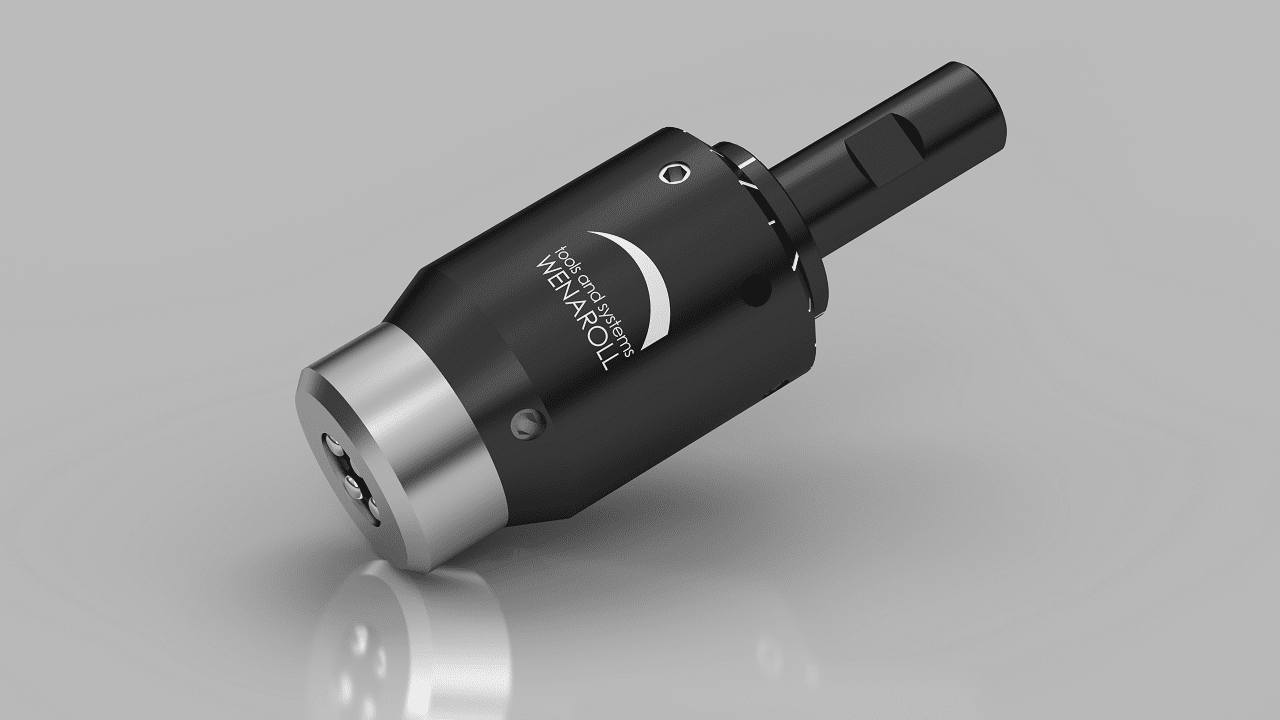

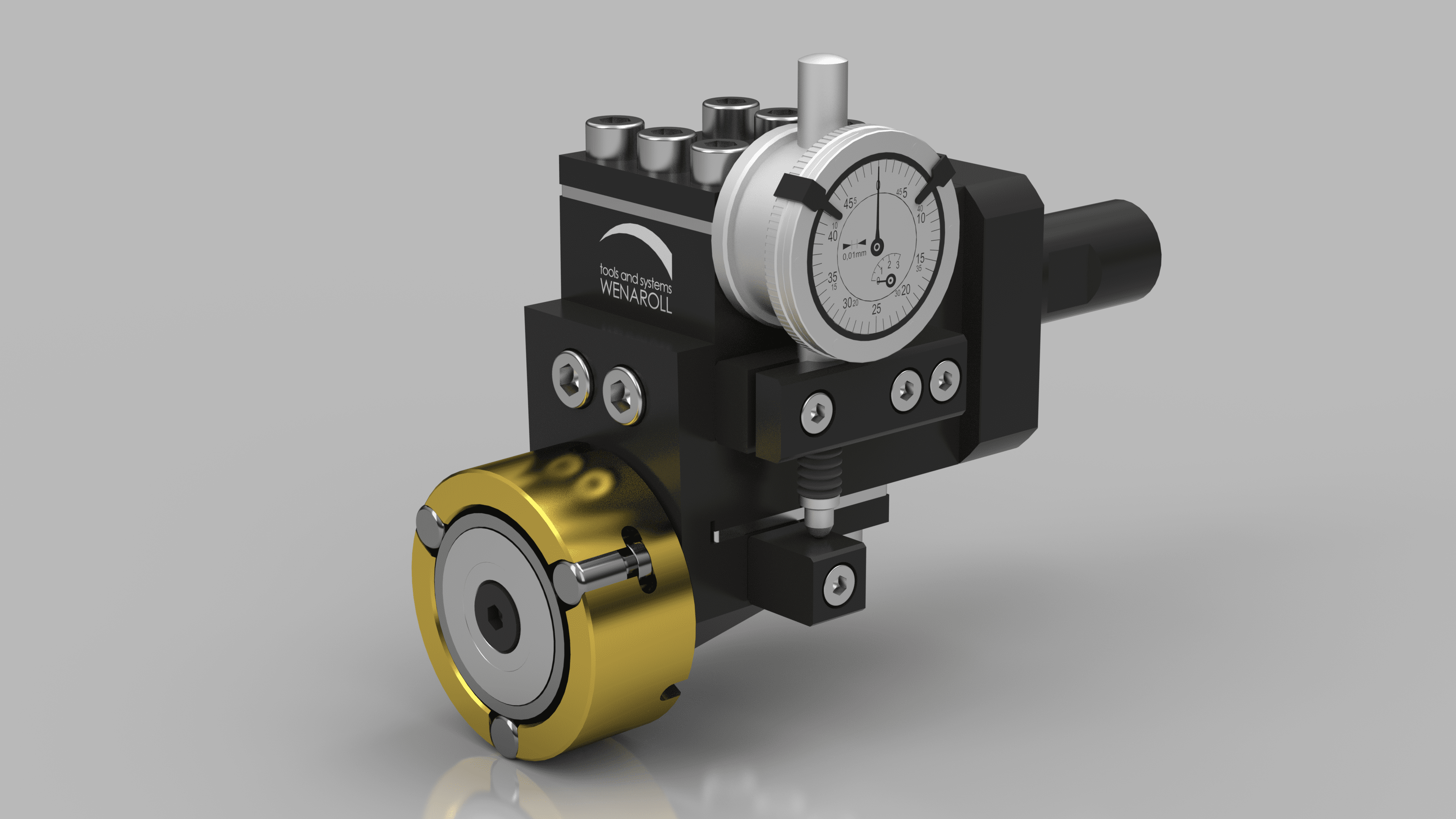

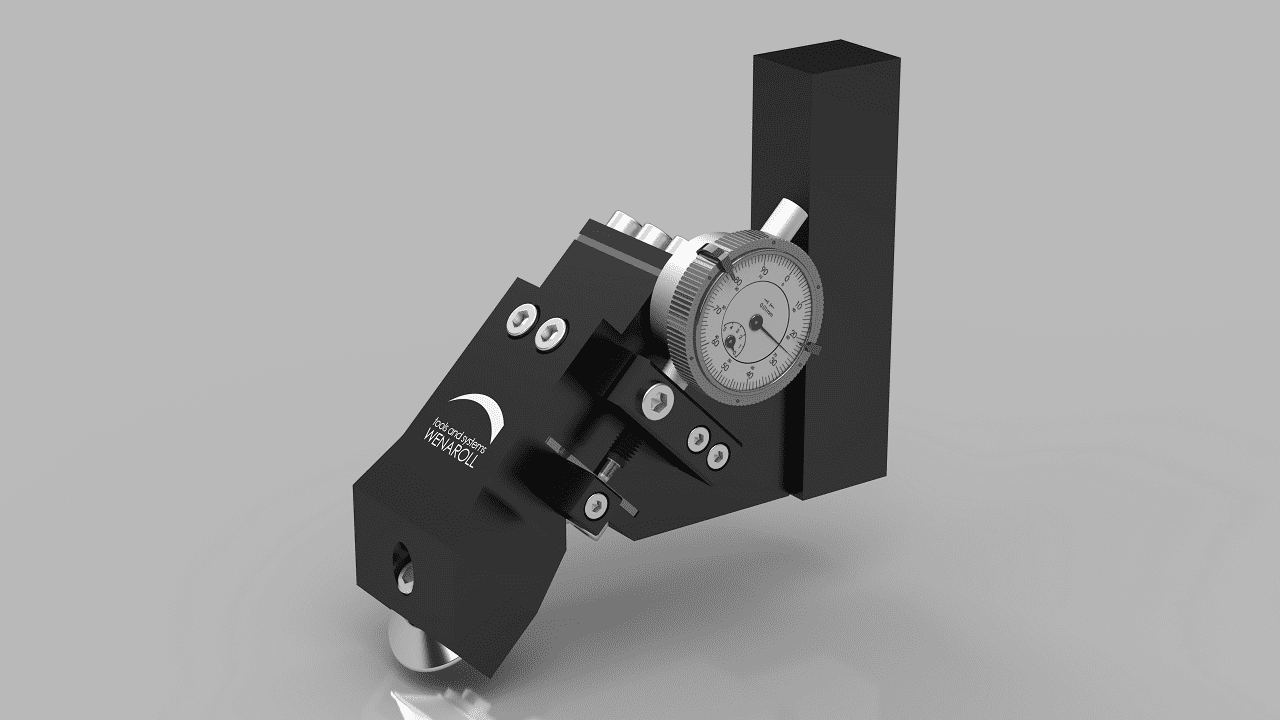

