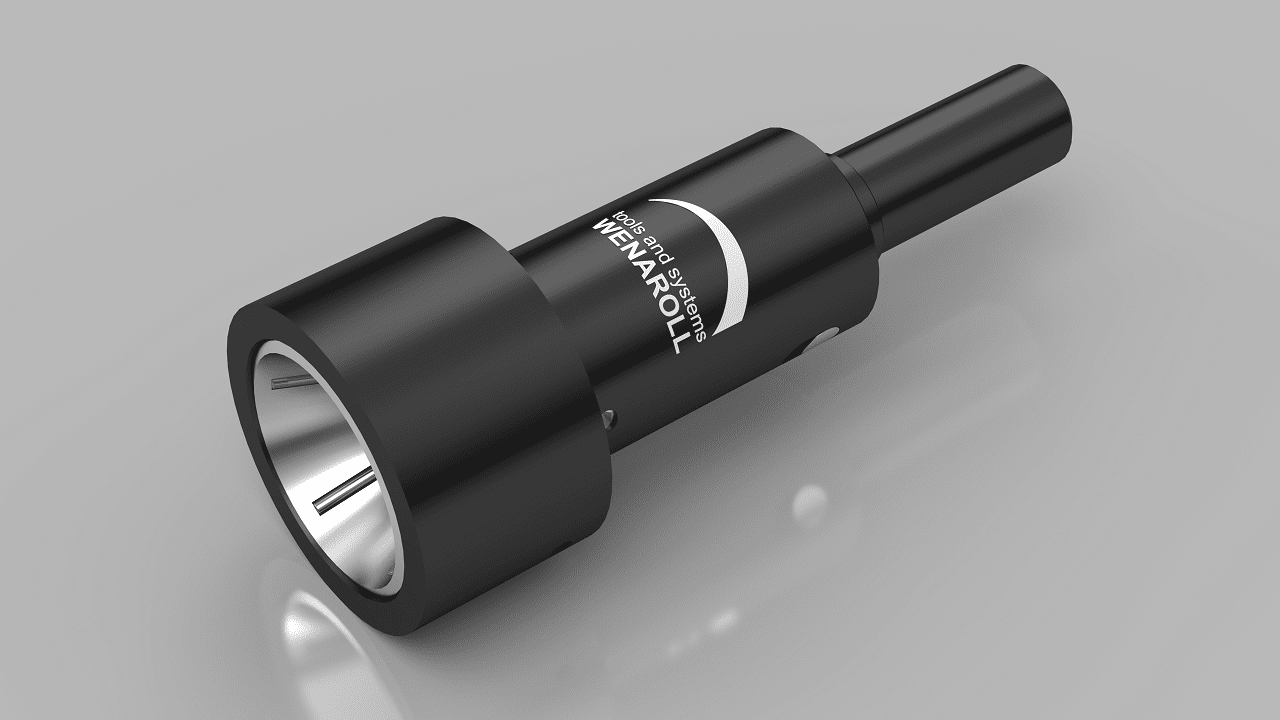

WIK-47,00-33,20-30°-MK3

- WIK | Tool body

- 47,00 | Ø D

- 33,20 | Ø d

- 30° | Angle

- MK3 | Tool shank

Description

