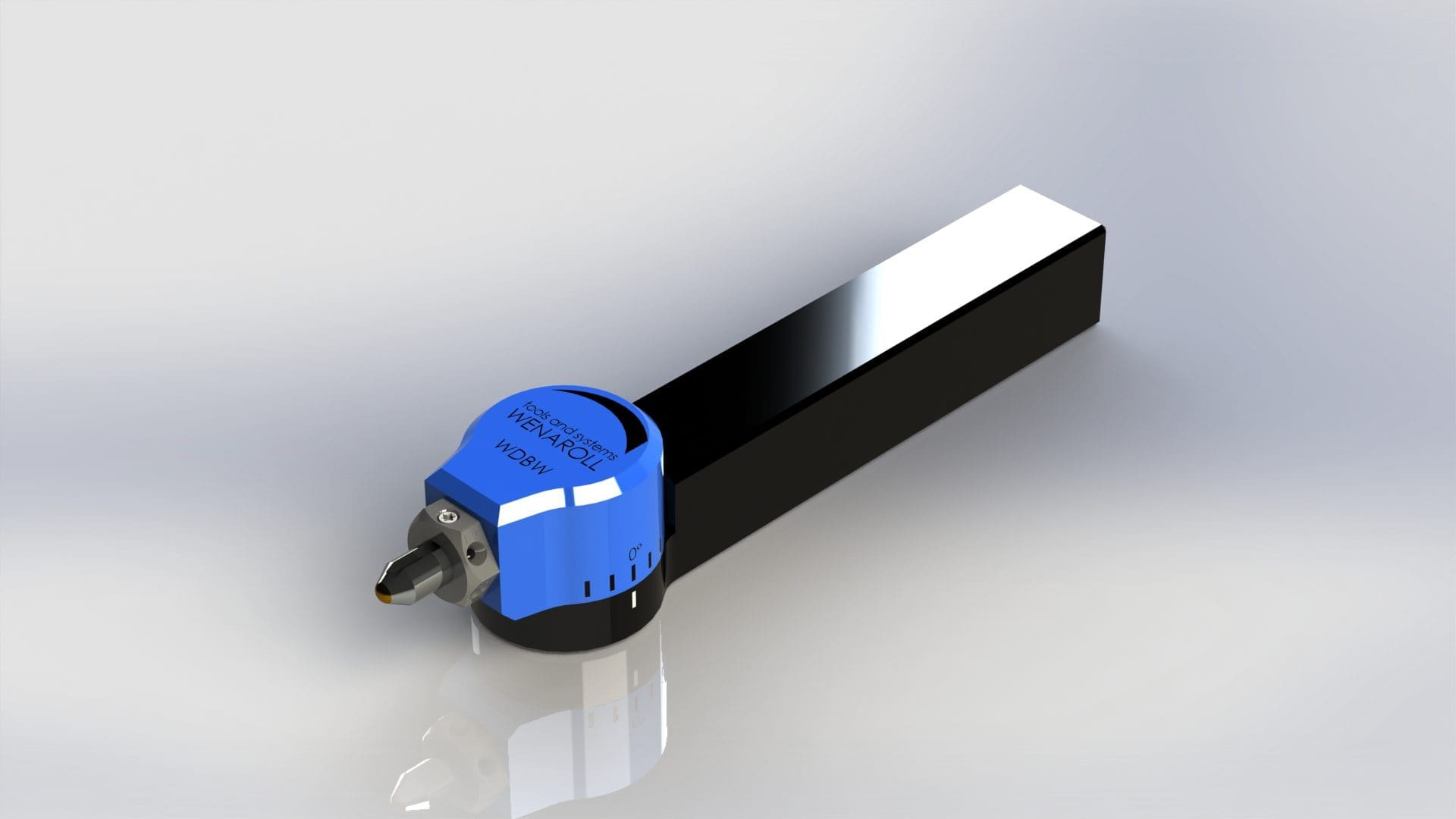

Type ERGK

- Surfaces with a quality of Rz < 1 µm can be produced quickly

- Long lifetime for wear parts

- Chipless and quiet process

- Processing up to front surface possible

- Wear parts can be exchanged

- Barely any lubricant / cooling required

- Can be used on almost every machine