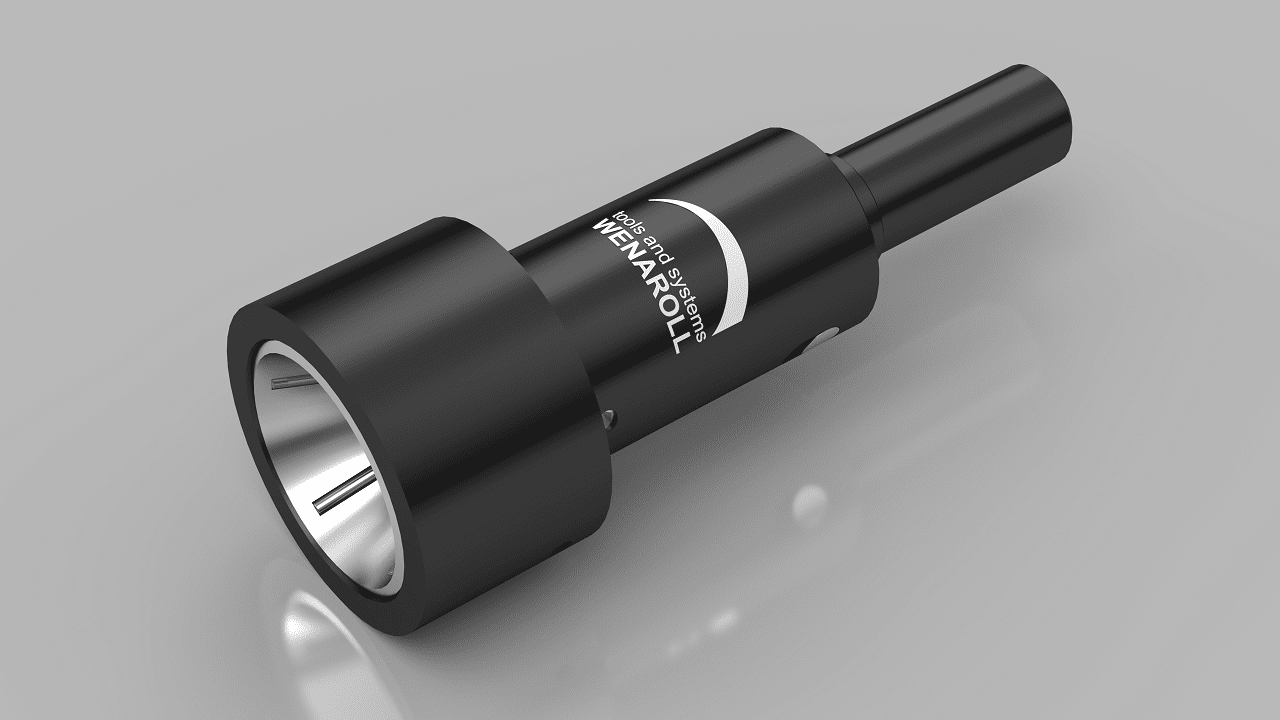

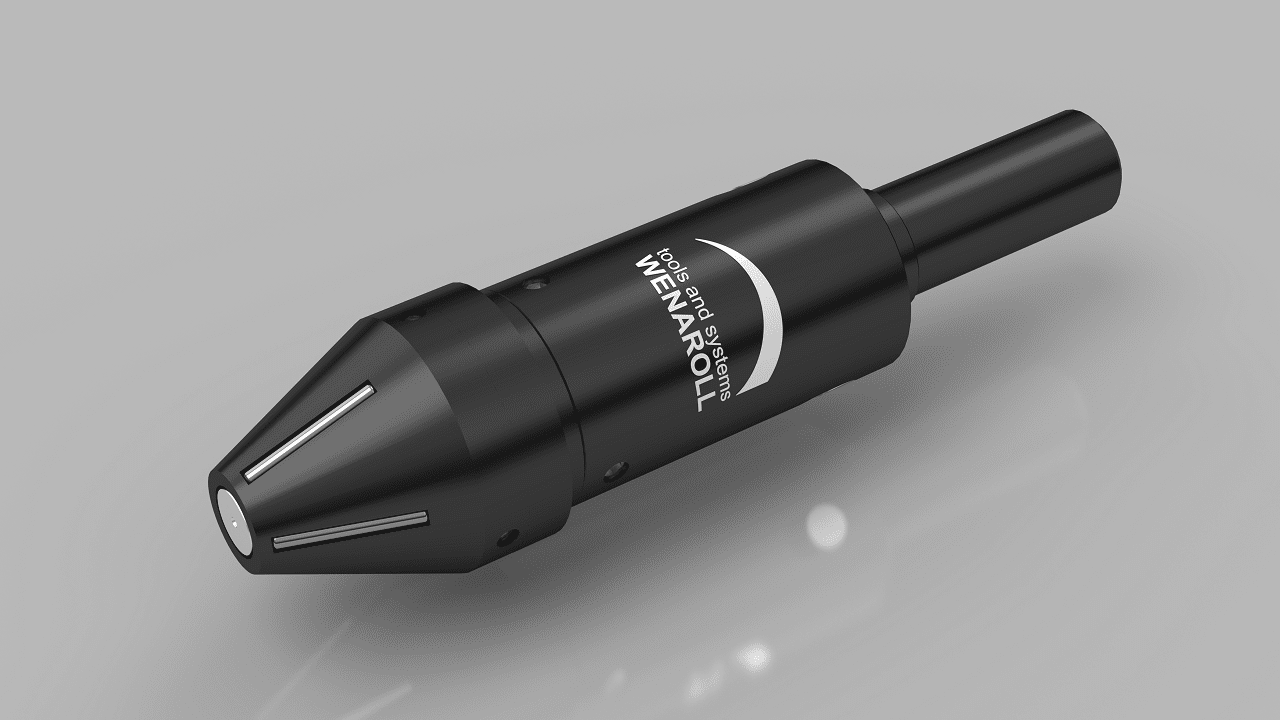

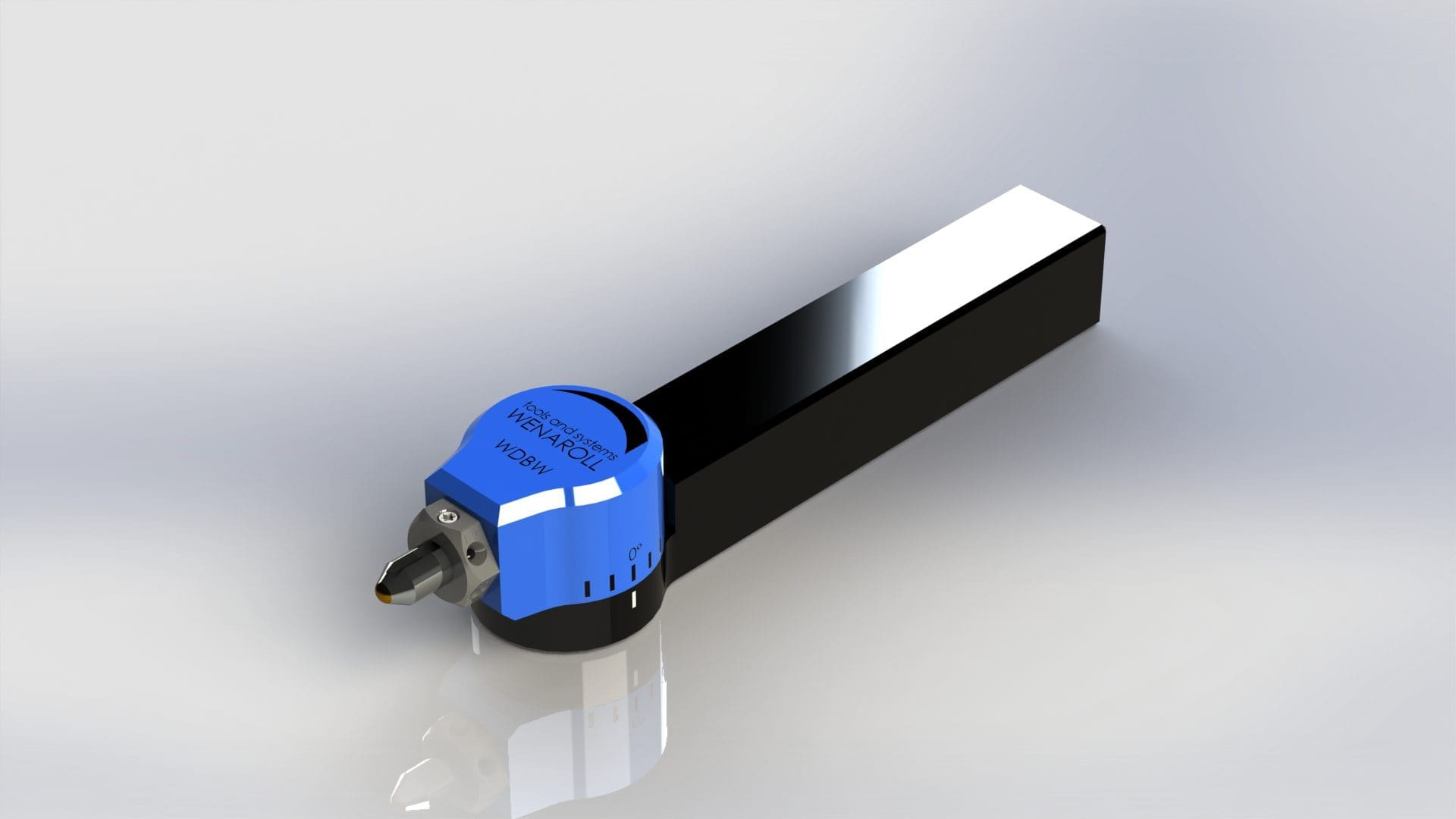