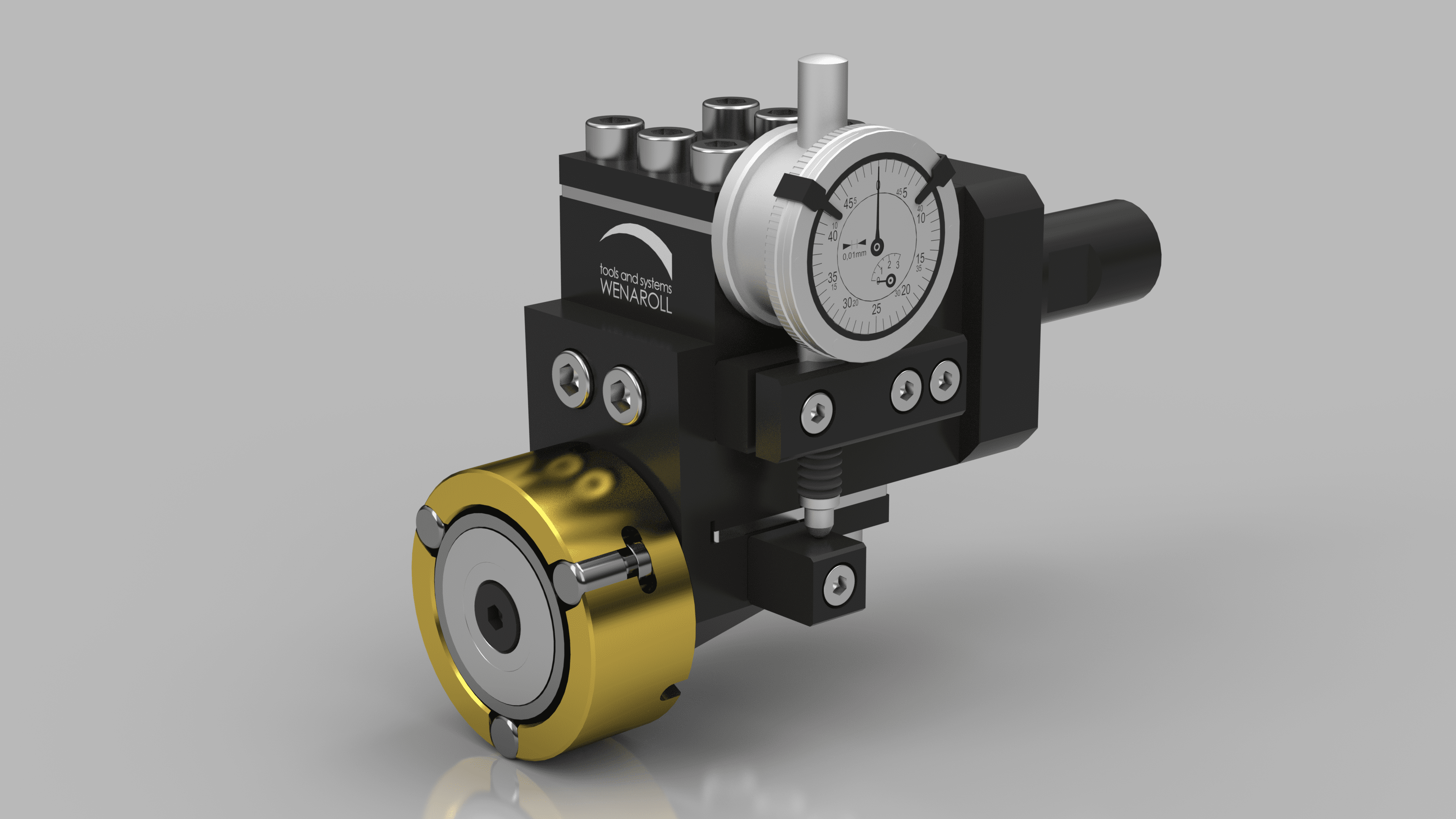

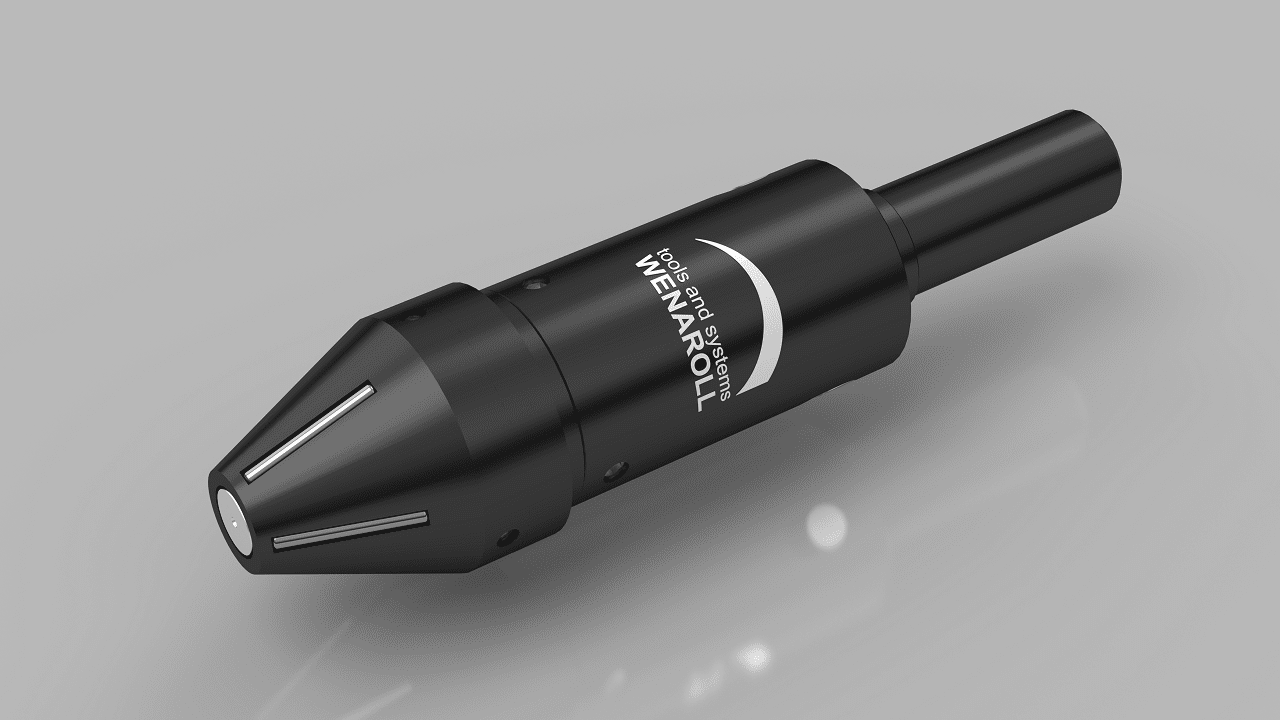

WENAROLL type WIK burnishing tools are used for burnishing internal surfaces of tapers .