- Stepless adjustment of roller force

- Roller force can be determined easily

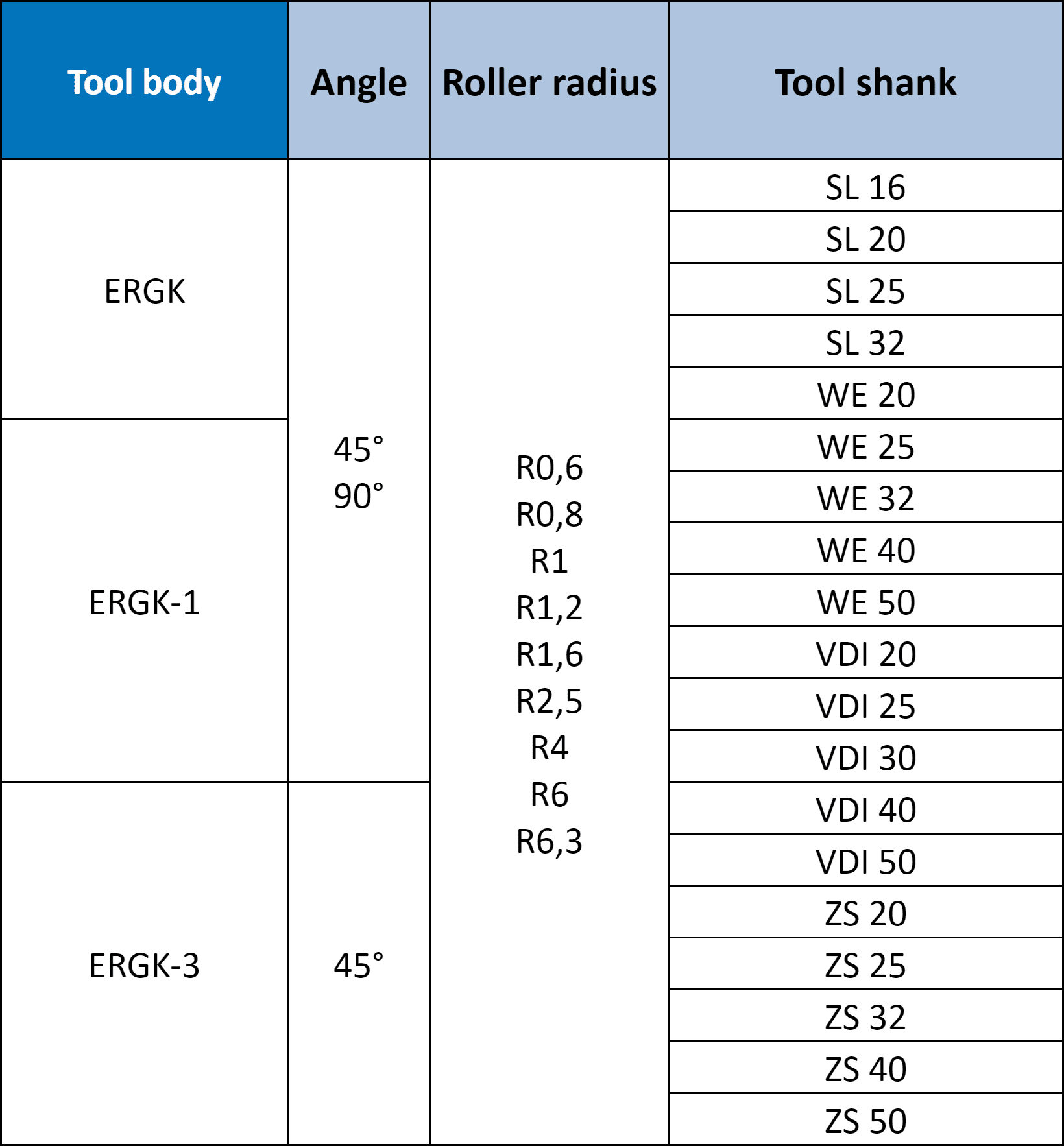

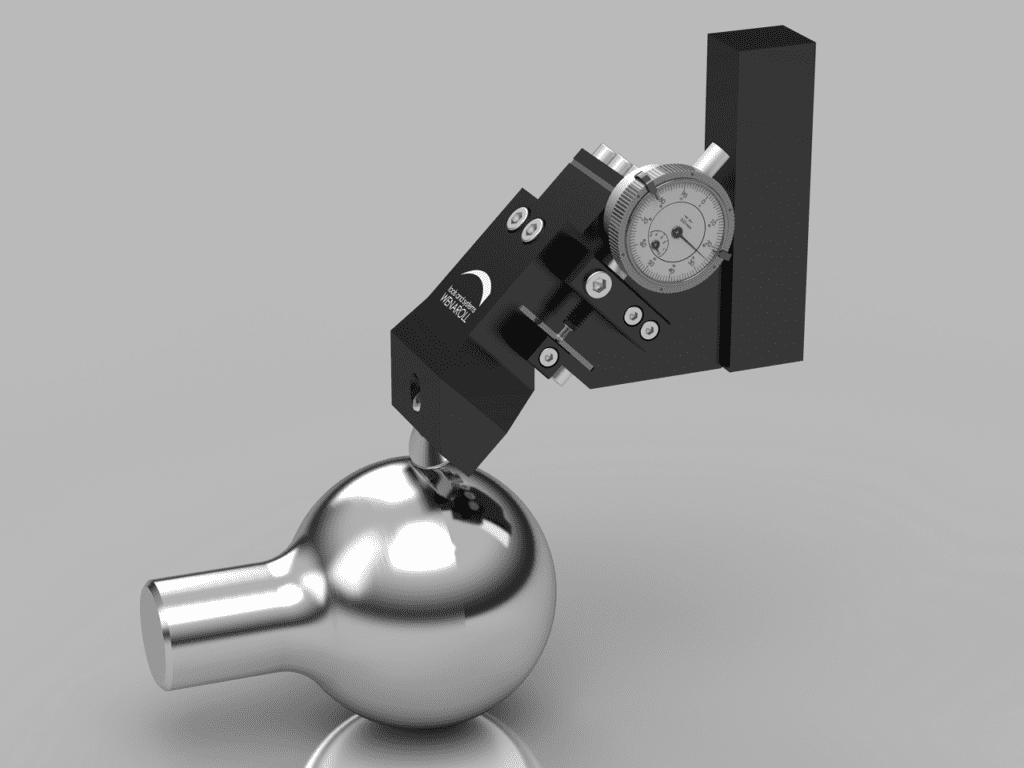

ERGK-45-2,5R-VDI30

- ERGK | Tool body

- 45 | Tool is angled at 45°

- 2,5R | Roller radius 2,5

- VDI30 | Tool shank VDI 30

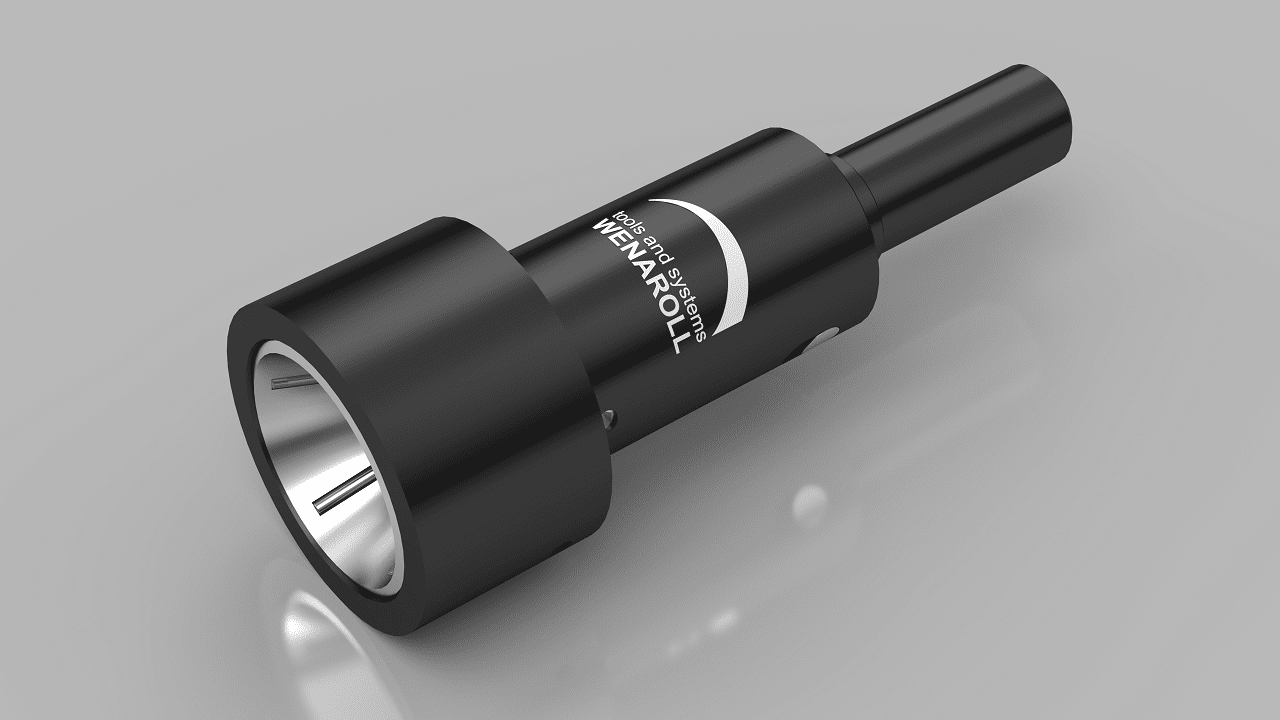

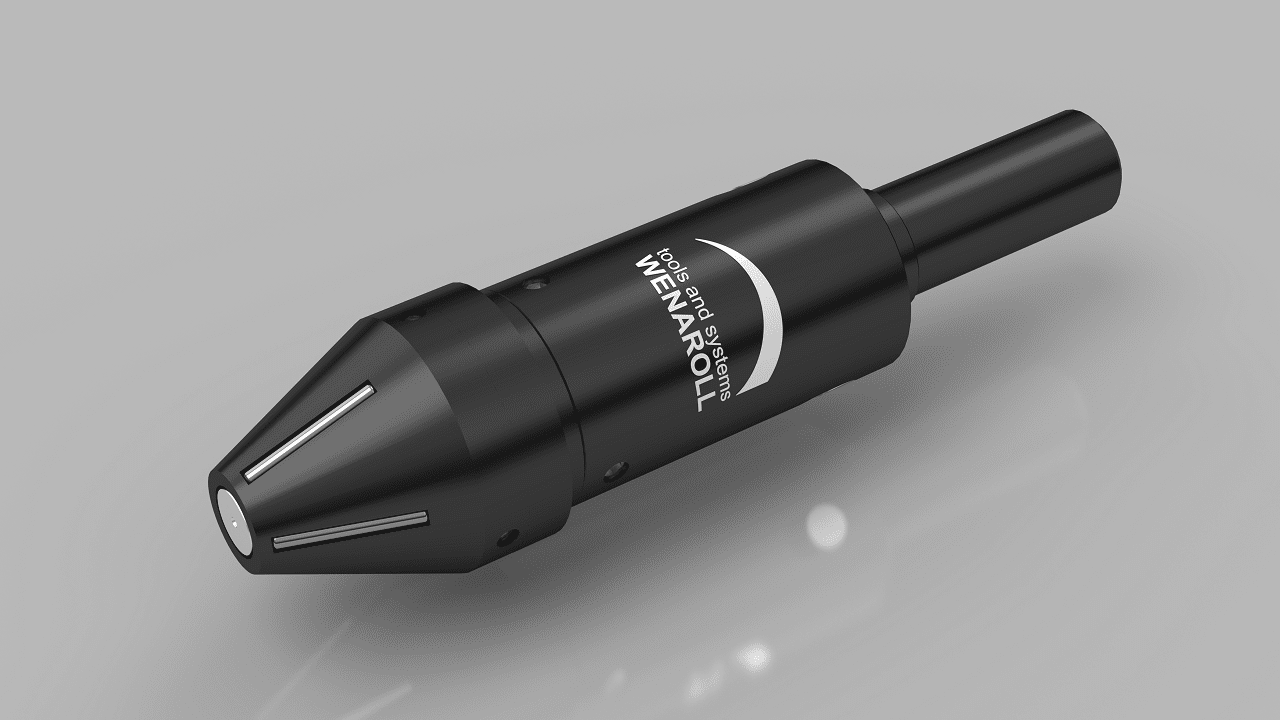

Description

WENAROLL ERGK burnishing tools are designed for processing cylindrical shafts, plane surfaces, as well as spherical and tapered work pieces. The ERGK tools have an angled contour roller that is especially suited for burnishing radii. The angle of the roller can either be 45° or 90° and enables you to process the whole radius.