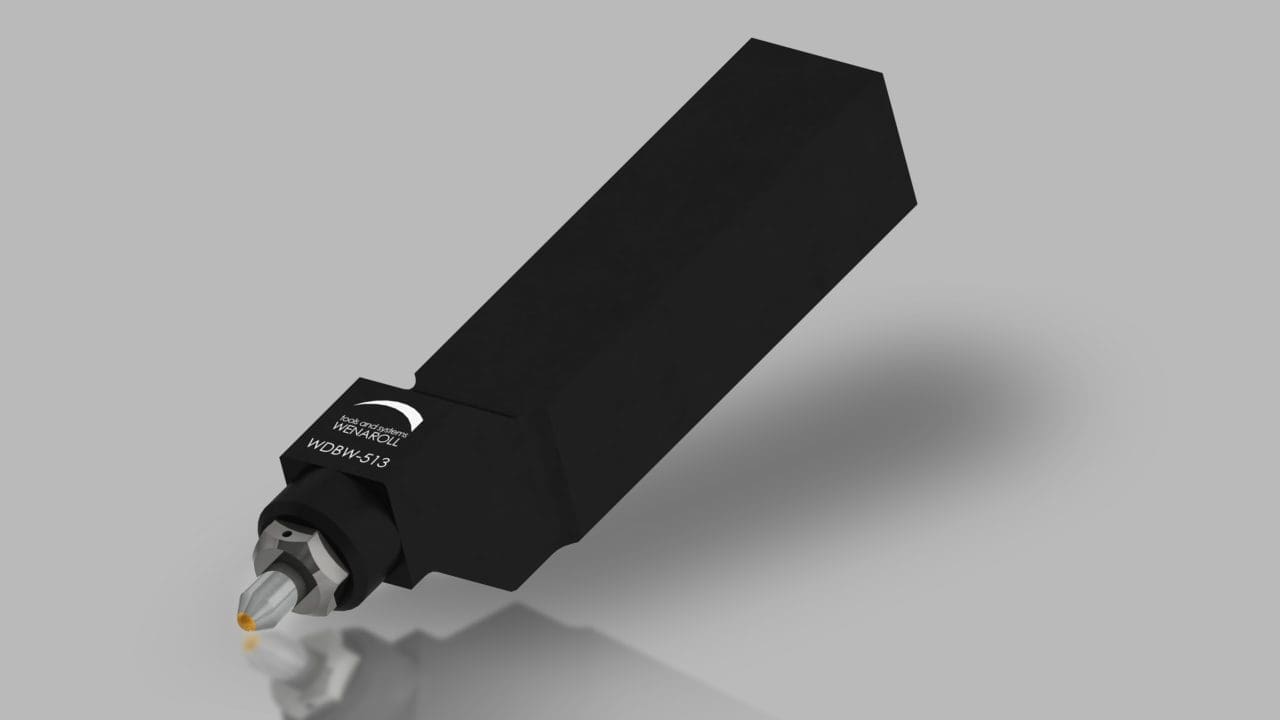

Diamond Tool Type WDBW

Diamond Tool Type WDBW

Advantages

Order example

Machining parameters

Advantages