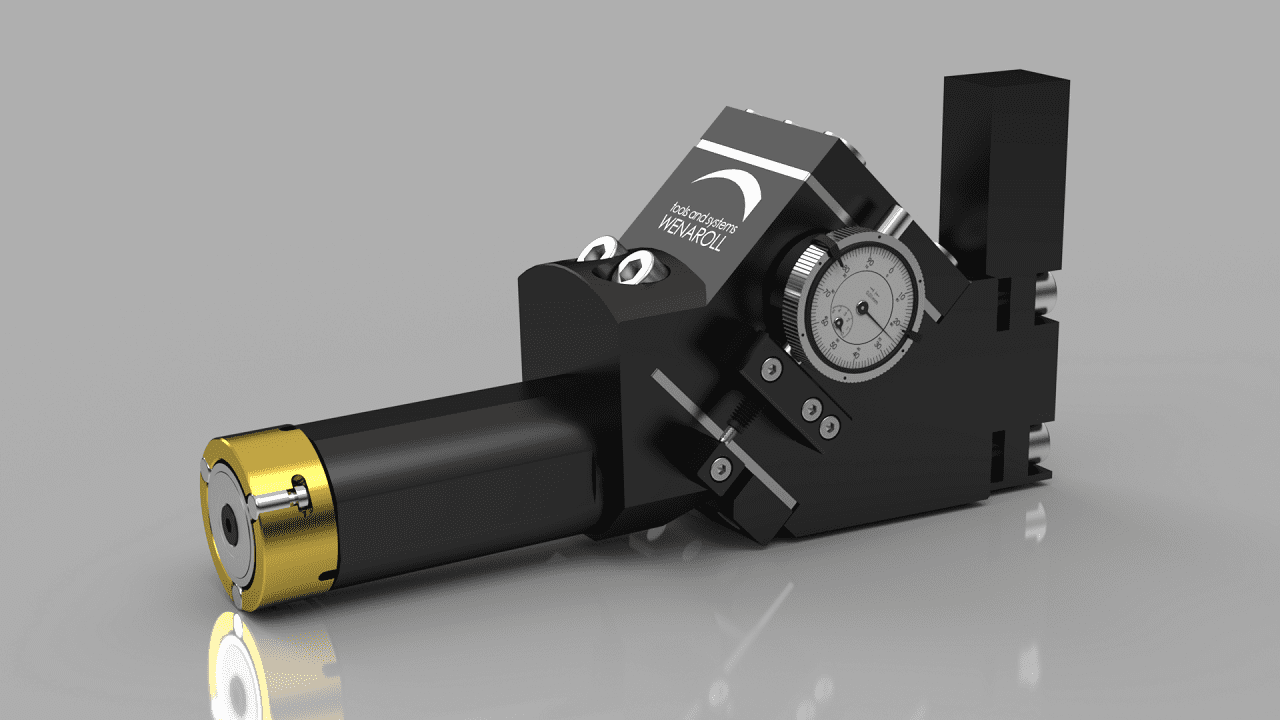

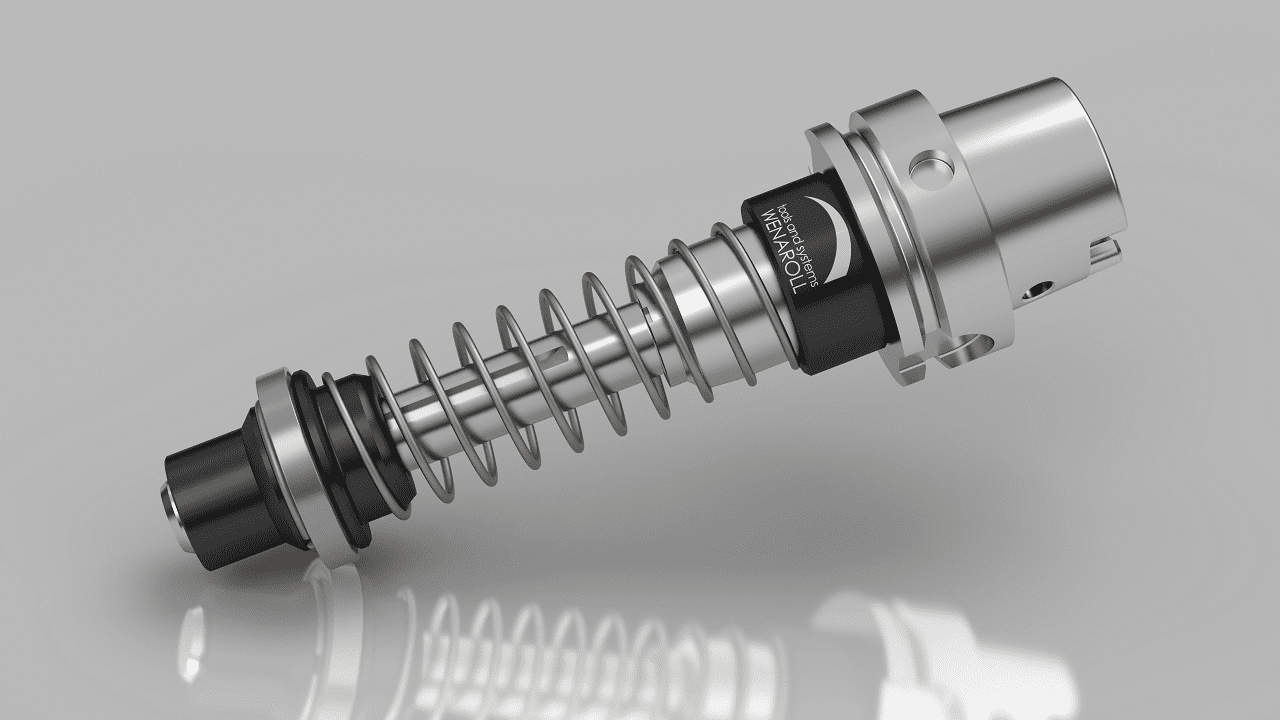

The tool body is equipped with a special spring system, which allows for a specific surface pressure adjustment for each work piece. The spring package is adjusted individually for each tool; thus, we can guarantee an excellent surface finish.

Furthermore, the spring system prevents overload on the tool and the machine. Therefore, an even and continuous load on every work piece is achieved.