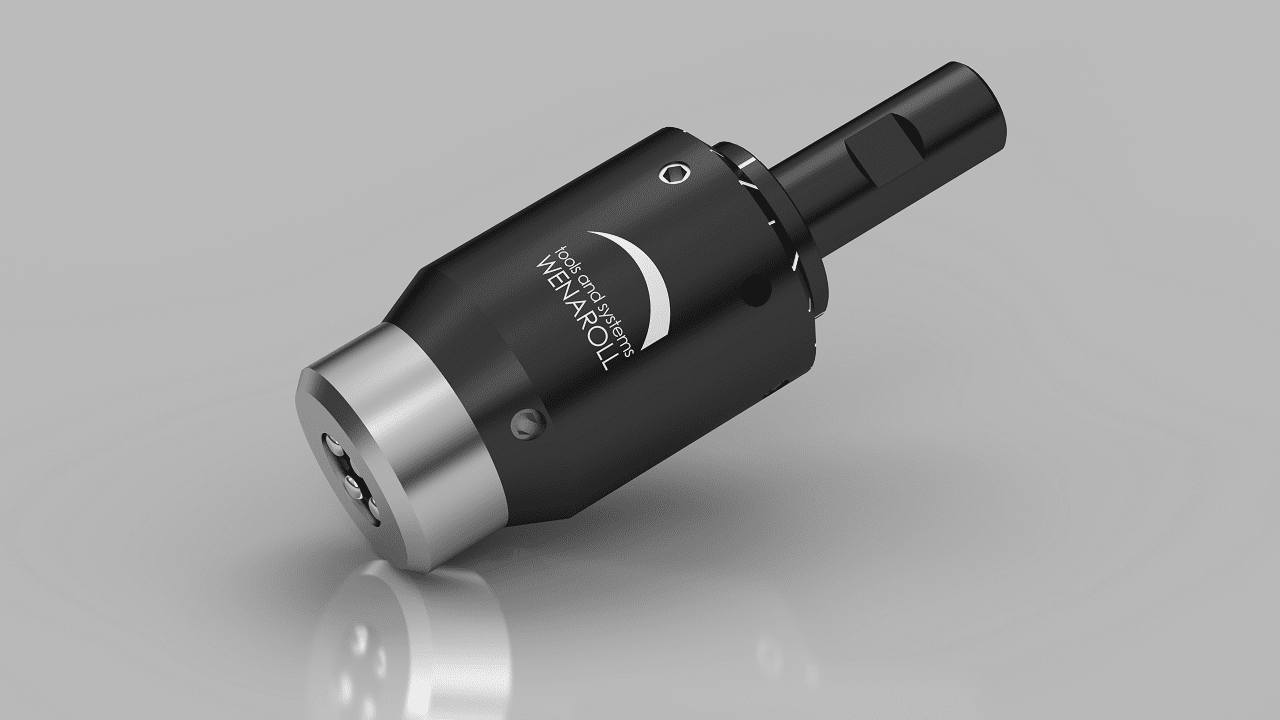

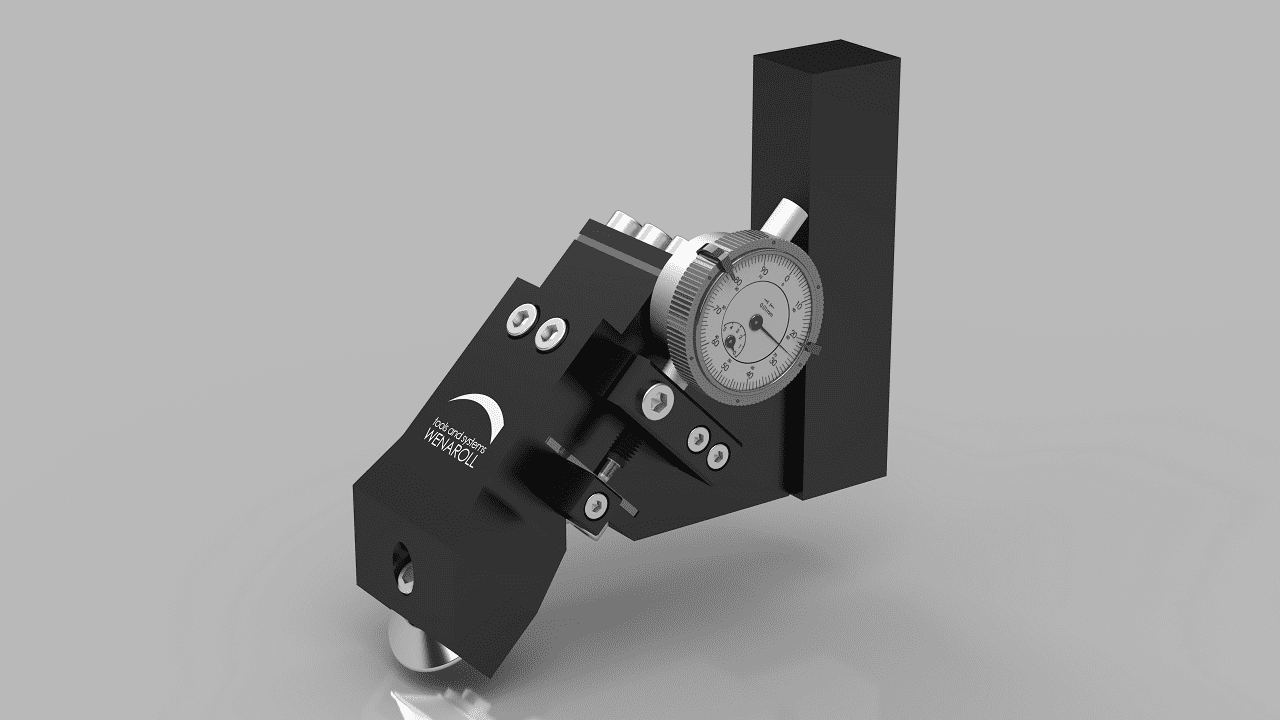

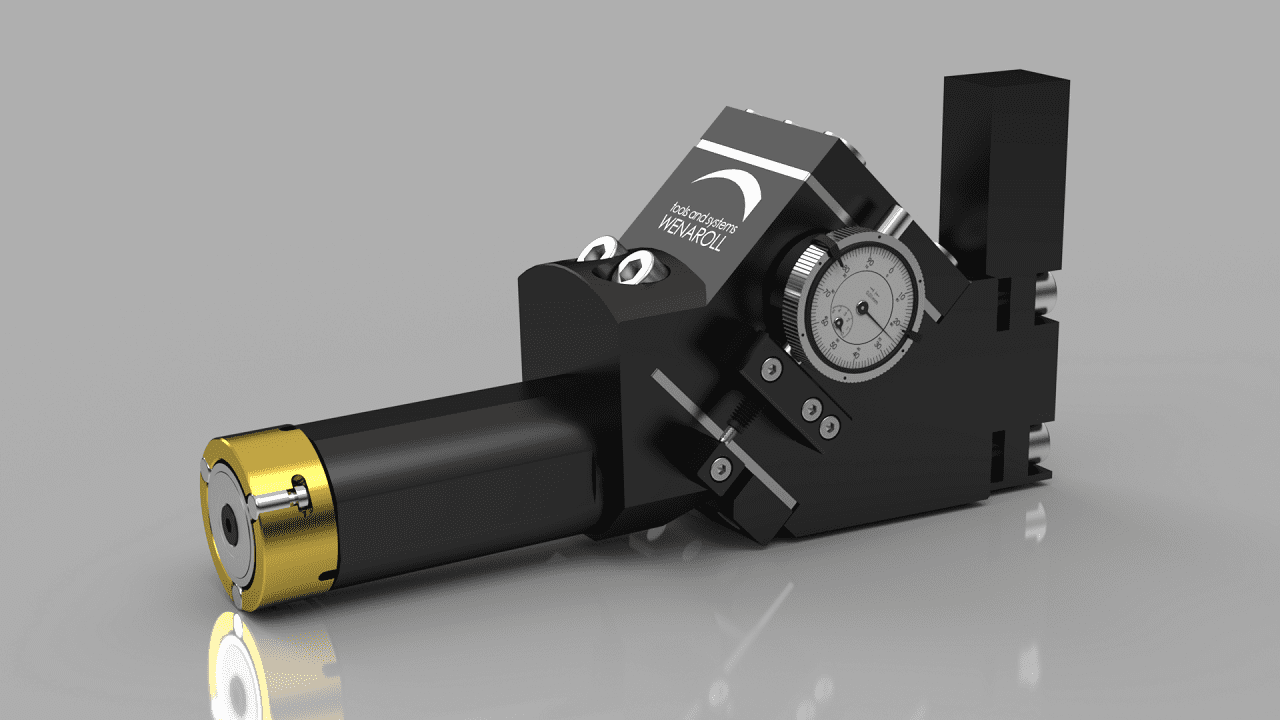