Type WDBW

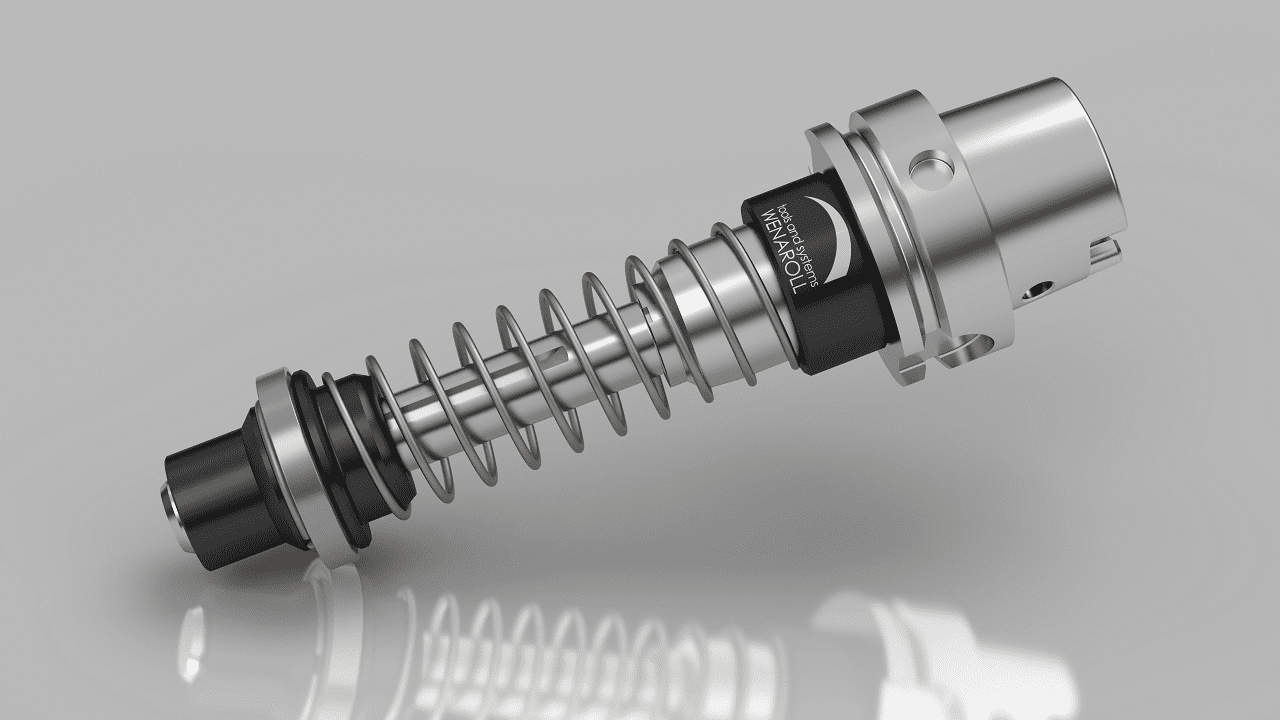

- Fast, efficient and cost-effective roller burnishing

- Tolerance compensation