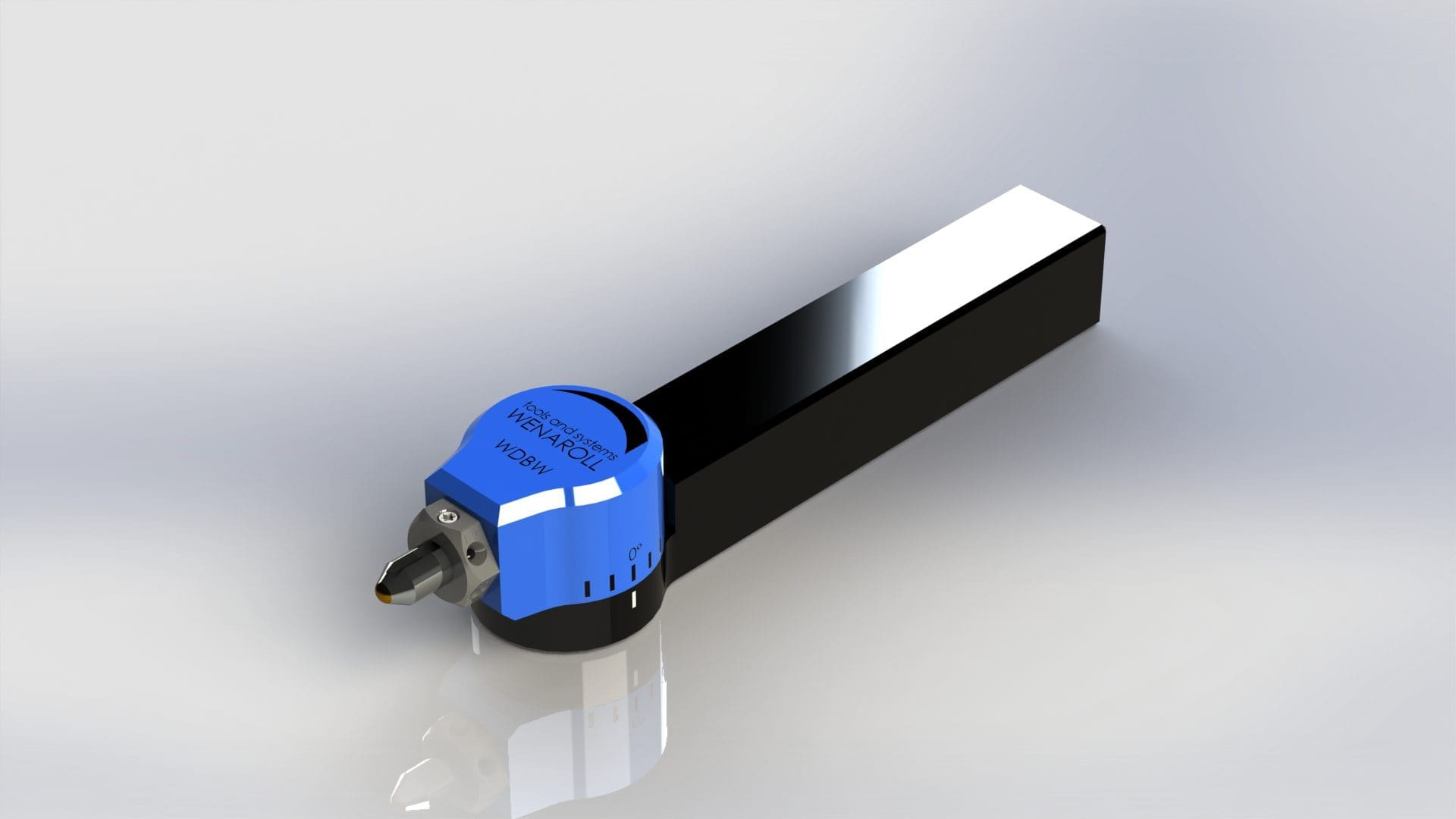

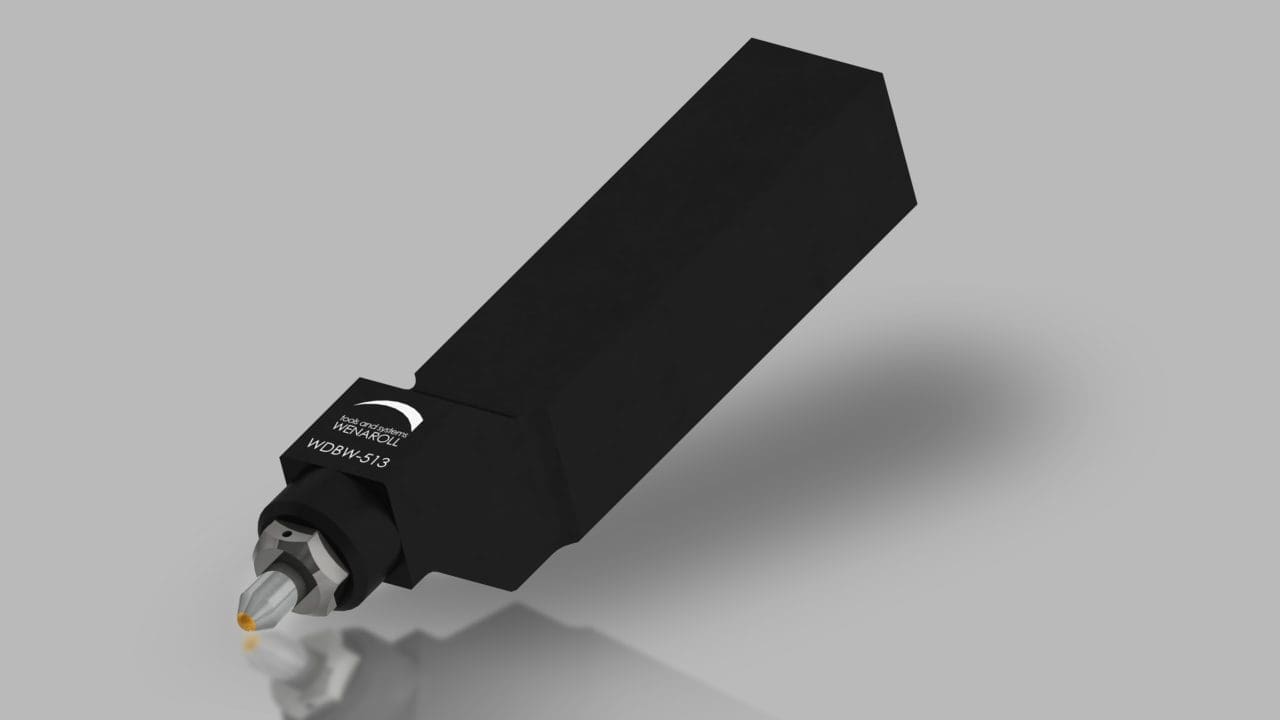

Tool structure

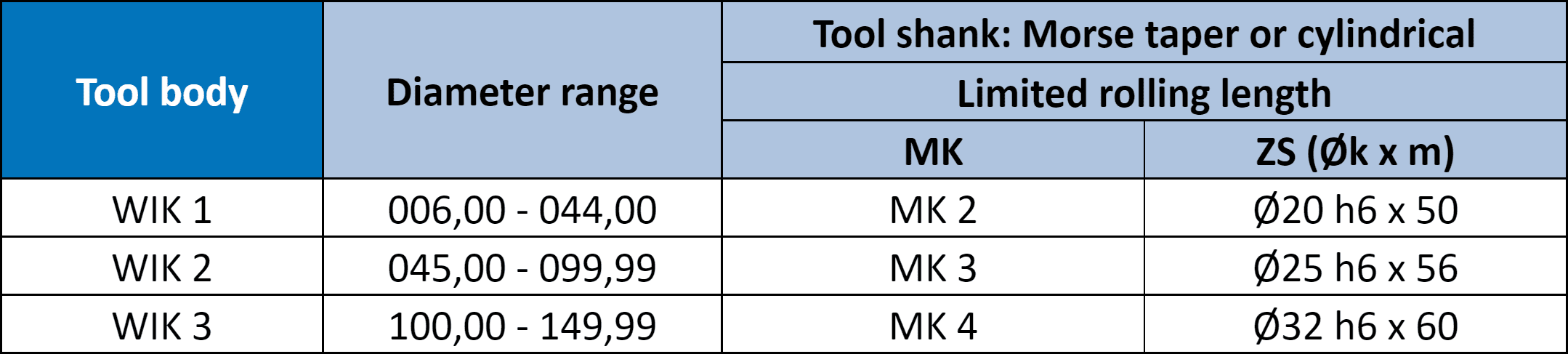

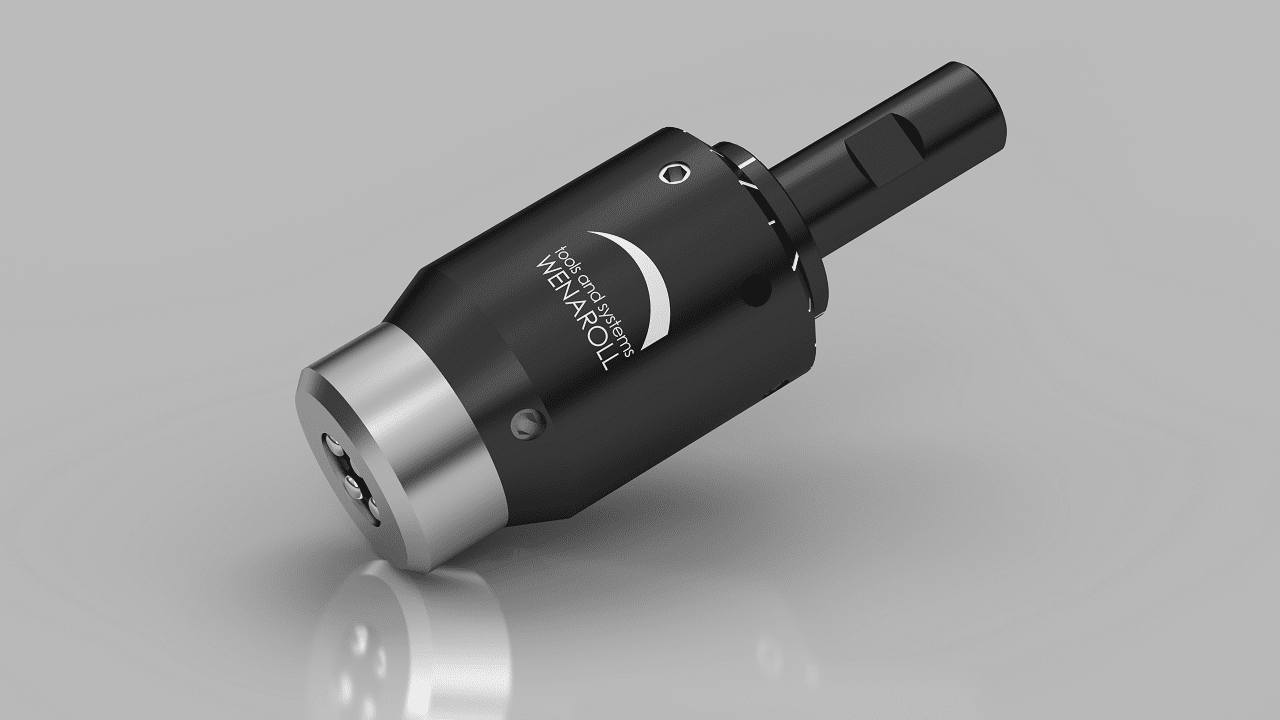

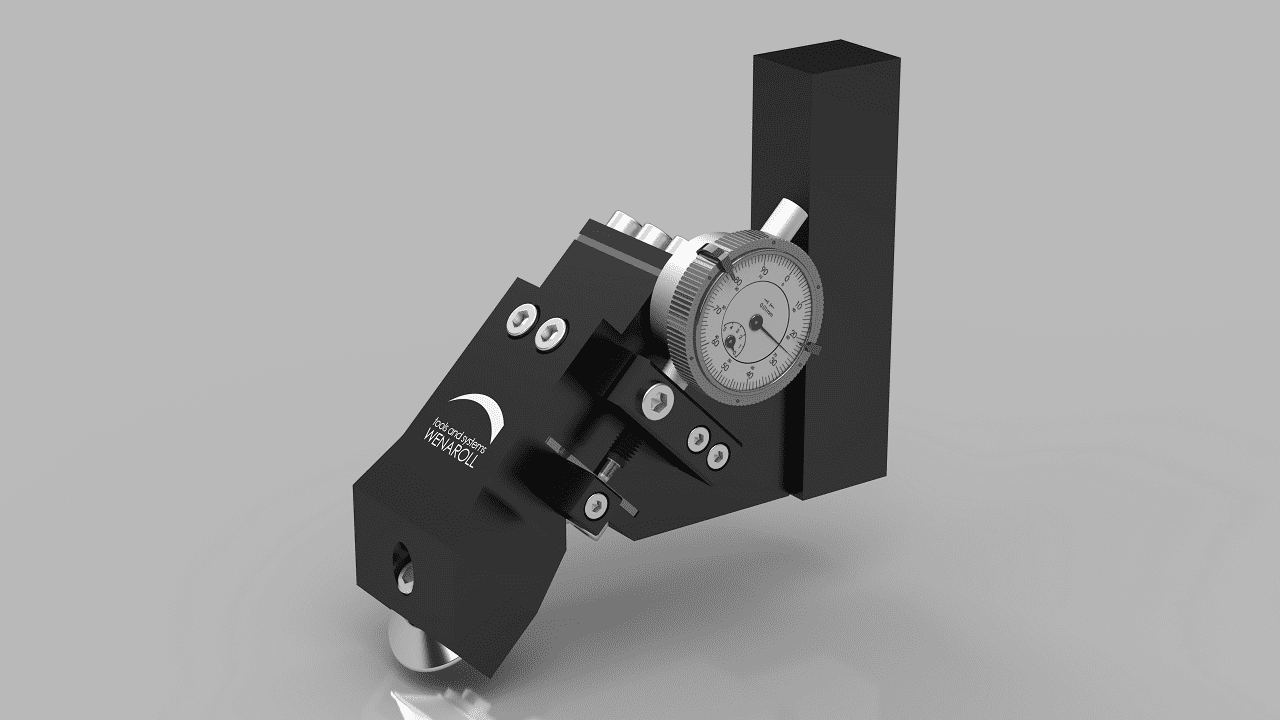

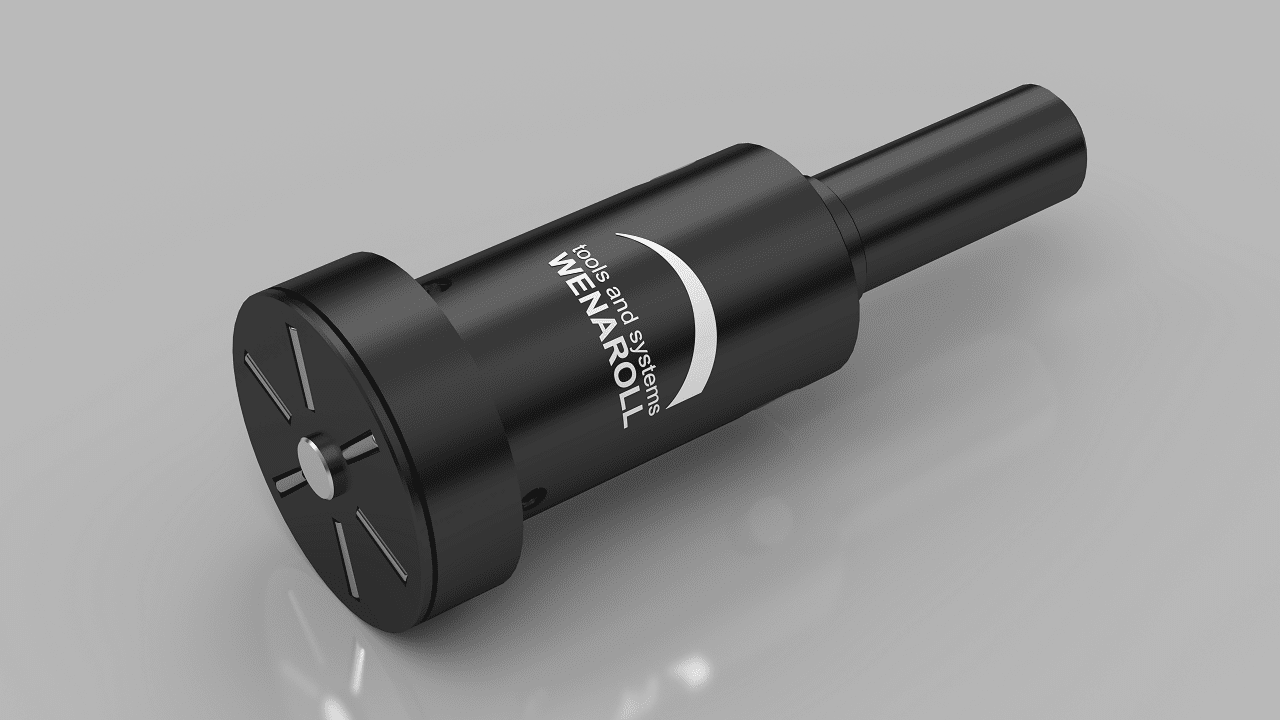