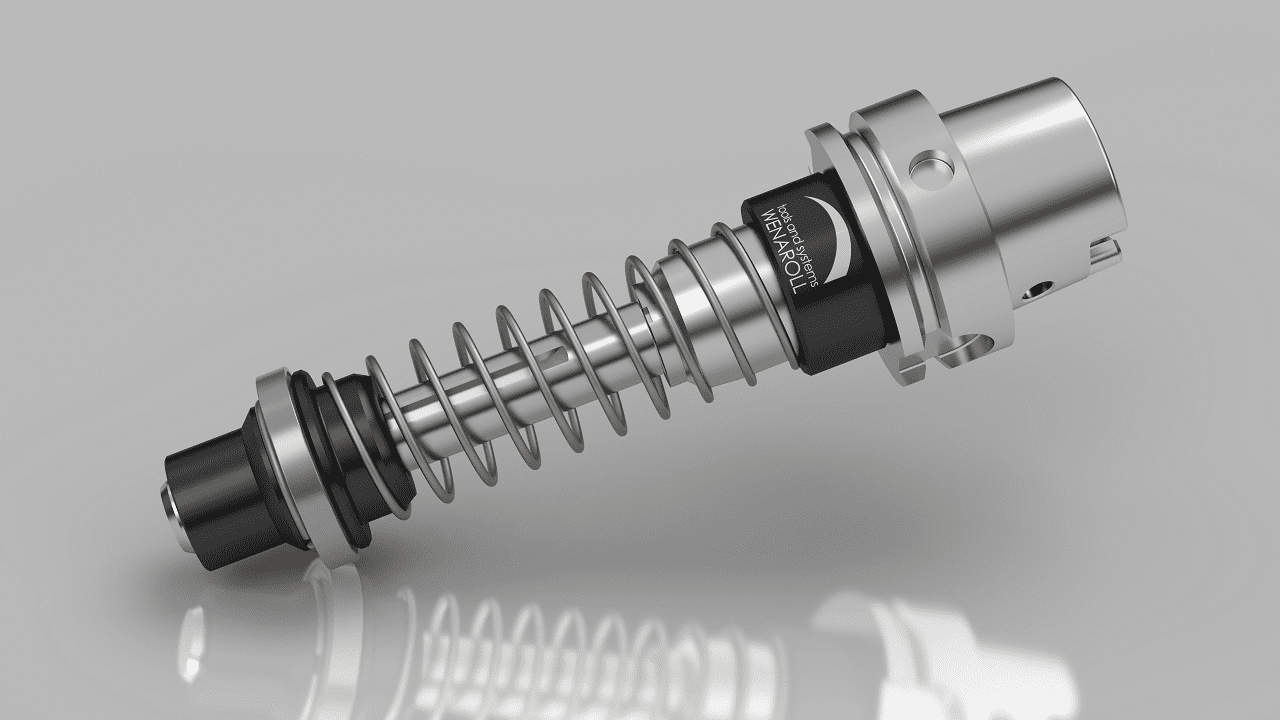

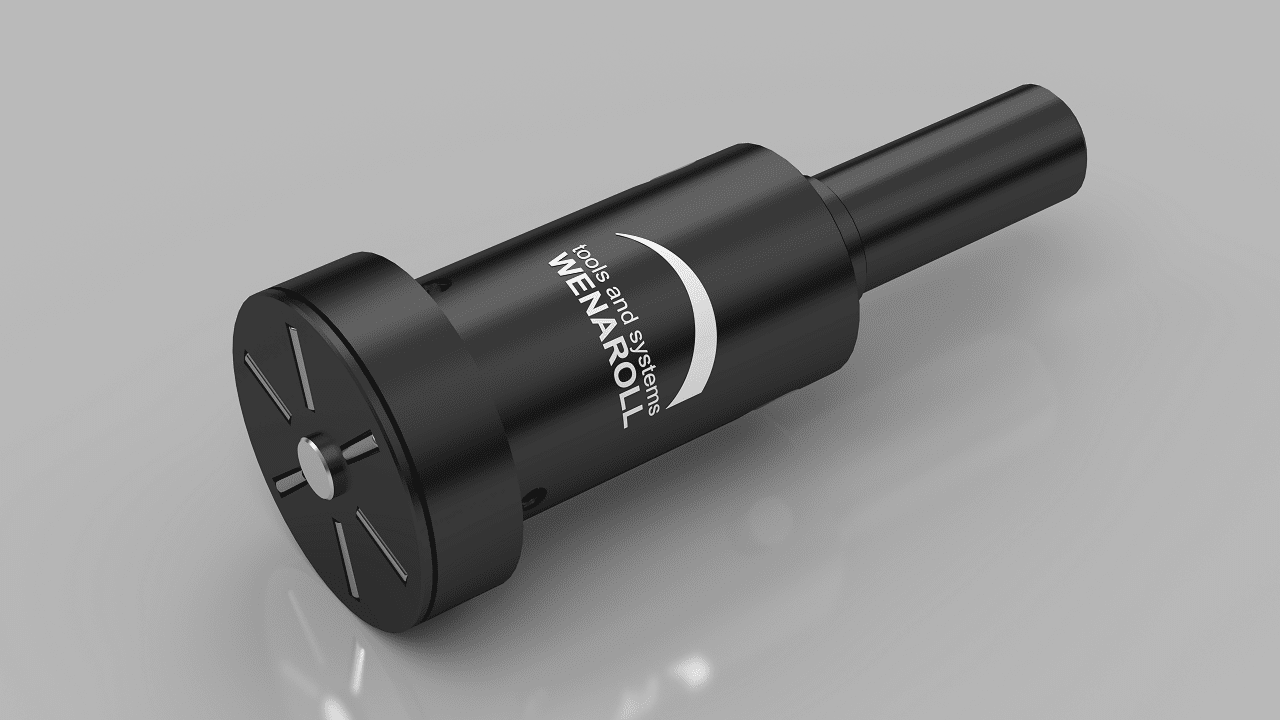

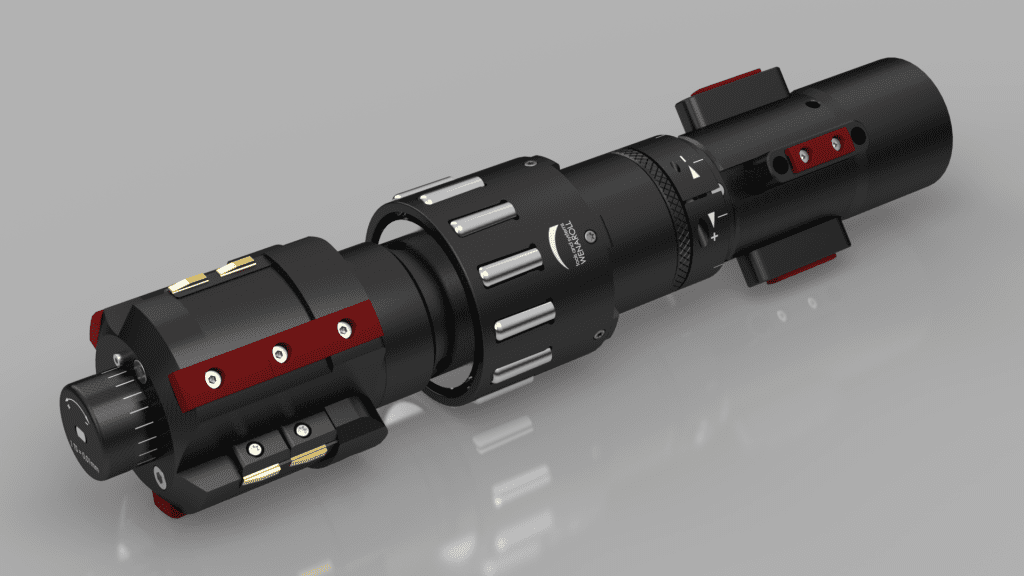