infinitely adjustable via spring force

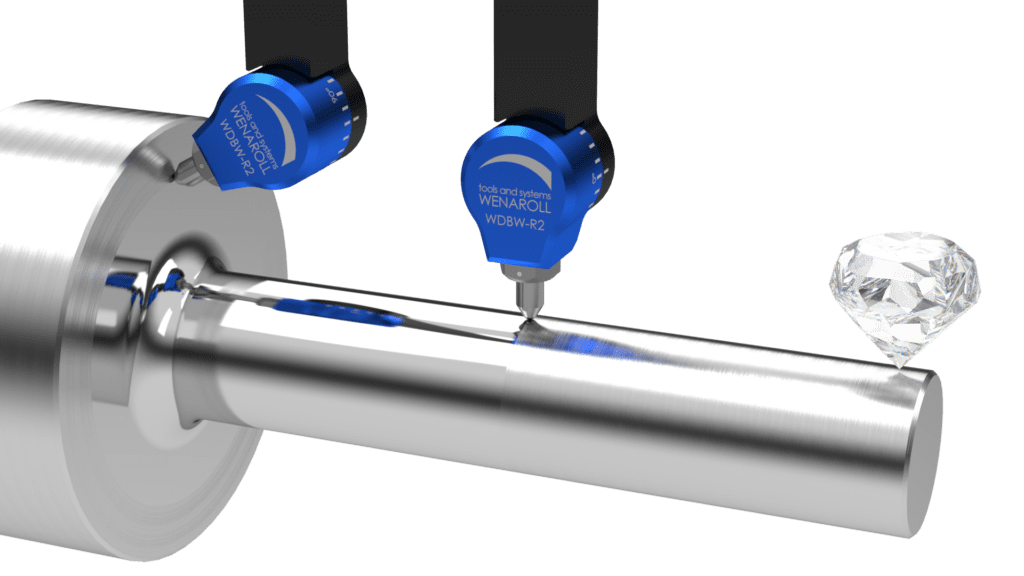

- Highly polished diamond for highest surface quality with roughness depths down to below Rz 1µm

- Diamond carrier interchangeable

- Ideal for internal tube machining medium and small series, as well as prototypes

- Suitable for all materials up to over 60 HRC and high-strength materials such as titanium or platinum