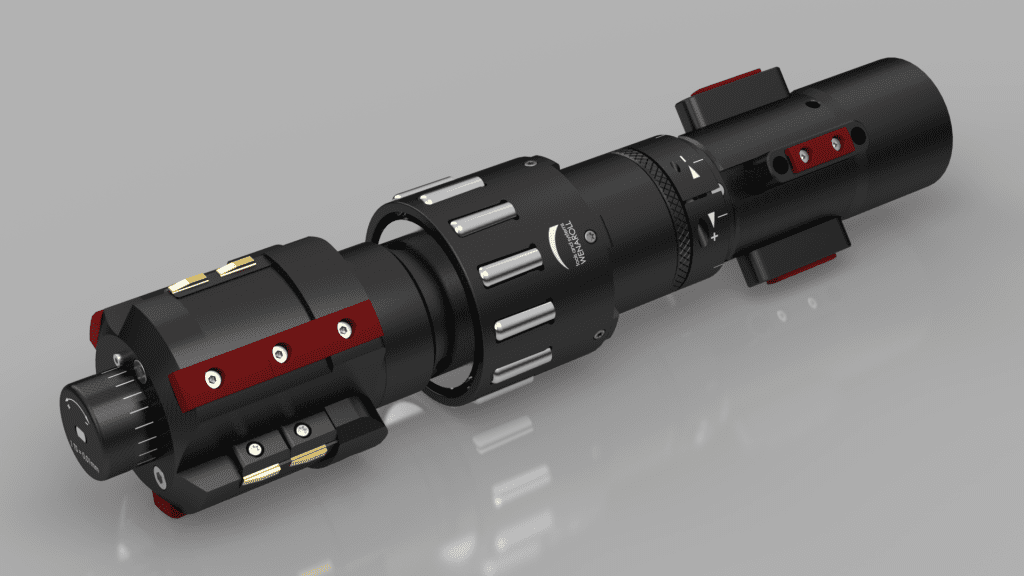

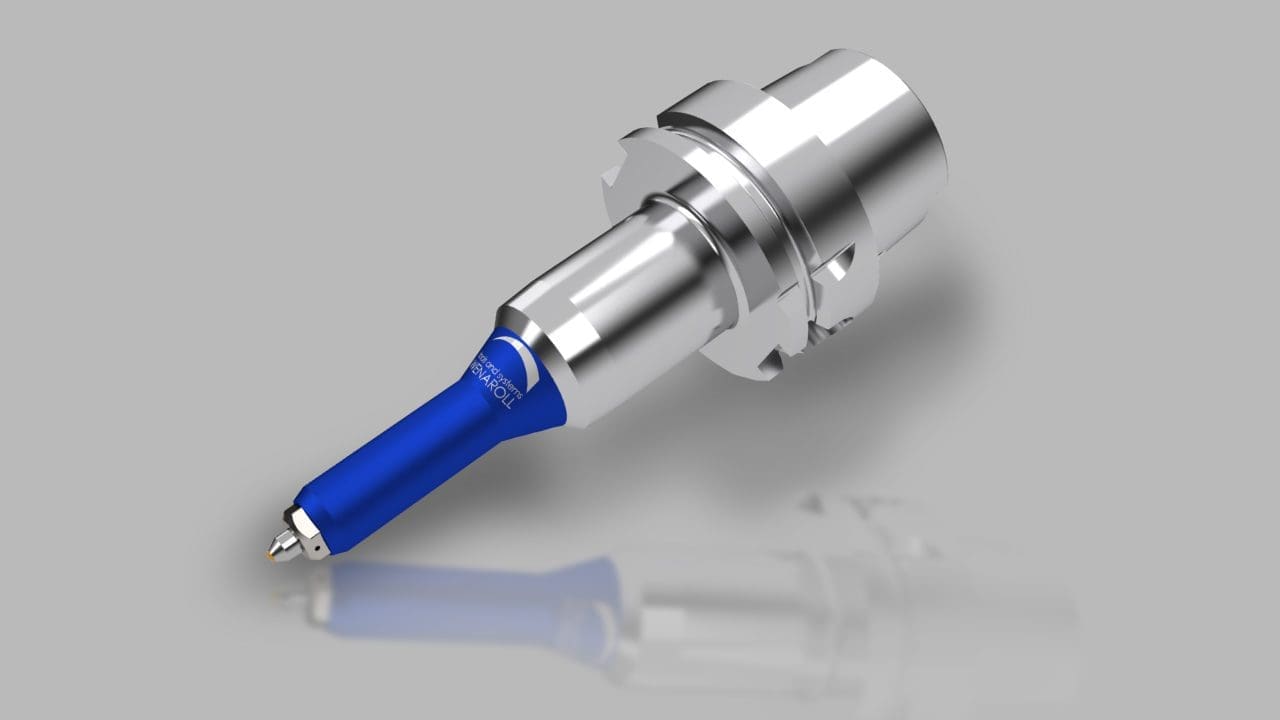

Wenaroll type WIK tools consist of a tool body and a roller burnishing head. The tool body includes a cage that is fitted with a prestressed spring package and an adaptation to the machine.

The tool shank can either be cylindrical, morse taper or any other tool shank type on request. The cage, rollers and cone are wear parts and are easily exchangeable.

The spring arrangement inside the tool is individually designed for every application, therefore please keep in mind that every tool is custom made and we do not have these tools in stock.

Process

These tools cannot be adjusted. The burnishing process starts when the tool head, which has been specially adapted to the workpiece contour, approaches/touches the workpiece with a defined force. The tool or the workpiece must rotate during the machining process. These tools can be used on any machine on which a rotating process takes place (lathes or milling machines, machining centers, special machines).

Data sheet - Technology Guide

All dimensions in mm. EV: Self-feeding | MV: Machine-feeding