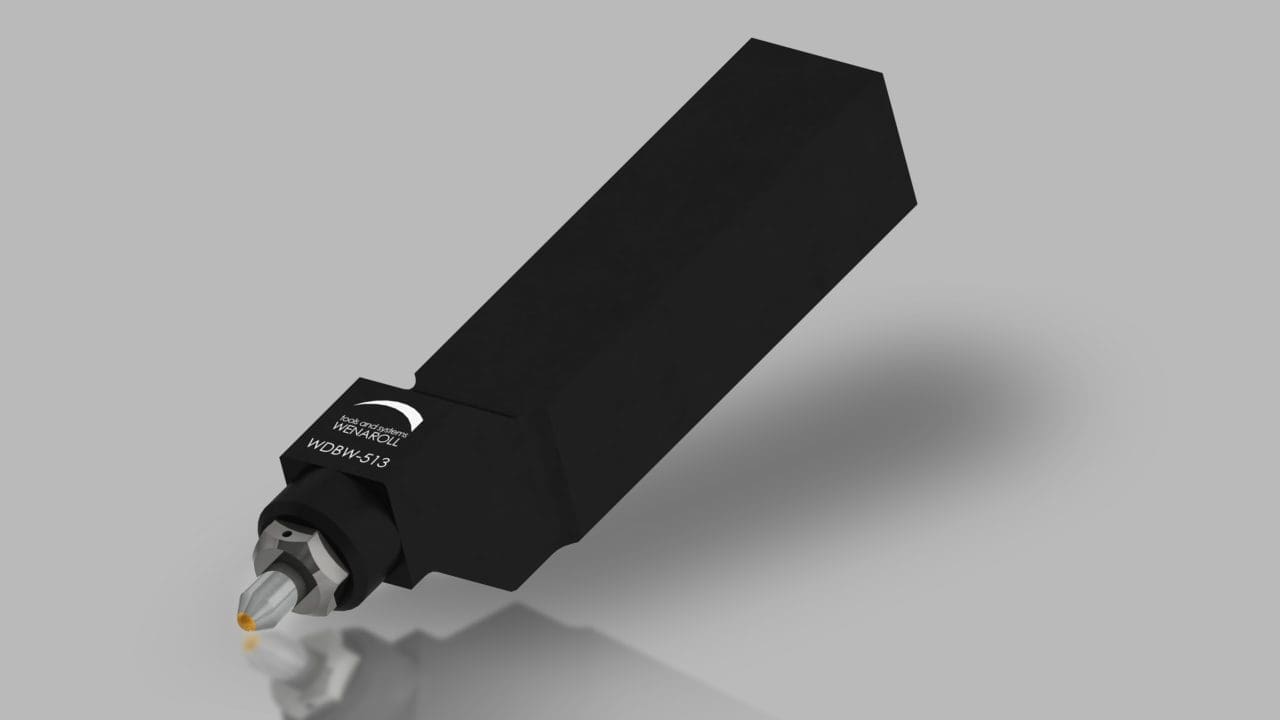

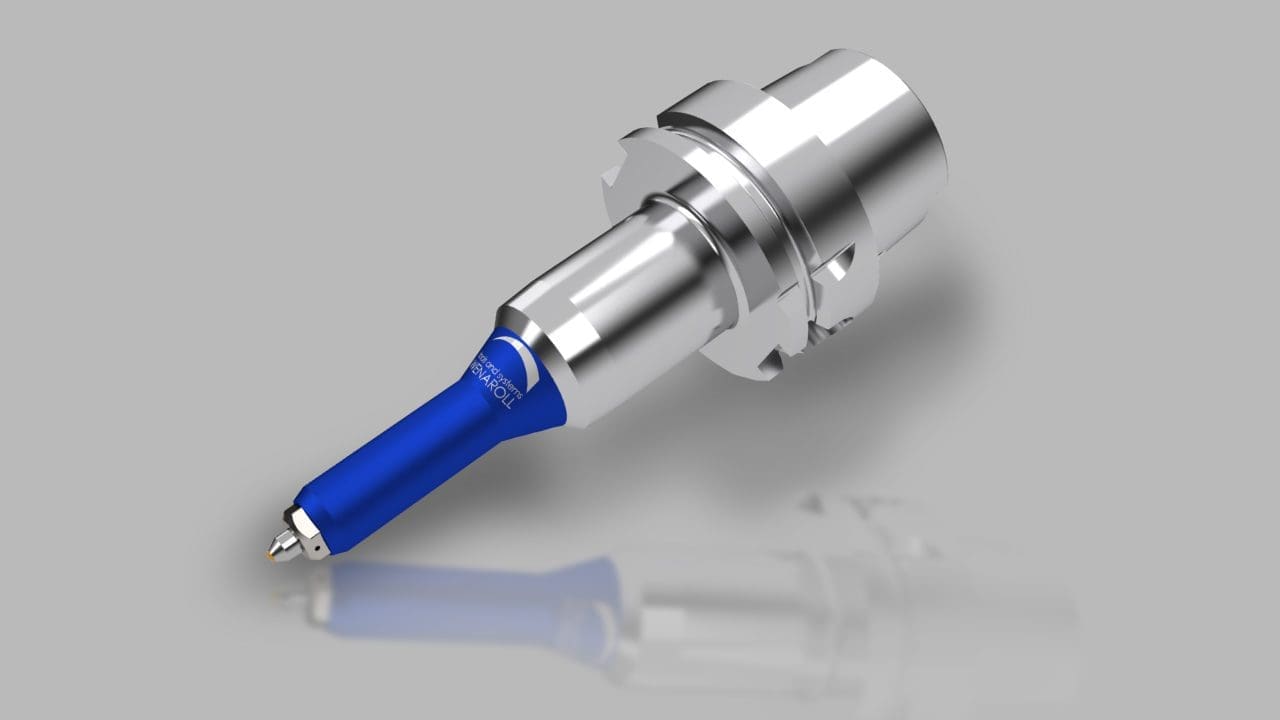

Tool structure

The Wenaroll Single Roller Burnishing Tools type ERGK consist of a tool body with a detachable roller mount, as well as a tool shank suited for your application.