Order example

| Tool holder | Tip radius |

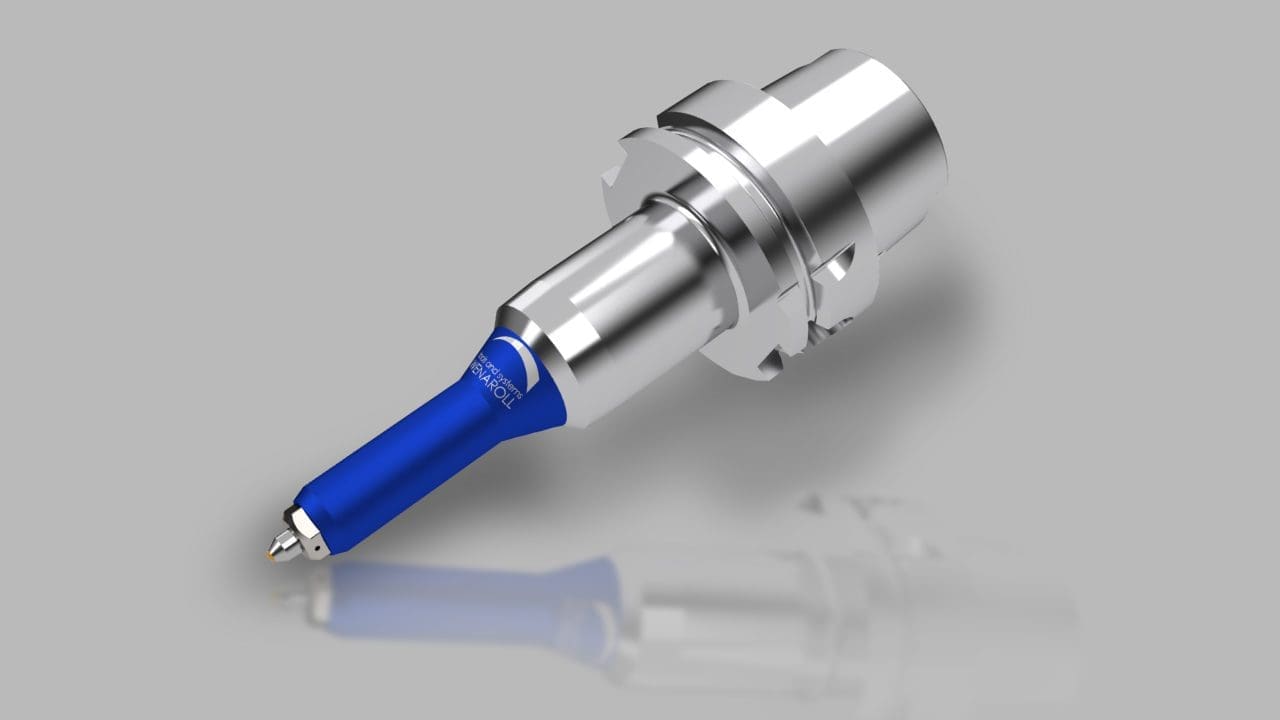

| For WDBW-512: Shank SL8; SL10; SL12; SL16; SL20; SL25For WDBW-515: Cylindrical shank D32 (longer processing lengths) for pipe diameters from Ø50 mm | R1.0; R2.0 other radii also possible on request |

WDBW-515-R2-D32-L300

-

- WDBW 515: Tool type

- R2: Tip radius

- D32: Tool cylindrical shank Ø32

- L300: Complete length L=300mm

Machining parameters

- VC max. up to 160 m/min

- Feeding up to 0,2 mm/U

- Measurement of the workpiece

(depending on material) in the range 0,015 – 0,02 - Tool preload max. 2 mm

- Coolant Emulsion or oil

- Preparation Finely turned or ground surface RZ 10 μm

Description

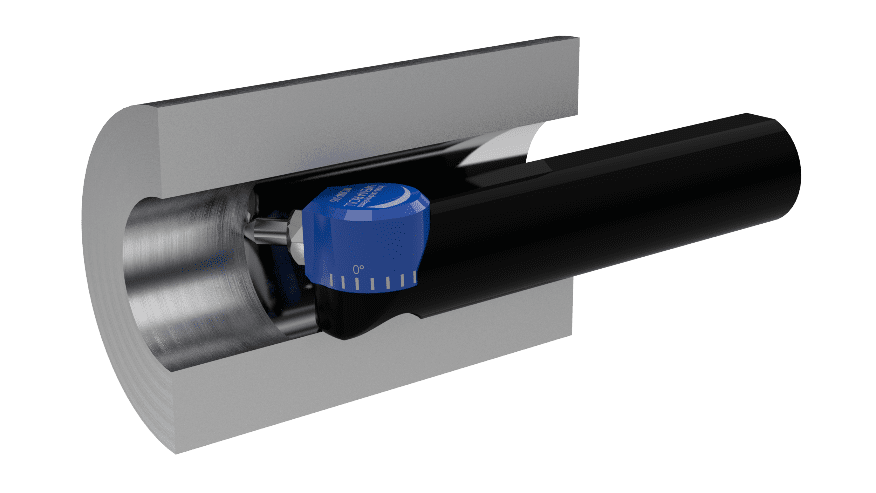

WENAROLL diamond tools with type WDBW have been specially developed for internal pipe machining of thin-walled surfaces. The spring-loaded diamond tip can be pressed onto the surface with the necessary force via the infeed of the machine, enabling machining of materials up to over 60 HRC. In order to be able to machine more complex contours, the tip of these tools (WDBW-512 and WDBW-515) can be rotated 90° and fixed in position. The diamond tool type WDBW-512 is our standard tool. For longer machining lengths we offer the diamond tool type WDBW-515 for lengths up to 300 mm.