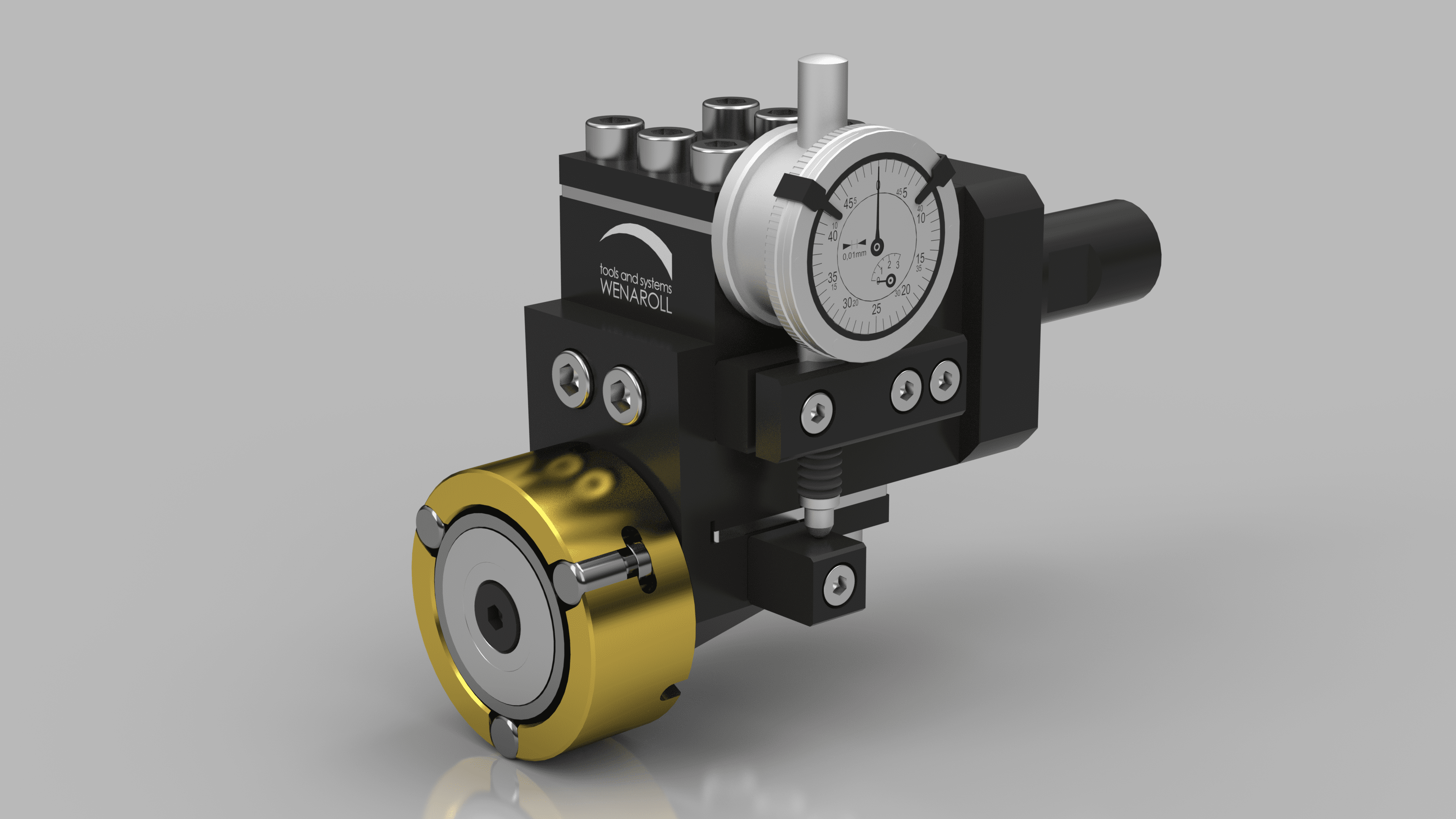

The tool has a site mounted dial indicator, which displays the spring deflection. With the provided chart you can adjust the roller force to produce the surface you need.

The standard tool provides a roller force of up to 4.000N, if more force is necessary you can order ERGK-1 or ERGK-3 which provide roller forces of up to 10.000N.

- Type ERGK : lateral surface right to left with up to 4.000N

- Type ERGK-1 : lateral surface right to left with up to 10.000N

- Type ERGK-3 : lateral surface left to right with up to 10.000N

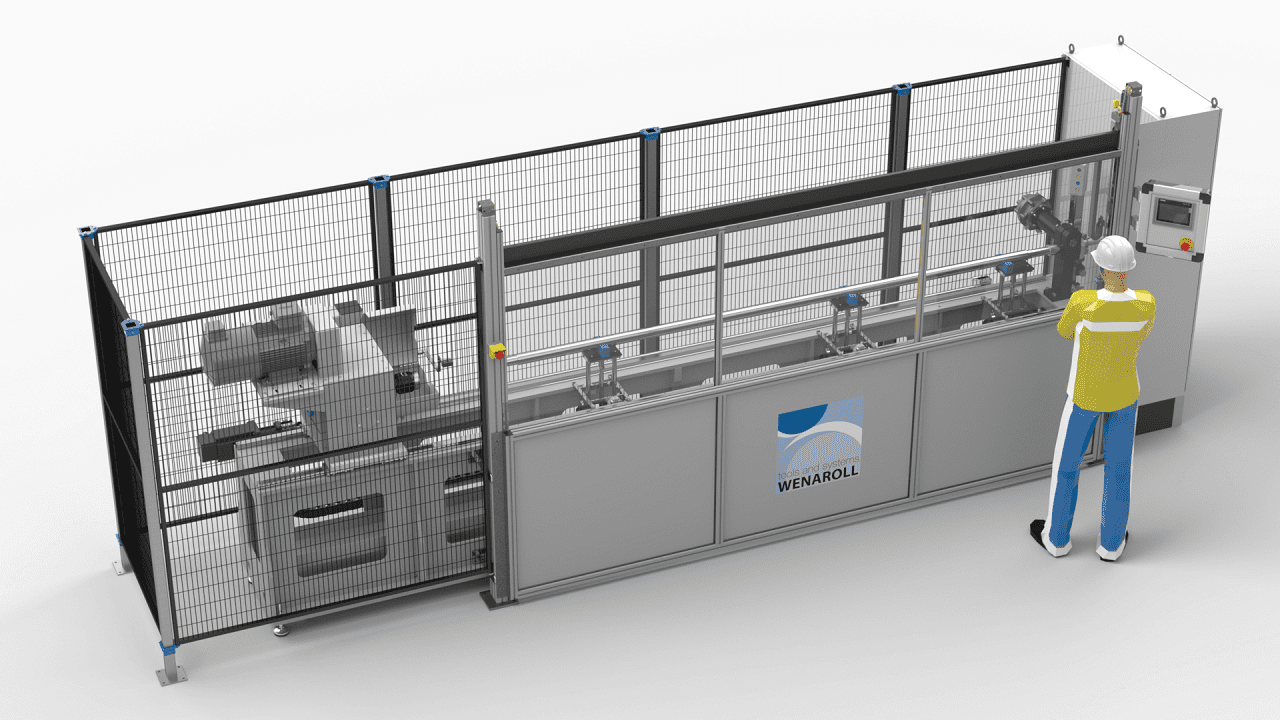

Process

All metal materials up to a yield strength of 1.400 N/mm² and a maximum hardness of 45 HRC can be process with this tool. During the process the work piece must rotate, a tool rotation is not possible.

Operation is possible on all kinds of production machines conventional as well as CNC. The force required for a successful burnishing operation is provided by the machine axis and is precisely adjusted with an indicator dial.

The lubrication required can be provided by the machine, with either oil or emulsion as lubricant. The circumferential speed of the tools can go up to 150 m/min , the feed can vary between 0,1 mm/R and 1 mm/R.